Manufacturing method of two-in-one structure inductor with air gap formed in side surface

A manufacturing method and side surface technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor cooling, transformer/inductor magnetic core, etc. Interference, small overload capacity of round copper wire and other problems, to achieve the effect of strong anti-electromagnetic interference performance, small DC loss, and good conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The manufacturing method of the two-in-one structure inductor with an air gap on the side surface of this embodiment includes the following steps:

[0054] (1) Preparation of accessories:

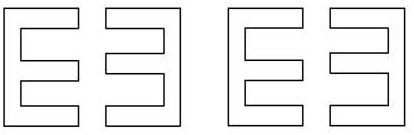

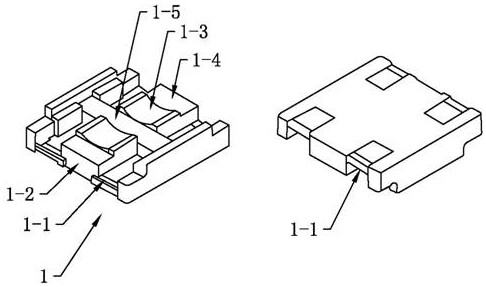

[0055] Ⅰ. Injection molding of the base: Use the injection molding machine to produce the base raw materials. The base has four electrode slots and a partition wall in the middle. The two electrode slots on the same side of the partition form a group of electrode slots. Each group There is a cushion seat between the two electrode slots of the electrode slot. The cushion seat is provided with an arc-shaped concave surface. The outer side of the arc-shaped concave surface has a magnetic core adhesive area. The base structure sees image 3 ;

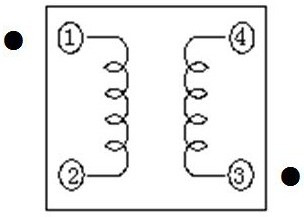

[0056] Ⅱ. Electrode forming: The cut metal sheet is punched and formed to form an electrode. The electrode is in the shape of a U-shaped clip and has a bent Z-shaped extension piece. The electrode is used as a conductive carrier connecting the pr...

Embodiment 2

[0071] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. It also includes the electrical test step (9), testing the inductance value, current resistance value and withstand voltage degree, among which, ① test inductance condition: 100KHz 0.25V, inductance value 1.0μH±20%; ② test DC resistance condition: at 20 ℃ D.C.R. value is less than 7.0 mΩ; ③ withstand voltage test: coil-core, DC voltage 120V, current 2 mA, time 2 seconds. Other electrical characteristics can be tested according to customer needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com