Construction equipment for generating horizontal jet grouting reinforcing body by injecting double-liquid liquid with high-pressure

A technology of high-pressure spraying and construction equipment, which is applied in the direction of mining equipment, shaft equipment, soil protection, etc., can solve the problems of reduced construction efficiency, reinforcement failure, and the inability to rotate 360 degrees of drilling spray rods, etc., to achieve comprehensive construction cost reduction, rotation Increased spraying construction speed, convenient and reliable equipment processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

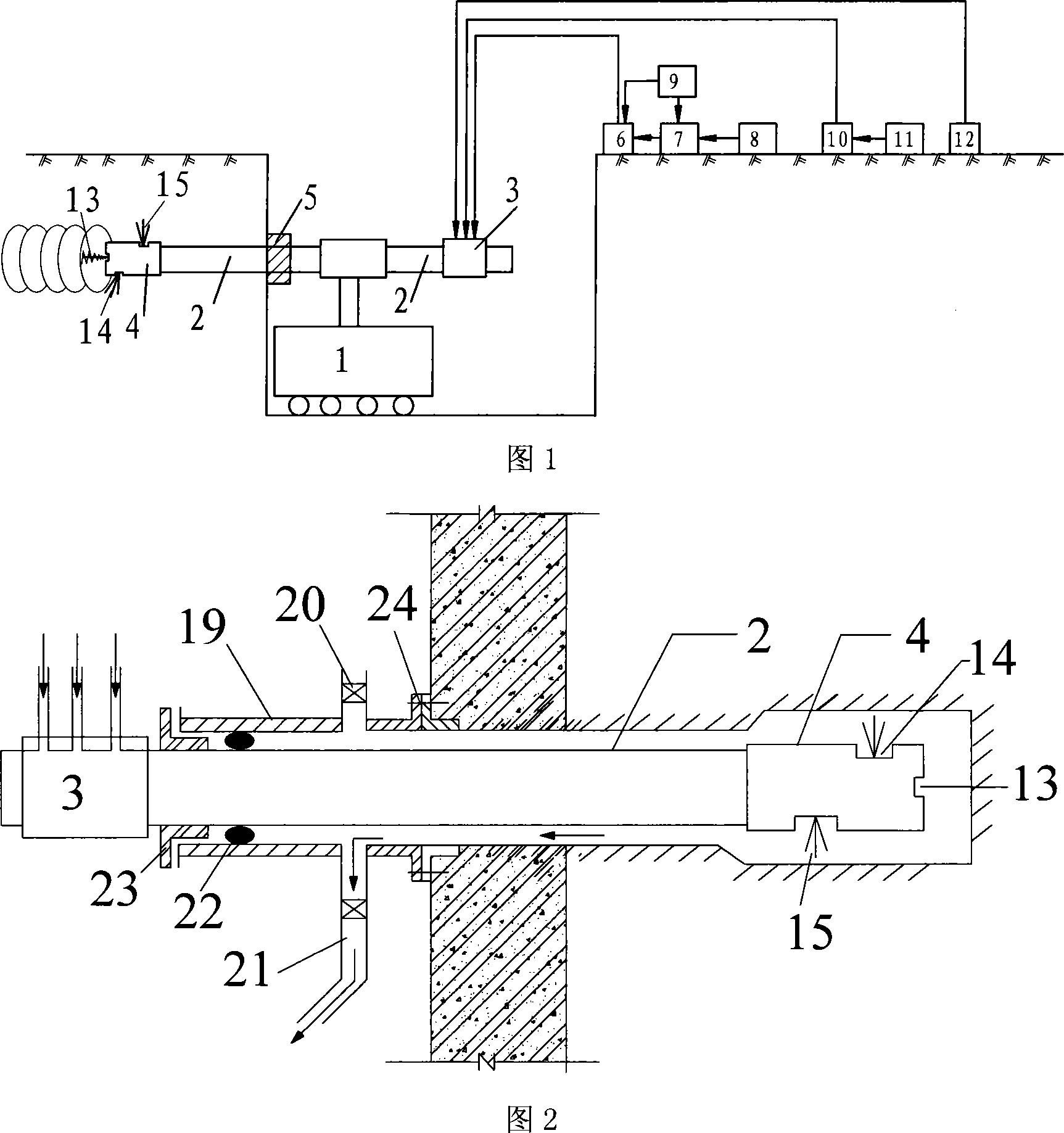

