Concrete jacking and refluxing system and construction method thereof

A technology of concrete roof and construction method, which is applied in the direction of construction, building structure, and construction material processing, etc. It can solve the problems of pump pipe blockage, long construction time, and waste of concrete, so as to improve construction efficiency, reduce waste of concrete, shorten The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

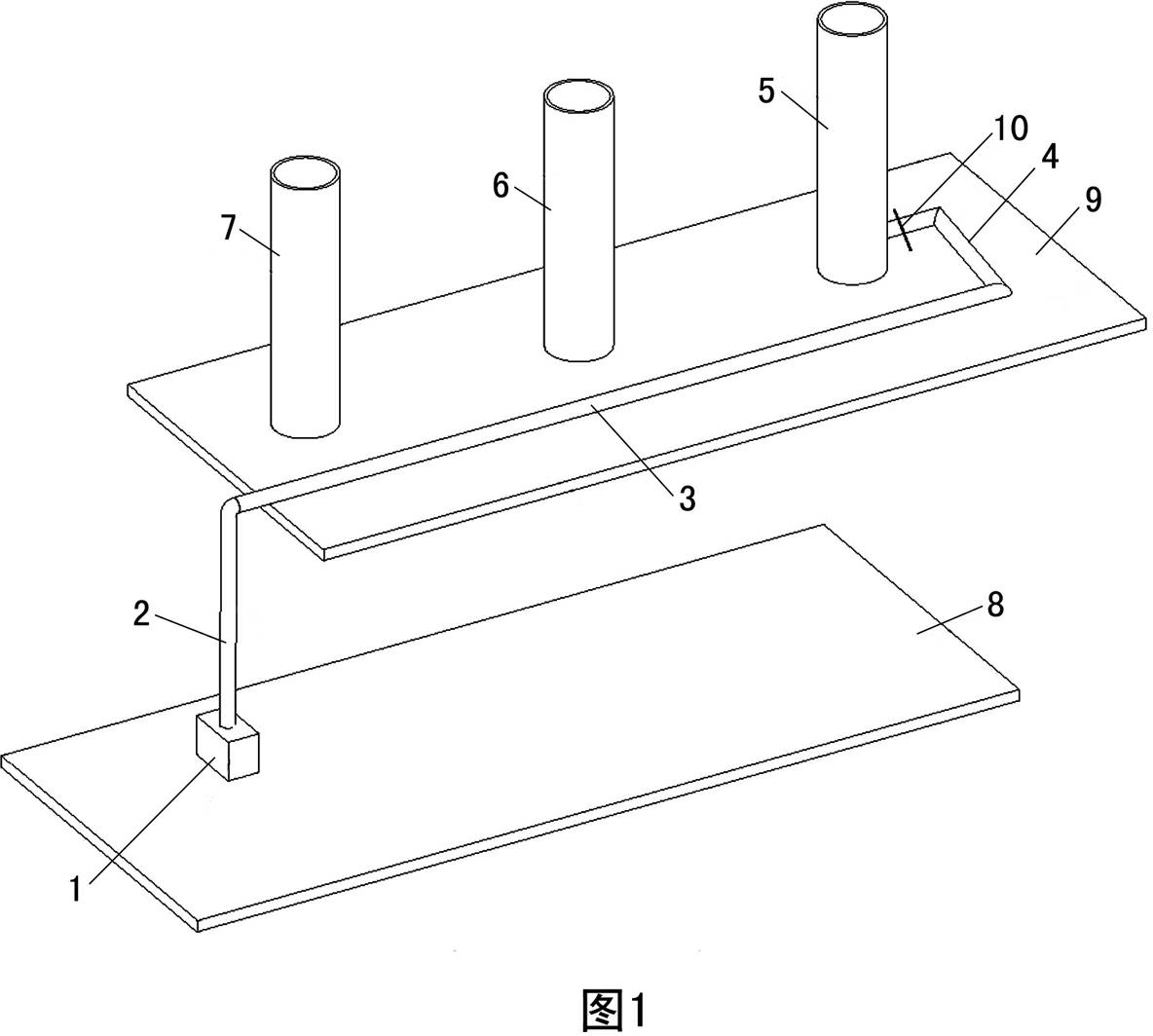

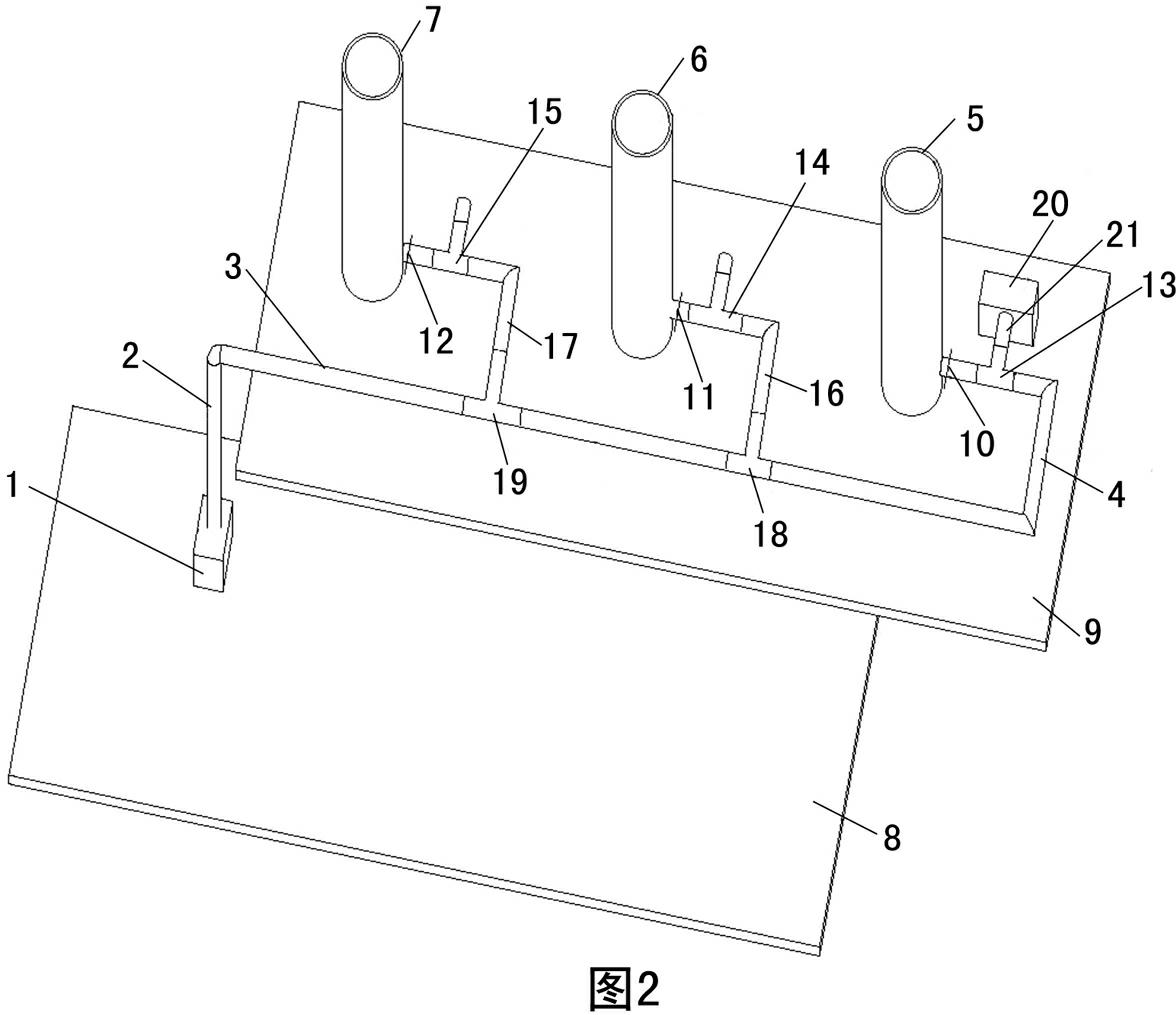

[0033] Examples see figure 2 As shown, this concrete jacking backflow system includes a concrete delivery pump 1 and a concrete delivery pipeline, and the concrete delivery pipeline includes a delivery pipe standpipe 2, a delivery pipe main pipe 3 and a delivery pipe branch pipe, wherein the delivery pipe main pipe 3 and the delivery pipe The branch pipes are all spliced by single-section pipes.

[0034] The number of the delivery pipe branches is the same as the number of steel pipe columns that need to be lifted, at least two, the delivery pipe main pipe 3 communicates with the first delivery pipe branch 4 in the delivery pipe branch, and the first delivery pipe branch 4 is in turn The check valve of the steel pipe column communicates with the hole on the lower pipe wall of the first steel pipe column 5 in the steel pipe column. Through the check valve of the steel pipe column, it communicates with the hole on the lower pipe wall of the remaining steel pipe column; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com