Tea making robot

A robot and mechanical arm technology, applied in the field of automatic tea making equipment, can solve the problems of high torque requirements, high price and few functions of the drive motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

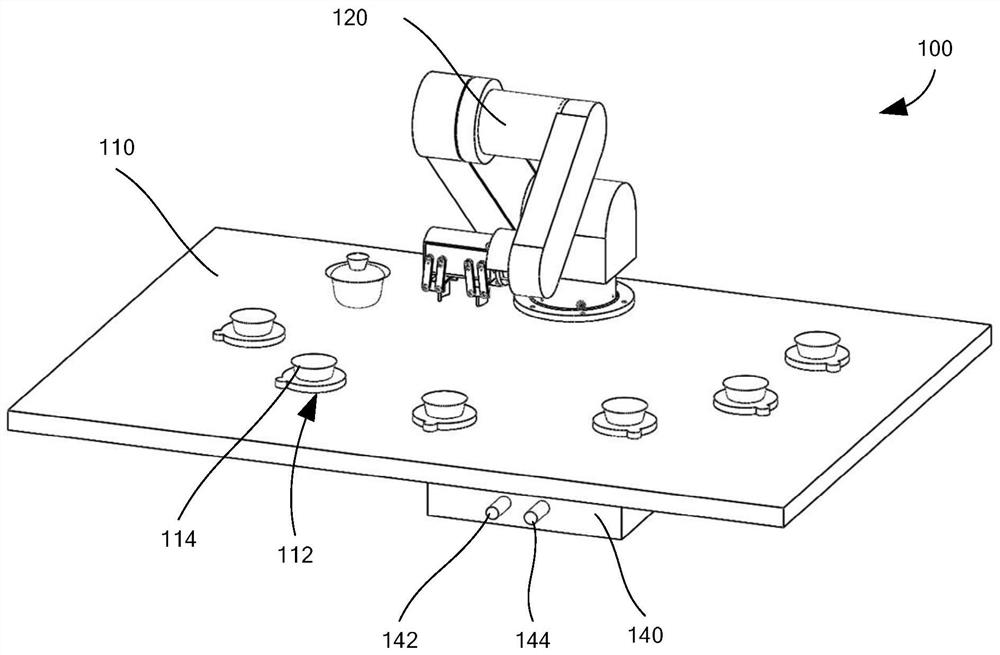

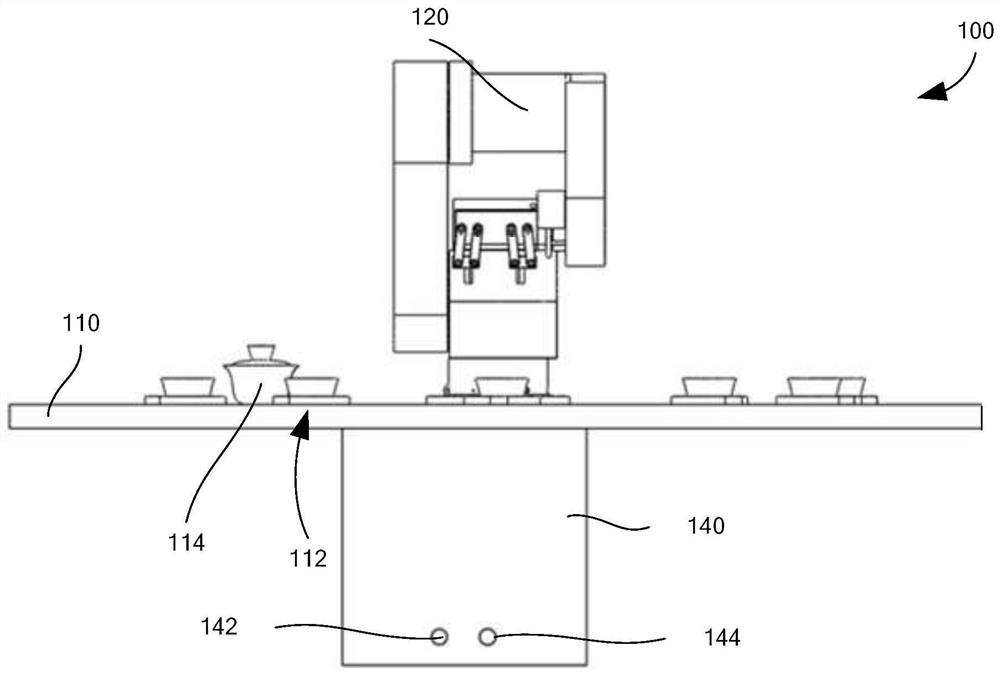

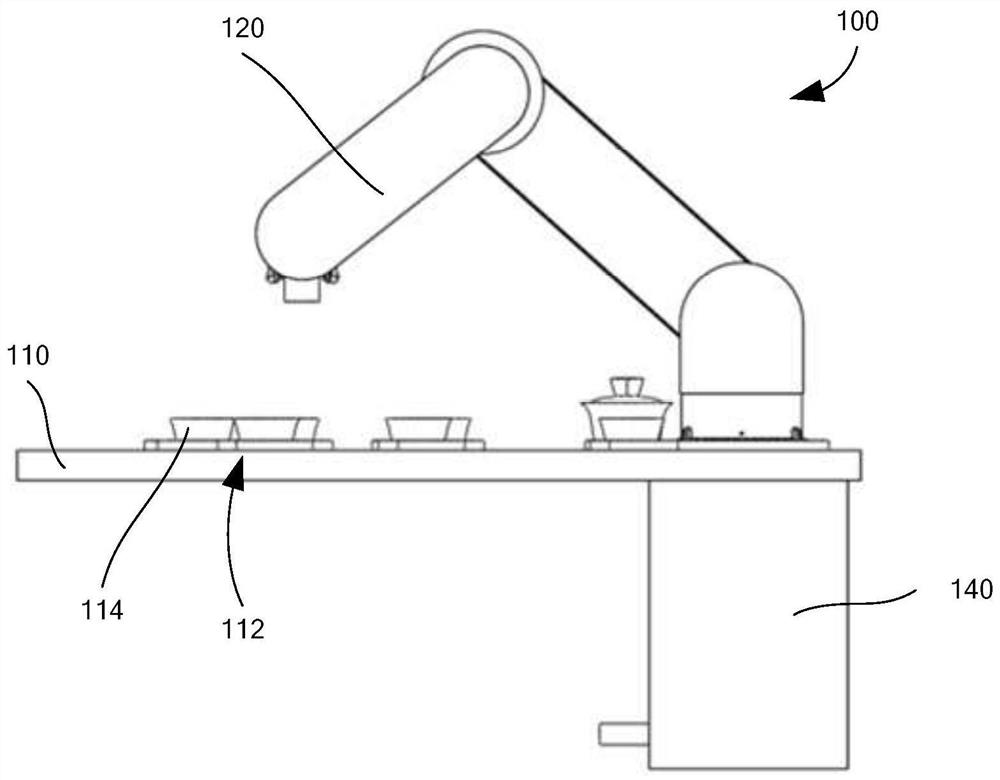

[0051] Such as Figure 1 to Figure 3 As shown, according to the first aspect of the present invention, the present invention provides a tea making robot 100, comprising: a carrier 110; a mechanical arm 120, which is arranged on the carrier 110, and the mechanical arm 120 includes a plurality of rotatably connected Drive shaft; the main control box 140 is connected with the carrier 110, and the main control box 140 is provided with a motor assembly 146 for driving the mechanical arm 120; a transmission assembly is connected to the drive shaft of the motor assembly 146 and the mechanical arm 120 to drive the mechanical arm 120 drive shaft.

[0052]The tea making robot 100 provided by the present invention includes a carrier 110, a mechanical arm 120, a main control box 140 and a transmission assembly, wherein the mechanical arm 120 is arranged on the carrier 110 and includes a plurality of rotatably connected drive shafts, and the main control box 140 is connected with the carr...

Embodiment 2

[0054] On the basis of the first embodiment above, further, as Figure 4 , Figure 7 , Figure 8 with Figure 9 As shown, the transmission assembly includes a plurality of nested transmission shaft assemblies 150 and transmission belts. The nested transmission shaft assembly 150 is arranged in the drive shaft and is