Mn-doped aluminum nitride-based red phosphor powder and preparation method of red phosphor powder

A red phosphor and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost, complicated preparation process, restricting the wide application of red nitride phosphors, etc., and achieve low cost and good repeatability. , The effect of protecting the porous graphite crucible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

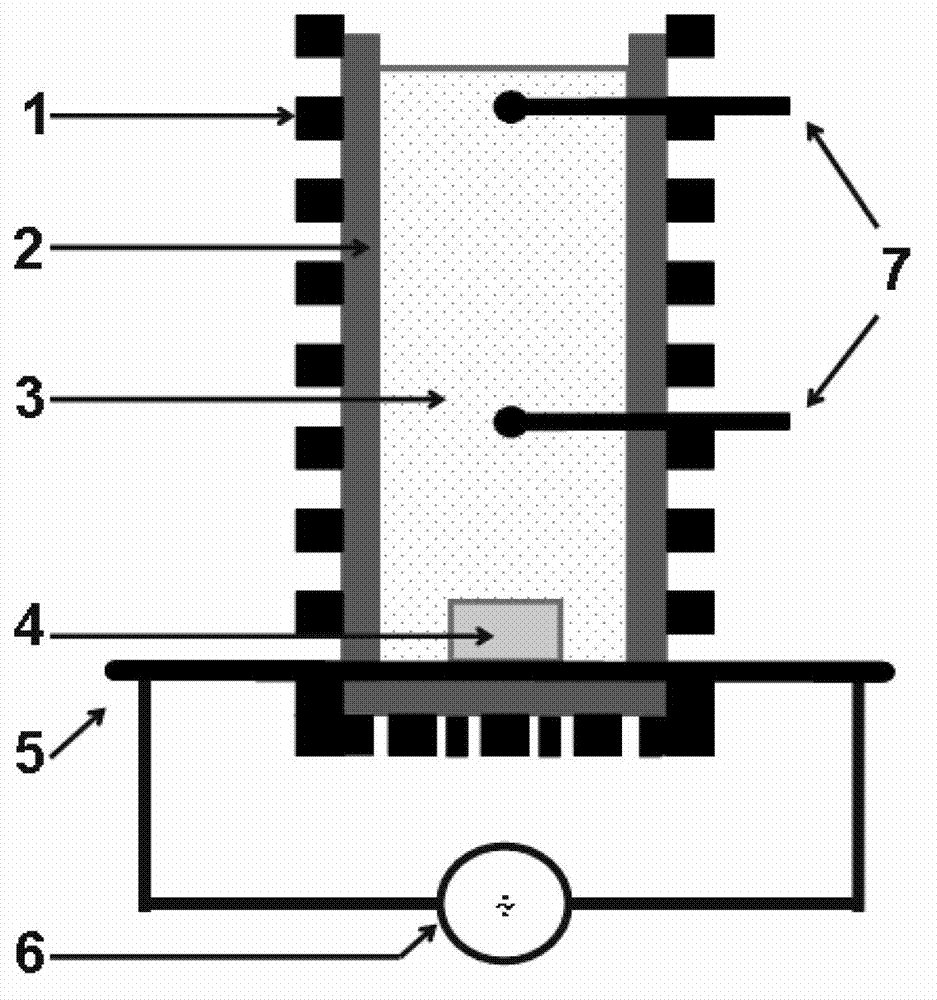

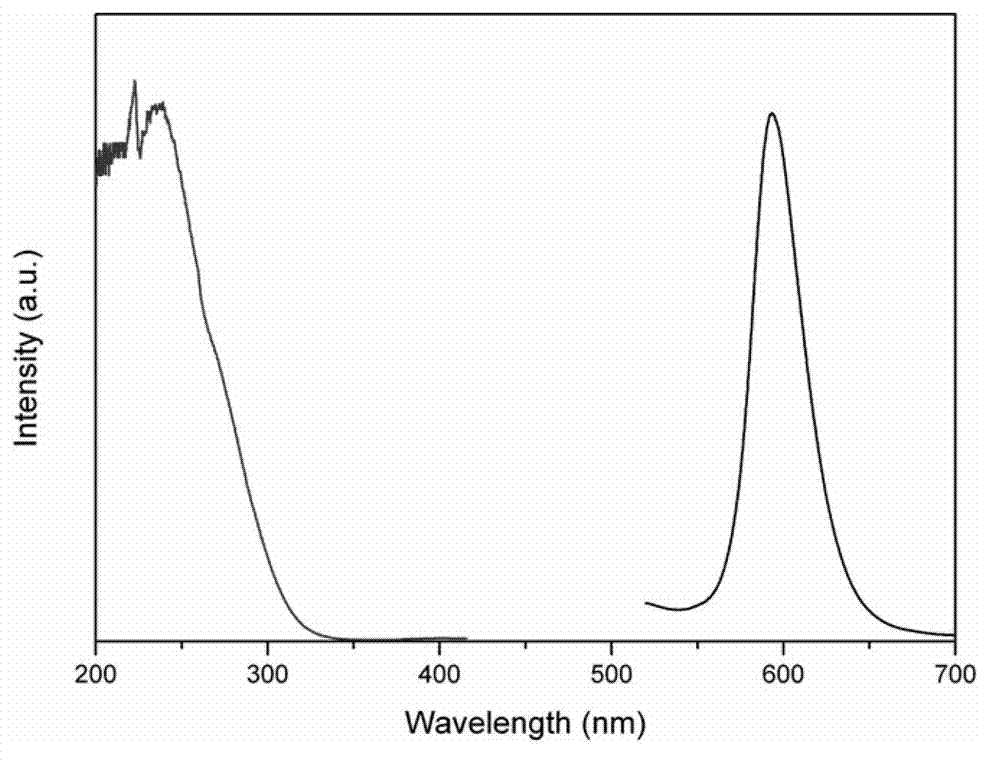

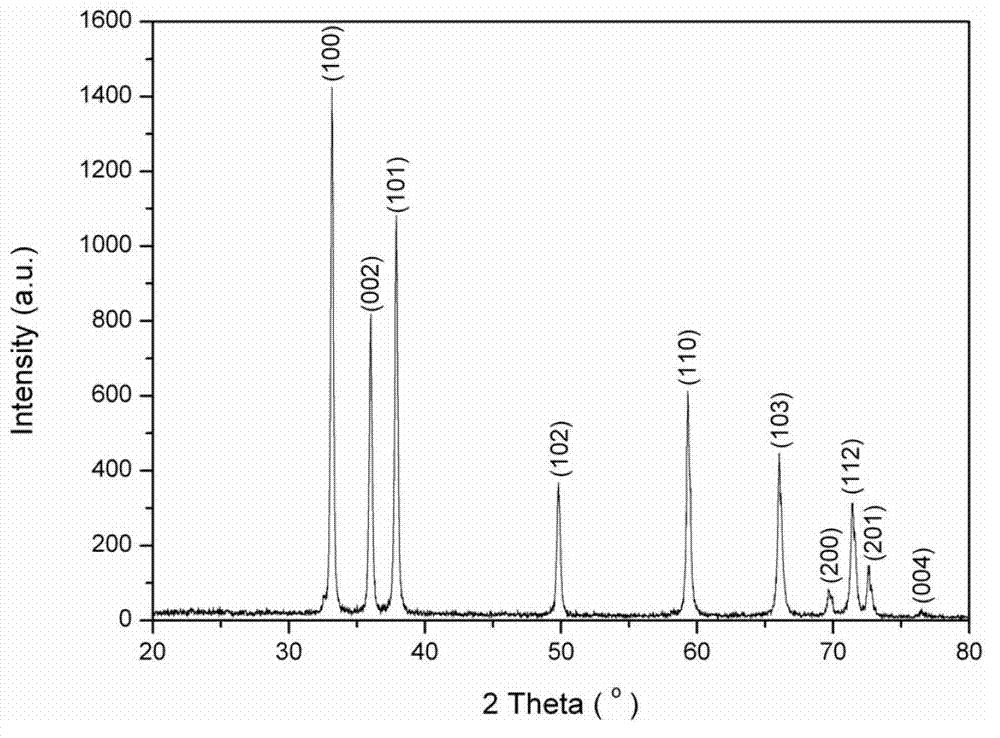

[0033] Composition of Al according to the chemical formula 1-x N:Mn x , take x=0.03, the mass ratio of Al powder and AlN powder is 4:6, that is, mix 7.762 grams of Al powder, 11.641 grams of AlN powder, and 0.629 grams of MnO and pass through a 100-mesh sieve. Put the mixed powder into a porous graphite crucible protected by a 3 mm thick graphite carbon felt, then put the porous graphite crucible into a high-pressure reaction vessel, and the high-pressure reaction vessel is evacuated to 10 -1 Pa, then fill with 1.0MPa purity and be 99.99% high-purity nitrogen; Light the igniter block that is placed on the bottom of the powder by the graphite paper strip and ignite, and the igniter block is a mixture of titanium powder and carbon powder in a 1:1 molar ratio The mixed powder is compressed, and the graphite paper belt is energized for 5 seconds under the condition of a energizing current of 24A and a voltage of 60V to make the combustion reaction occur. After the reaction, the ...

Embodiment 2

