Reaction system for quickly evaluating Claus unit tail gas hydrodesulphurization catalyst

A Claus tail gas and hydrodesulfurization technology, applied in the field of chemical research and chemical equipment, can solve the problems of low efficiency, long evaluation period, unfavorable catalyst development and research, etc., and achieves strong versatility, fast evaluation speed, and economical The effect of cost and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

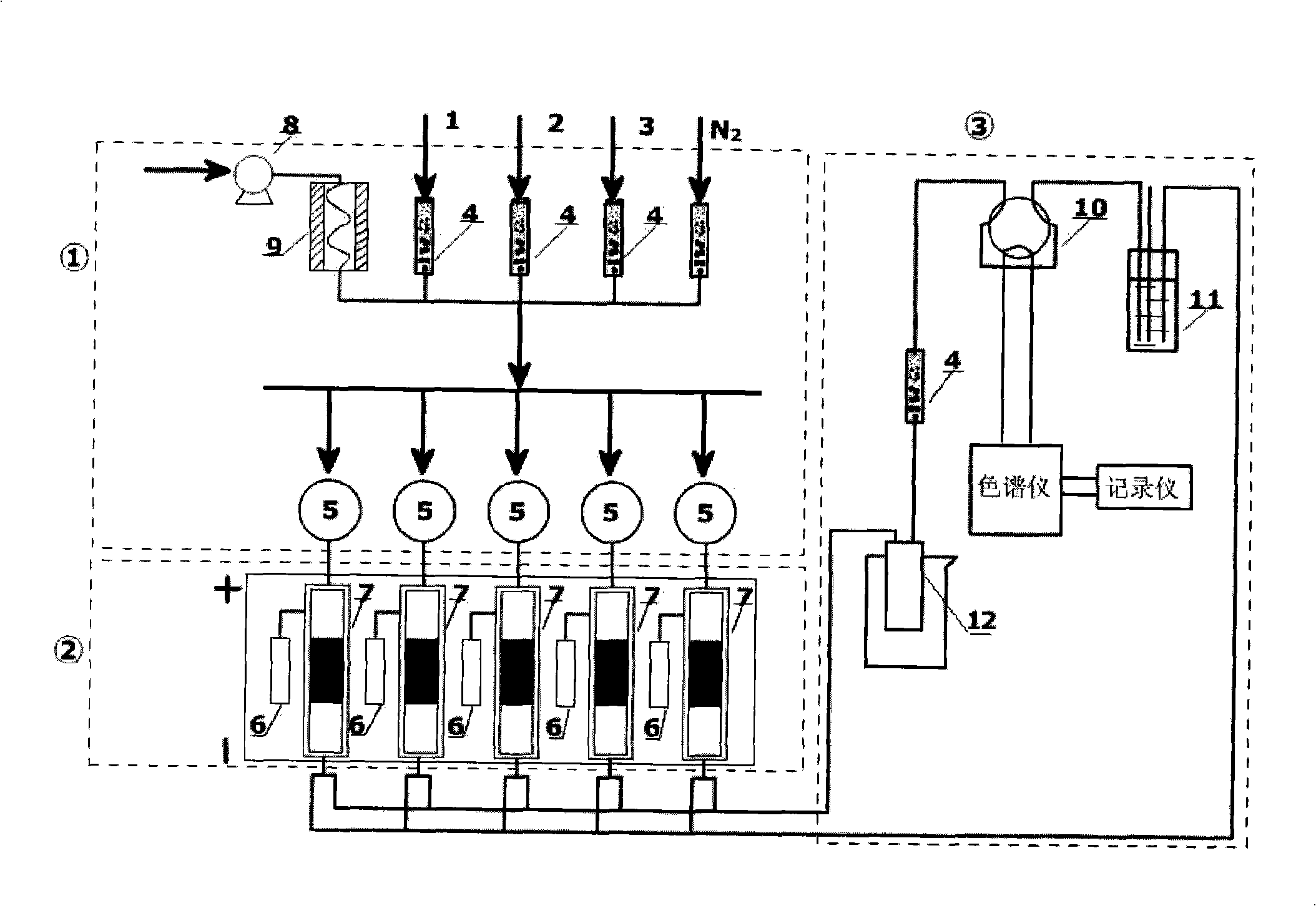

[0029] Example 1: SO of Claus Tail Gas Hydrodesulfurization Catalyst 2 Hydrogenation activity evaluation

[0030] A parallel reactor consisting of three fixed-bed reactors 7 connected in parallel, each made of quartz glass tubes with a length of 60 cm and an inner diameter of 8 mm; and three flowmeters 5 (5a, 5b, 5c). Weigh 1 g of each of the three nickel-based catalysts used for Claus tail gas hydrodesulfurization, and place them in the middle constant temperature zones of the three reactors, and fill the top and bottom of the three reactors with inert quartz with a particle size of 20 to 40 mesh sand. Contains H 2After passing through the splitter, the mixed gas of S flows into three reactors at a rate of 15mL / min controlled by flow meters 5a, 5b, and 5c, and is pre-cured at 400°C for 2h. After the vulcanization is completed, the mixed gas 2 for hydrogenation reaction is passed into the three reactors at the flow rate of 50ml / min, 300ml / min, and 800ml / min respectively, an...

Embodiment 2

[0031] Example 2: CS of Claus Tail Gas Hydrodesulfurization Catalyst 2 Hydrolytic activity evaluation

[0032] A parallel reactor consisting of two fixed-bed reactors 7 connected in parallel, each made of quartz glass tubes with a length of 60 cm and an inner diameter of 8 mm; and two flowmeters 5 (5a, 5b). Weigh 1 g of each of the two cobalt-molybdenum catalysts used for the hydrodesulfurization of Claus tail gas, and place them in the middle constant temperature zones of the two reactors respectively. The top and bottom of the two reactors are filled with inert quartz with a particle size of 20 to 40 mesh sand. Contains H 2 After passing through the splitter, the mixed gas of S flows into two reactors at a rate of 15mL / min controlled by flow meters 5a and 5b, and is pre-cured at 400°C for 2h. After the vulcanization is over, the CS-containing catalyst used to investigate the hydrolysis activity of the catalyst is passed into the two reactors at a flow rate of 100ml / min. ...

Embodiment 3

[0033] Example 3: SO of Claus Tail Gas Hydrodesulfurization Catalyst 2 Hydrogenation activity and CS 2 Simultaneous evaluation of hydrolytic activity

[0034] A parallel reactor consisting of five fixed-bed reactors 7 connected in parallel, each made of quartz glass tubes with a length of 60 cm and an inner diameter of 8 mm; and five flowmeters 5 (5a, 5b, 5c, 5d, 5e). Weigh 1g each of 5 kinds of nickel-based catalysts used for Claus tail gas hydrodesulfurization, and place them in the middle constant temperature zones of the 5 reactors respectively. The top and bottom of the 5 reactors are filled with inert quartz with a particle size of 20-40 mesh sand. Contains H 2 After passing through the splitter, the mixed gas of S flows into five reactors at a rate of 15mL / min controlled by flow meters 5a, 5b, 5c, 5d, and 5e, and is pre-cured at 400°C for 2h. After the vulcanization is finished, pass into the reactors connected with the flowmeters 5a and 5b at the flow rate of 50ml / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com