Flame-retardant insulating material

A technology of flame-retardant insulating materials and insulating layers, applied in layered products, glass/slag layered products, synthetic resin layered products, etc., can solve the problems of heat resistance, environmental pollution, easy breakdown of flame-retardant insulating materials Problems, to achieve the effect of high tensile strength, excellent performance, excellent anti-electromagnetic interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

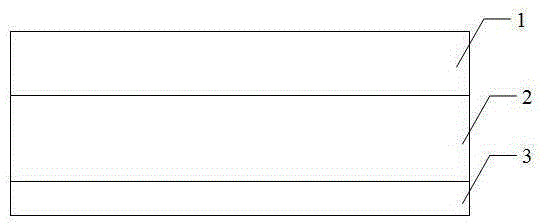

[0024] Flame retardant insulating material, including PTT fiber base layer 1, insulating layer 2 and heat insulating layer 3, insulating layer 2 includes raw materials of the following weight components: 30kg organic silicon resin, 15kg organic silicon crosslinking agent, 15kg silicon dioxide, 11kg hydrogen Silicon oxide, 10kg magnesium hydroxide, 6kg iron oxide, 5kg barium sulfate, 5kg magnesium silicate, 3kg talcum powder, 3kg lubricant, 4kg antioxidant, 2kg compatibilizer and 1kg silicone leveling agent, heat insulation layer 3 for the glass fiber layer. Wherein, antioxidant is antioxidant 3114. The compatibilizer is ST-1 compatibilizer. The lubricant is paraffin. The thickness ratio of PTT fiber base layer 1, insulation layer 2 and heat insulation layer 3 is 2:4:1.

[0025] Test Results:

[0026] Combustion or heating test: test the gas released, no toxic gas was found, and it has the characteristics of low smoke, non-toxic, halogen-free and flame retardant;

[0027] ...

Embodiment 2

[0030] Flame retardant insulating material, including PTT fiber base layer 1, insulating layer 2 and heat insulating layer 3, insulating layer 2 includes raw materials of the following weight components: 40kg organic silicon resin, 20kg organic silicon crosslinking agent, 20kg silicon dioxide, 16kg hydrogen Silicon oxide, 15kg magnesium hydroxide, 8kg iron oxide, 7kg barium sulfate, 6kg magnesium silicate, 4kg talcum powder, 4kg lubricant, 5kg antioxidant, 3kg compatibilizer and 2kg silicone leveling agent, heat insulation layer 3 for the glass fiber layer. Among them, the antioxidant is antioxidant 168. The compatibilizer is ST-1 compatibilizer. The lubricant is paraffin. The thickness ratio of PTT fiber base layer 1, insulation layer 2 and heat insulation layer 3 is 3:6:2

[0031] Test Results:

[0032] Combustion or heating test: test the gas released, no toxic gas was found, and it has the characteristics of low smoke, non-toxic, halogen-free and flame retardant;

[0...

Embodiment 3

[0036] Flame retardant insulating material, including PTT fiber base layer 1, insulating layer 2 and heat insulating layer 3, insulating layer 2 includes raw materials of the following weight components: 35kg organic silicon resin, 17kg organic silicon crosslinking agent, 18kg silicon dioxide, 13kg hydrogen Silicon oxide, 12kg magnesium hydroxide, 7kg iron oxide, 6kg barium sulfate, 5kg magnesium silicate, 3kg talcum powder, 3kg lubricant, 4kg antioxidant, 2kg compatibilizer and 1kg silicone leveling agent, insulation layer 3 for the glass fiber layer. Wherein, antioxidant is antioxidant 3114. The compatibilizer is ST-1 compatibilizer. The lubricant is paraffin. The thickness ratio of PTT fiber base layer 1, insulation layer 2 and heat insulation layer 3 is 2.5:5:1.5.

[0037] Test Results:

[0038] Combustion or heating test: test the gas released, no toxic gas was found, and it has the characteristics of low smoke, non-toxic, halogen-free and flame retardant;

[0039] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com