Fuzzy proportion integration differentiation (PID) control method and device for industrial environment high-precision air conditioner

An industrial environment, fuzzy control technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of fuzzy control, unsatisfactory, mathematical model cannot be established, etc., and achieve the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

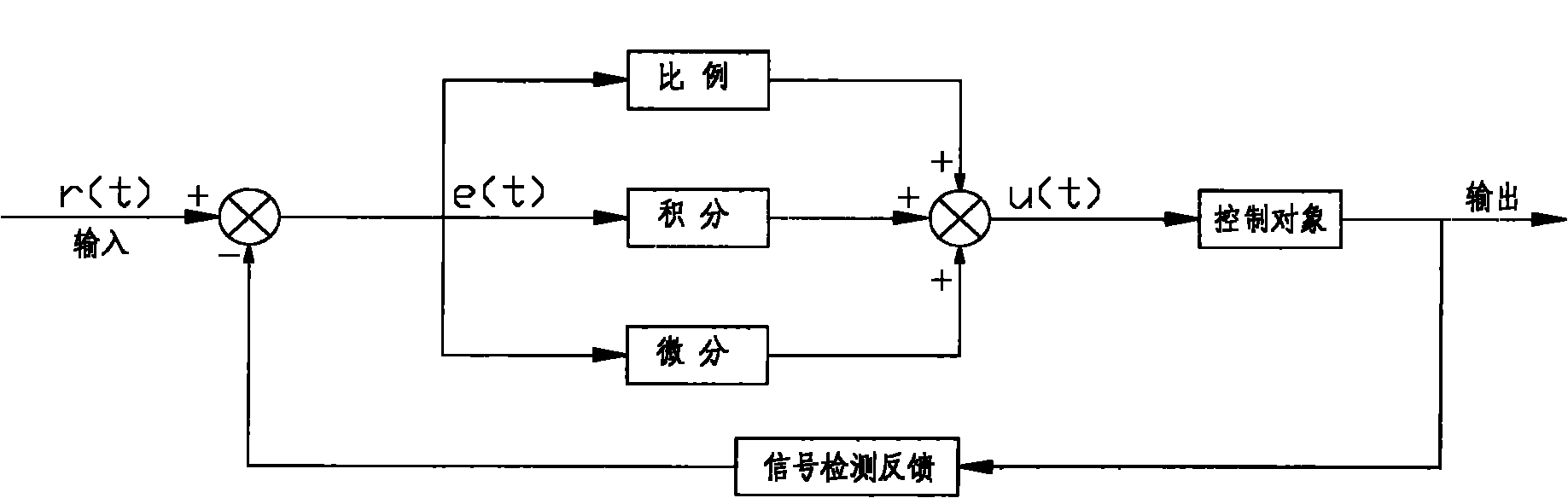

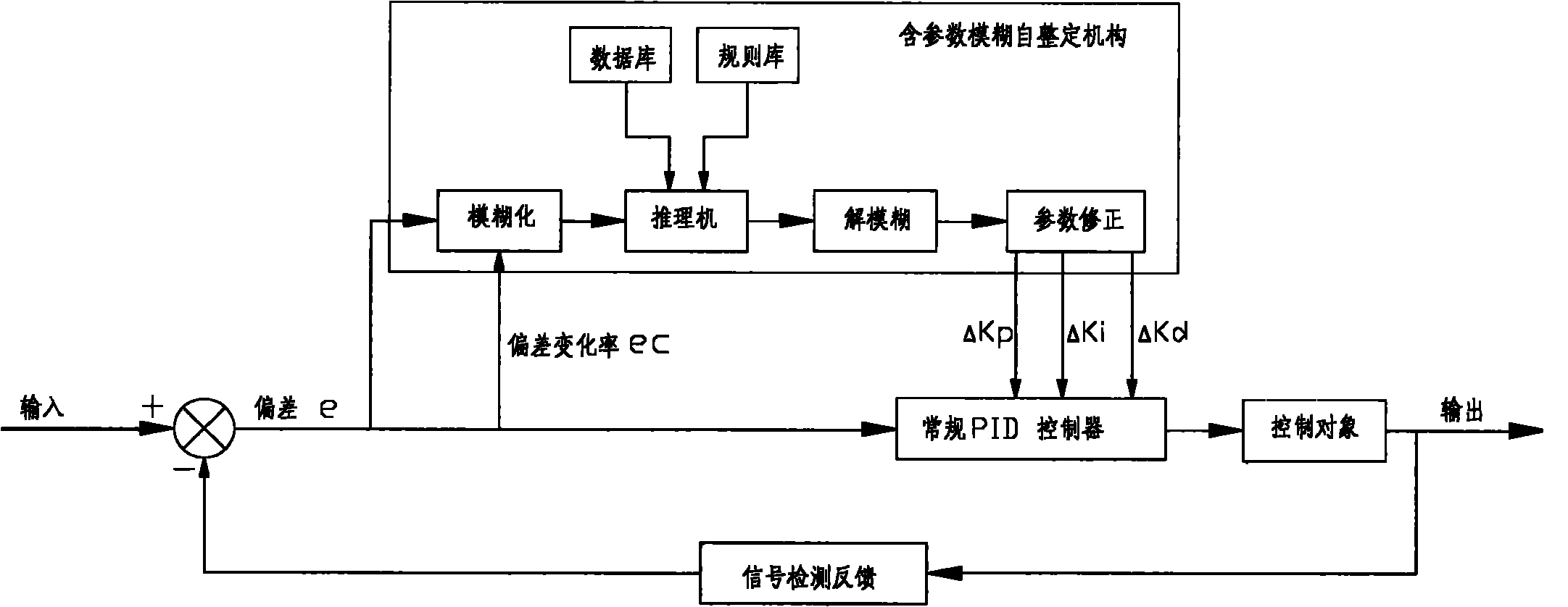

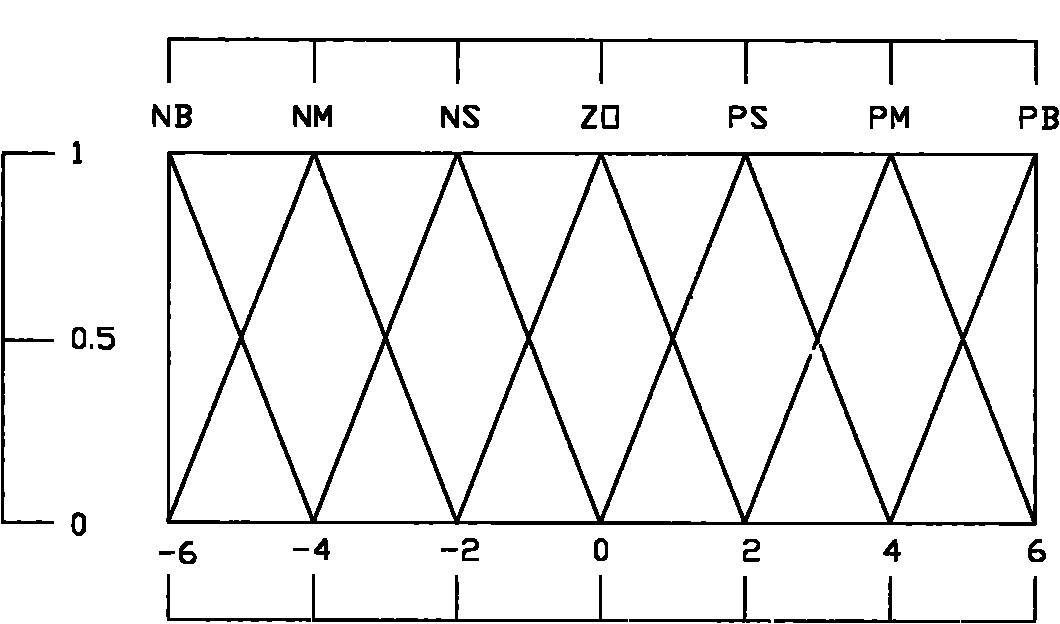

[0029] Such as figure 2 As shown, the fuzzy PID control method for high-precision air conditioners in industrial environments is as follows: the input of the fuzzy PID controller is selected as the deviation e between the expected value and the actual output and the deviation change rate ec (E and EC are respectively e and ec after the input Quantified linguistic variables), establish the binary continuous functional relationship between the parameters Kp, Ki, Kd, the absolute value of the deviation and the absolute value of the deviation change, and the output is the correction amount of the PID parameter ΔKp, ΔKi, ΔKd; determine the three parameters of the PID The fuzzy relationship between the deviation e and the deviation change rate ec, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com