located at the connection of two adjacent drive shafts. A nested propeller shaft assembly 150 is arranged at the connection of two drive shafts, so that multiple torques can be transmitted at the connection of two adjacent drive shafts in the same group, without the need to arrange a motor assembly 146 in each drive shaft, which is beneficial A centralized arrangement of the motor assembly 146 is realized. Further, the transmission belt connects the nested transmission shaft 152 and the motor assembly 146, so that when the motor assembly 146 rotates, the nested transmission shaft assembly 150 can be rotated through the transmission belt, thereby driving the driv...

Embodiment 3

[0058] In a specific embodiment of the present invention, further, as figure 1 , figure 2 , image 3 , Figure 5 with Image 6 As shown, the mechanical arm 120 includes a first drive shaft 121, a second drive shaft 122, a third drive shaft 123, a fourth drive shaft 124 and a fifth drive shaft 125 connected in sequence, wherein the first drive shaft 121 is connected to the carrier 110, that is, the plurality of drive shafts of the mechanical arm 120 are sequentially from the end close to the carrier 110 to the end far away from the carrier 110 as the first drive shaft 121 to the fifth drive shaft 125, the first drive shaft 121 and the carrier The connection of the tool 110 forms a first joint 126, the first drive shaft 121 can rotate relative to the carrier 110, the connection of the first drive shaft 121 and the second drive shaft 122 forms a second joint 127, when the second joint 127 rotates It can drive the second drive shaft 122 to move, and the connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com