Dynamotor rotor voltage and current measuring method and its device

A technology for generator rotors and measuring devices, which is applied to measuring devices, measuring current/voltage, and measuring electrical variables, etc., can solve the problems of inability to measure accurately in transient processes, being susceptible to electromagnetic interference, and reducing measurement accuracy, etc., to achieve Excellent anti-electromagnetic interference performance, excellent anti-electromagnetic interference characteristics, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

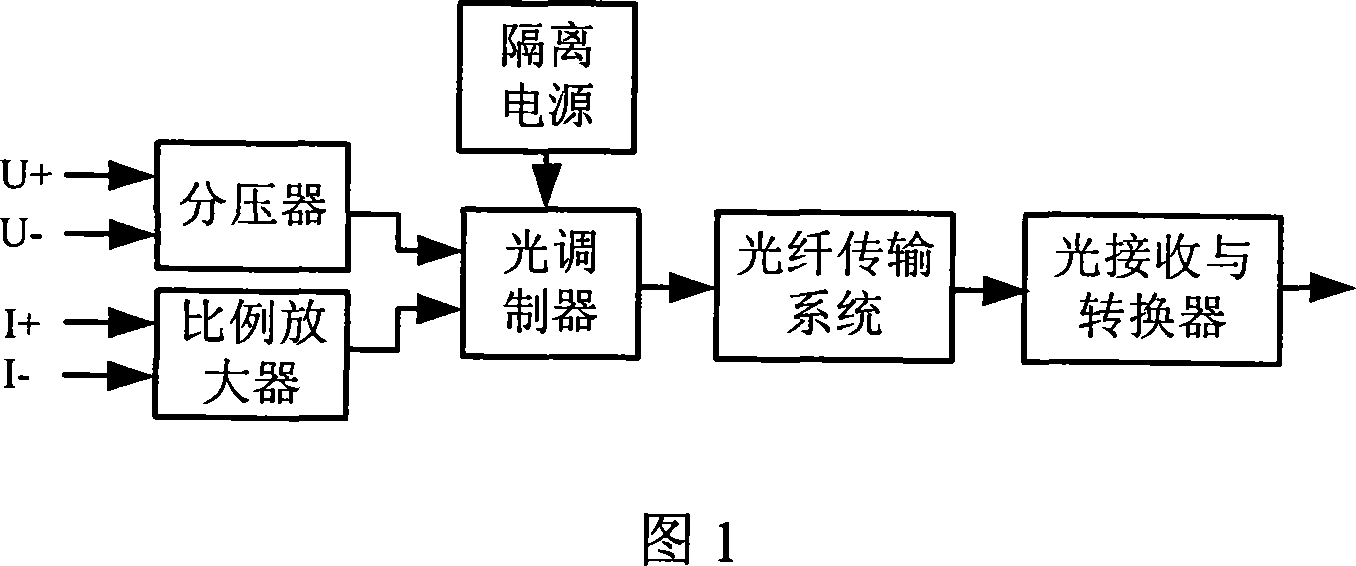

[0028] The method for measuring generator rotor voltage and current proposed by the present invention first collects the voltage signal and current signal of the generator rotor; converts the collected voltage signal and current signal into optical signals respectively; transmits and receives the above-mentioned optical signals over a long distance, and The received optical signal is converted into an electrical signal and output.

[0029] The structural block diagram of the generator rotor voltage and current measuring device proposed by the present invention is as shown in Figure 1, including

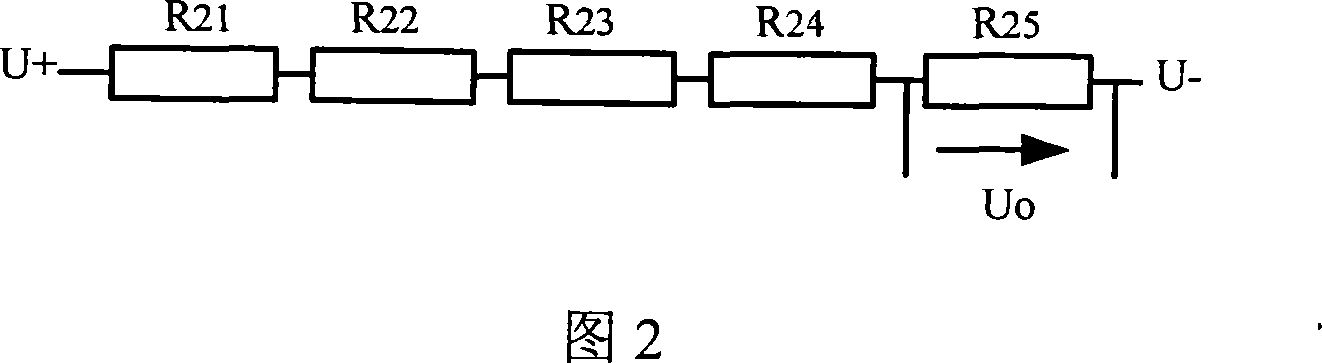

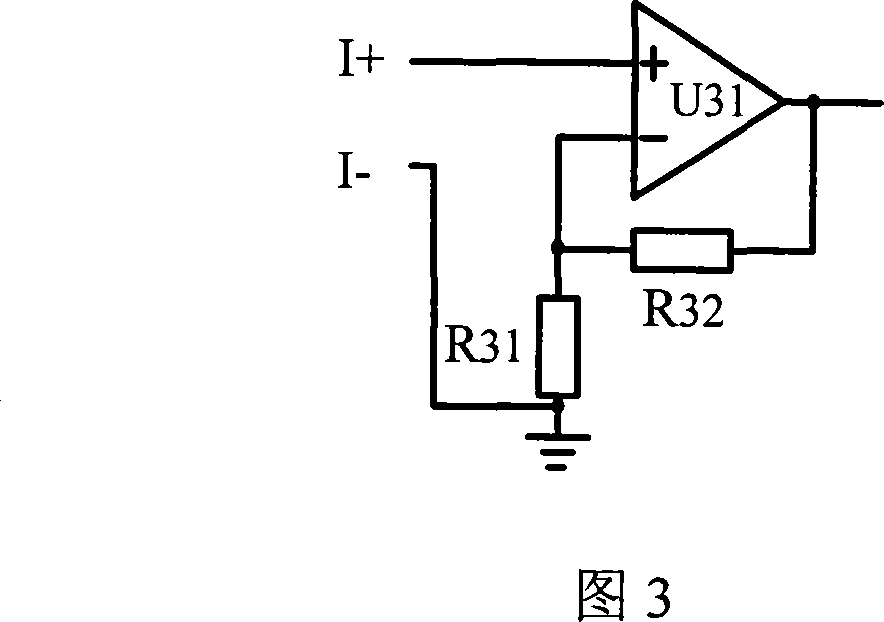

[0030] A voltage divider and a proportional amplifier are respectively used to collect the voltage signal and current signal of the generator rotor, and the voltage divider and the proportional amplifier are respectively connected to the optical modulator;

[0031] The optical modulator is used to convert the voltage signal and the current signal into optical signals respectively;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com