[0038] Composition of Al according to the chemical formula 1-x N:Mn x , take x=0.01, the mass ratio of Al powder and AlN powder is 6:4, that is, 11.570 grams of Al powder, 7.713 grams of AlN powder, 0.717 grams of MnCO 3 And pass through 200 mesh sieve. Put the mixed powder into a porous graphite crucible protected by a 2mm thick graphite carbon felt, then put the porous graphite crucible into a high-pressure reaction vessel, and the high-pressure reaction vessel is evacuated to 10 2Pa, and then fill with 3MPa purity of 99.999% high-purity nitrogen; ignite the igniter block placed at the bottom of the powder through the graphite paper strip to ignite, the igniter block is a mixture of titanium powder and carbon powder in a 1:1 molar ratio The graphite paper strip is energized for 10 seconds under the condition of energizing current of 20A and voltage of 70V to make the combustion reaction occur. After the reaction, the product in the porous graphite crucible was taken out a...

Embodiment 3

[0040] Composition of Al according to the chemical formula 1-x N:Mn x , take x=0.1, the mass ratio of Al powder and AlN powder is 3:7, that is, 4.716 grams of Al powder, 11.004 grams of AlN powder, 4.287 grams of MnO 2 Mix well and pass through a 300-mesh sieve. Put the mixed powder into a porous graphite crucible protected by a 4mm thick graphite carbon felt, then put the porous graphite crucible into a high-pressure reaction vessel, and the high-pressure reaction vessel is evacuated, and then filled with 0.5MPa nitrogen with a purity of 99.9%; The paper tape ignites the igniter block placed at the bottom of the powder to ignite. The igniter block is pressed from a mixture of titanium powder and carbon powder in a molar ratio of 1:1. Under the conditions of a current of 30A and a voltage of 50V The graphite paper strip was energized for 8 seconds to cause the combustion reaction to take place. After the reaction, the product in the porous graphite crucible was taken out an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com