Precision shunt resistor and manufacturing method thereof

A shunt resistor, precision technology, applied in the direction of resistors, non-adjustable metal resistors, resistor manufacturing, etc., can solve the problems of insufficient thermal stability and reliability, large size of shunt resistors, low production efficiency, etc., to achieve reliable Increased performance, material saving, and reduced contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

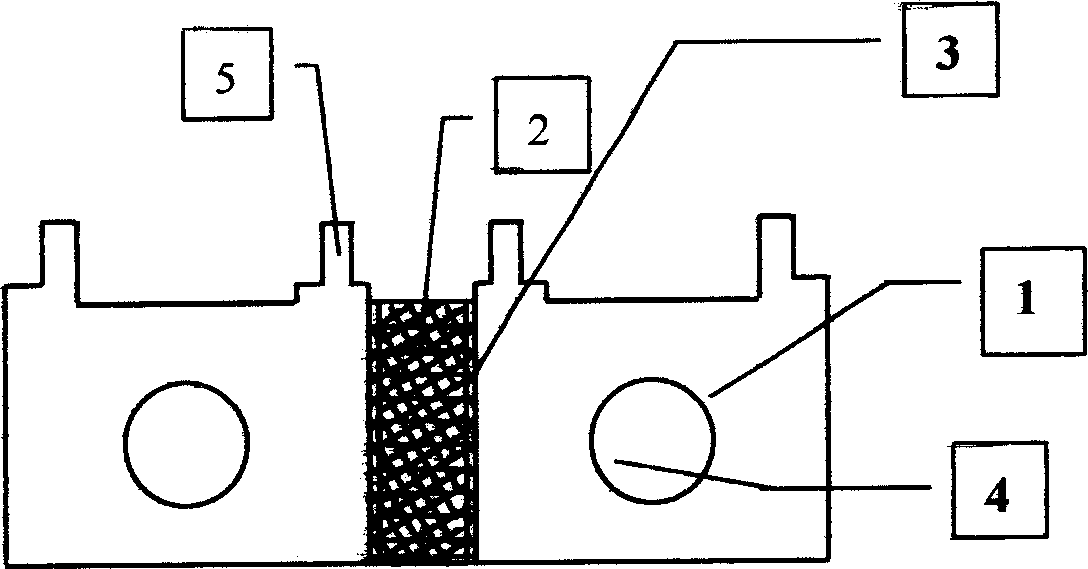

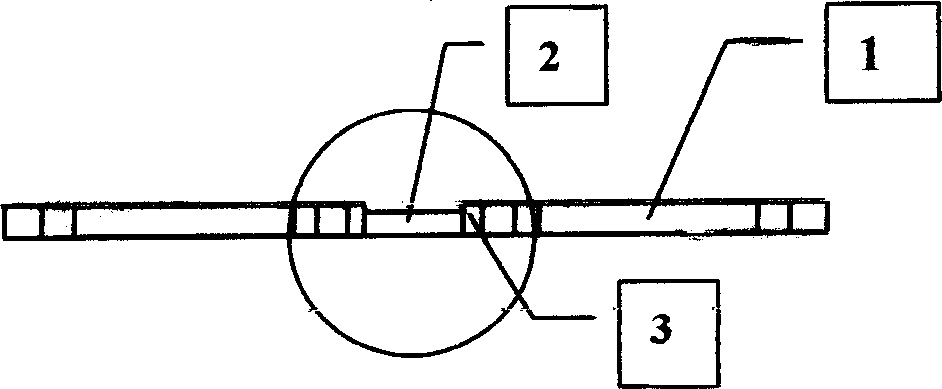

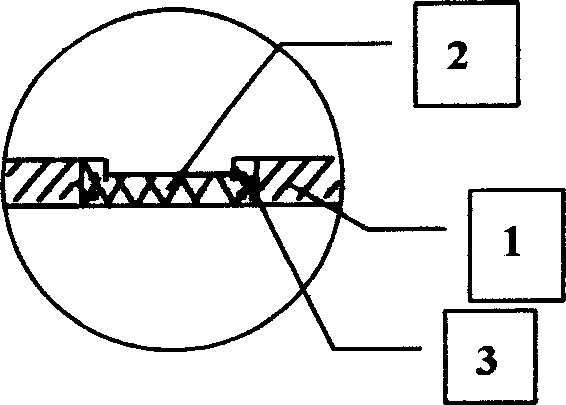

[0015] The specific implementation of the precision shunt resistor provided by the present invention and its production method is as follows: first, the width and thickness of the manganin strip are selected according to the resistance value and the rated current of the shunt resistor, and the composition of the manganese copper is that Mn is 11%- 13%, Ni is 2%-5%, the rest is Cu, the temperature coefficient is lower than 20ppm, and then select the copper strip with the same thickness as the manganese copper strip, and clean the manganese copper strip and the copper strip with cleaning agent Treatment, remove the surface oil, put the two into the vacuum electron beam welding machine in parallel, at a vacuum of 10 -2 -10 -4 Pa, the anode voltage is 30-150KV, the electron beam current is 10mA-1A, and the focus diameter is less than 1mm for vacuum electron beam welding. The focus position of the electron beam is 1 / 3 of the thickness of the strip from the surface of the weldment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com