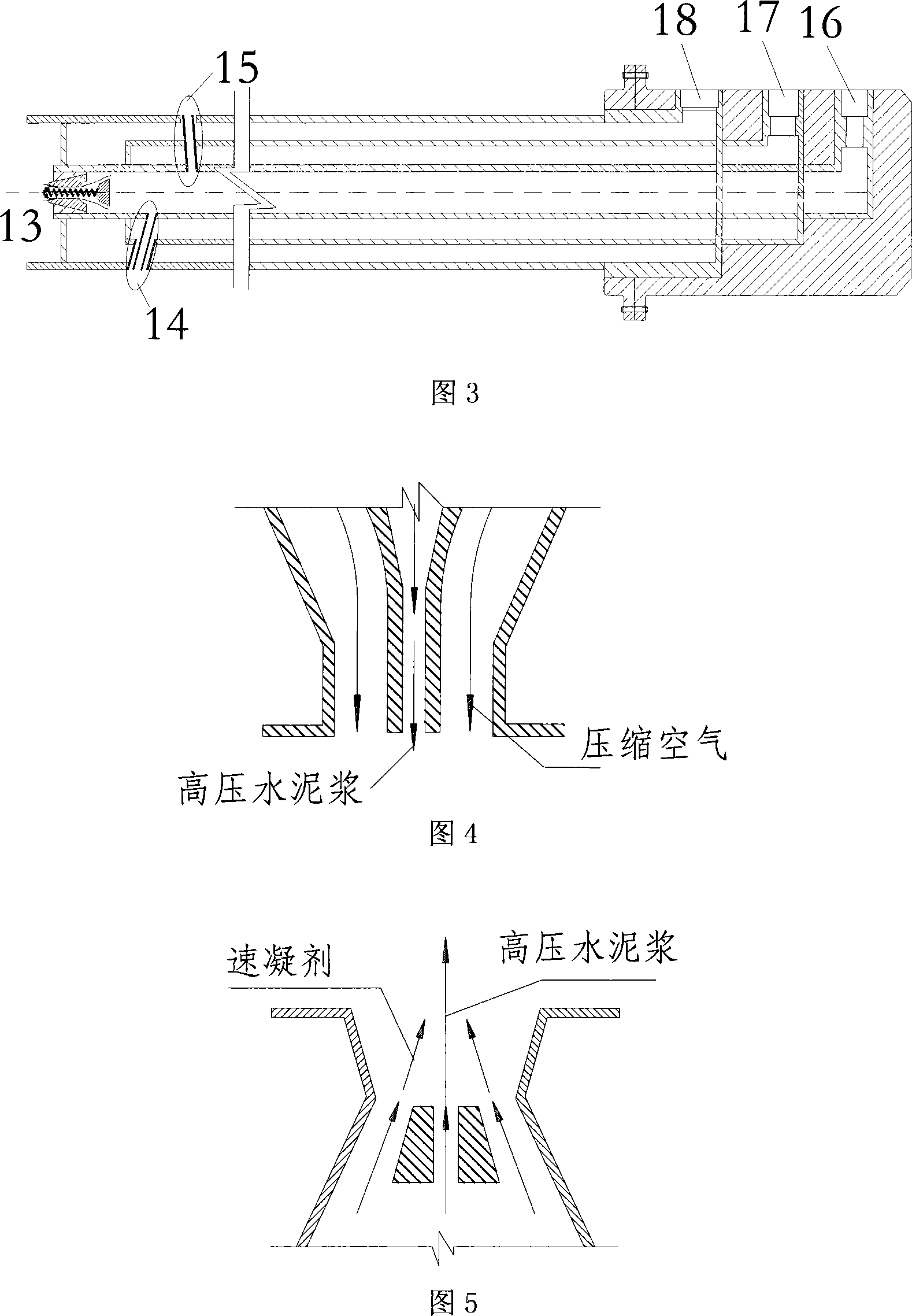

[0029]As shown in Figure 1, this embodiment is the equipment composition and connection method of triple tube double liquid horizontal rotary spraying, including: horizontal drilling machine 1, triple tube drilling spray rod 2, flow divider 3, multi-functional nozzle 4, orifice sealing device 5. High-pressure pump 6, low-pressure pump 10, air compressor 12, and peripheral equipment mixing station 7, cement storage silo 8, water tank 9, accelerator bucket 11, etc. The bracket of horizontal drilling rig 1 supports triple pipe drilling and spraying The rod 2 is driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com