Violet light excitated bicomponent three basic colour fluorescent powder and its preparation method

A two-component, three-primary color technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

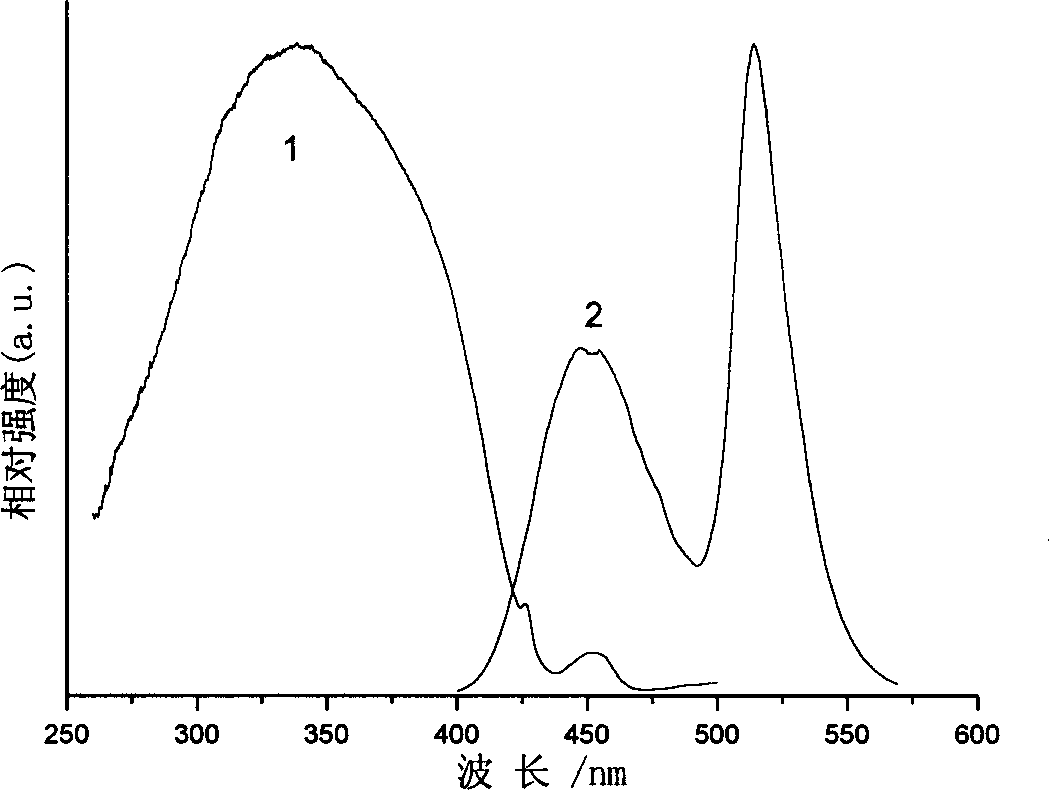

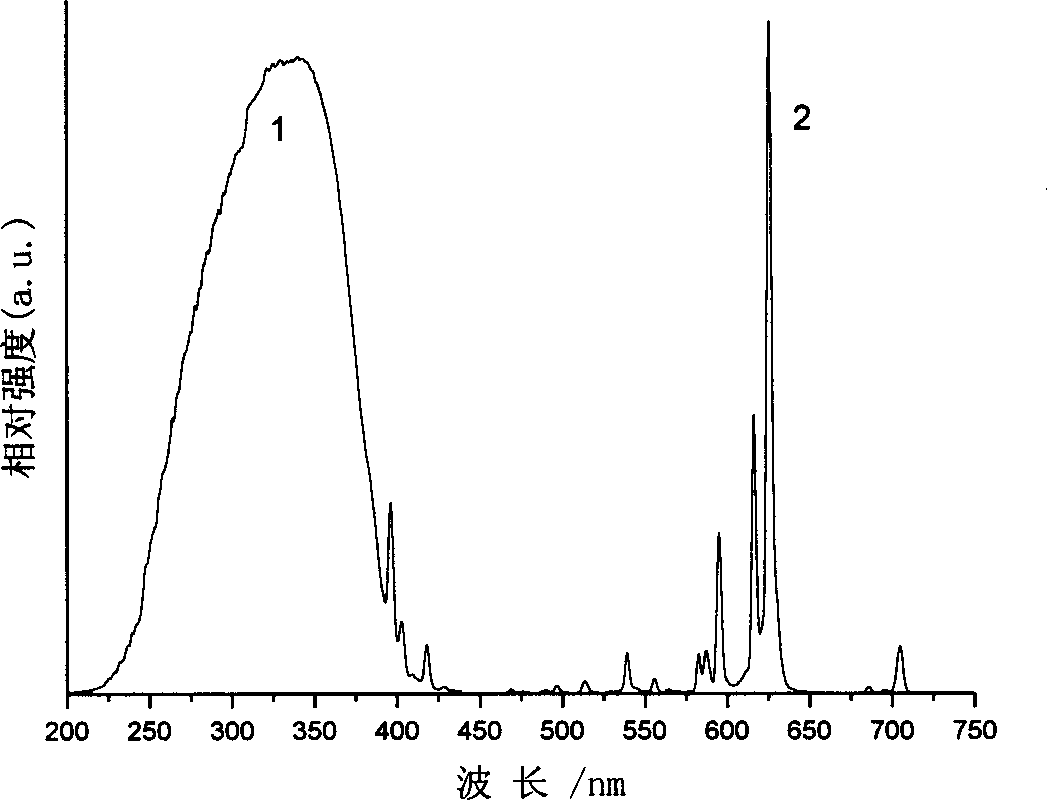

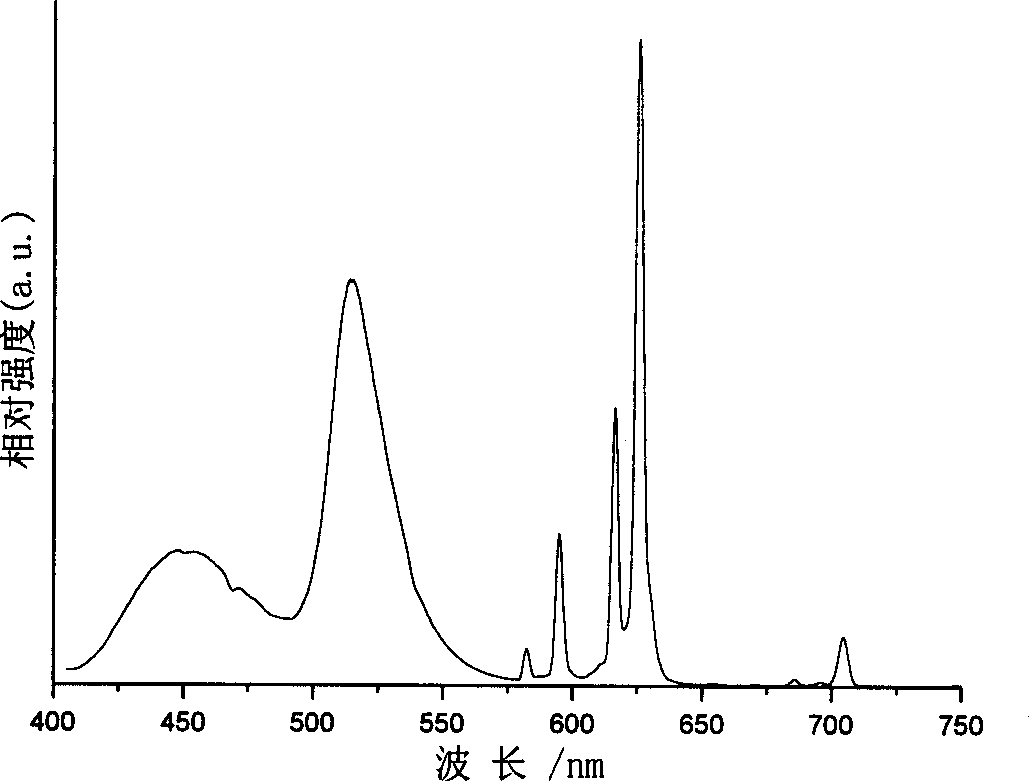

[0020] 1. 3.9000g Al(OH) 3 , 0.4686g basic magnesium carbonate, 0.9374g barium carbonate, 0.0858g manganese acetate, 0.0440g europium oxide, and 0.2110g lithium fluoride, ground, mixed evenly, and calcined at 1300°C for 4 hours under a reducing atmosphere to obtain light blue-green Powder Ba 0.95 Mg 0.96 Al 10 o 17 :0.05Eu 2+ , 0.04Mn 2+ .

[0021] 2. 3.9000g Al(OH) 3 , 0.4989g basic magnesium carbonate, 0.9768g barium carbonate, 0.0123g manganese acetate, 0.0088g europium oxide, and 0.2110g LiF, ground, mixed evenly, and calcined at 1400°C for 3 hours under a reducing atmosphere to obtain light blue-green powder Object Ba 0.99 Mg 0.99 Al 10 o 17 : 0.01Eu 2+ , 0.01Mn 2+ .

[0022] 3. 3.9000g Al(OH) 3 , 0.3779g basic magnesium carbonate, 0.7894g barium carbonate, 0.3064g manganese acetate, 0.1760g europium oxide, and 0.2110g LiF, ground, mixed evenly, and calcined at 1500°C for 2 hours under a reducing atmosphere to obtain light blue-green powder Object Ba 0.80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com