Servo pressure spot welding system

A technology of spot welding and welding tongs, which is applied in the field of servo pressurized spot welding system, can solve the problems that the welding pressure cannot change with the welding process, increase the cost of servo pressurization, etc., and achieve process upgrades, improve welding quality, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

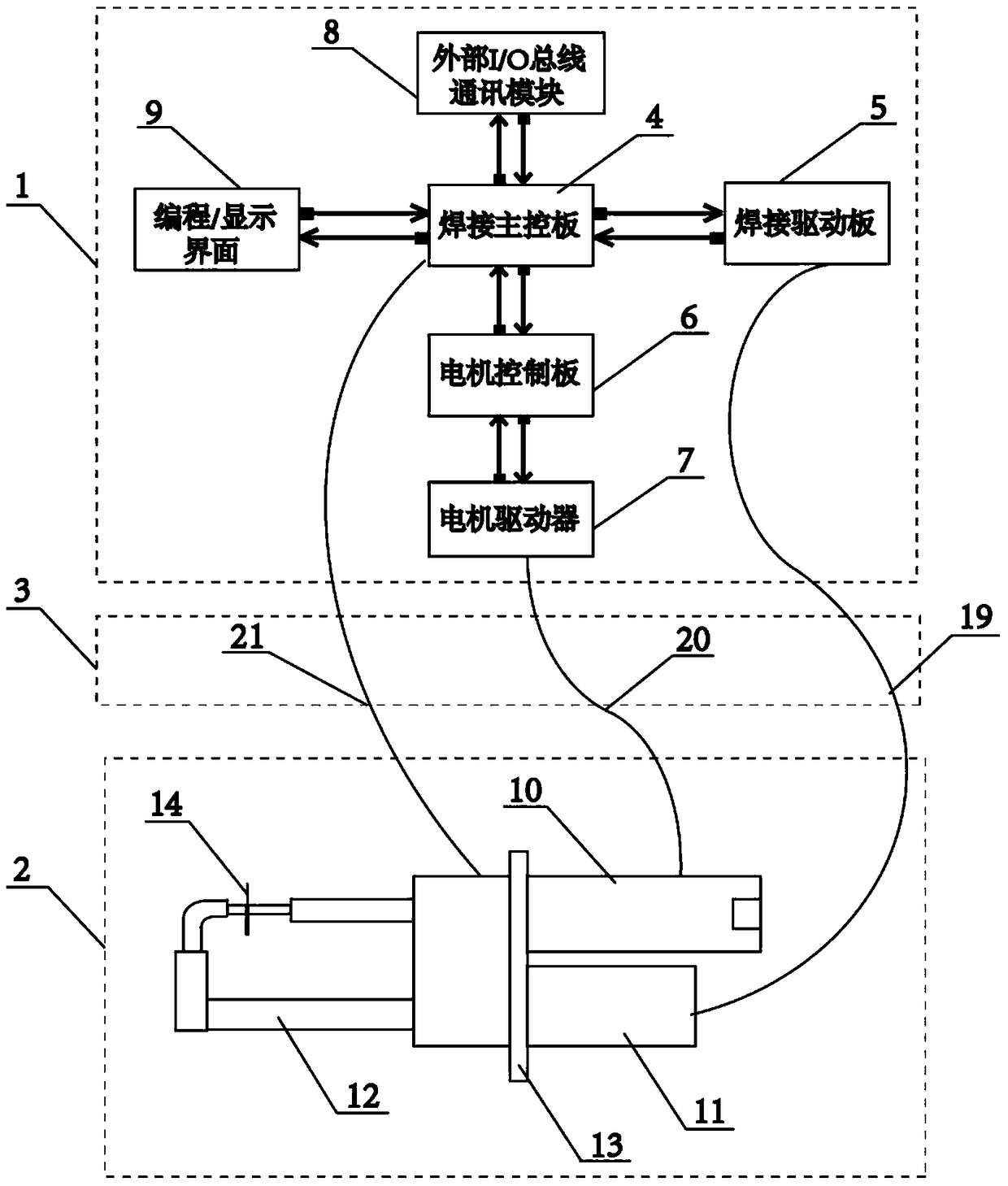

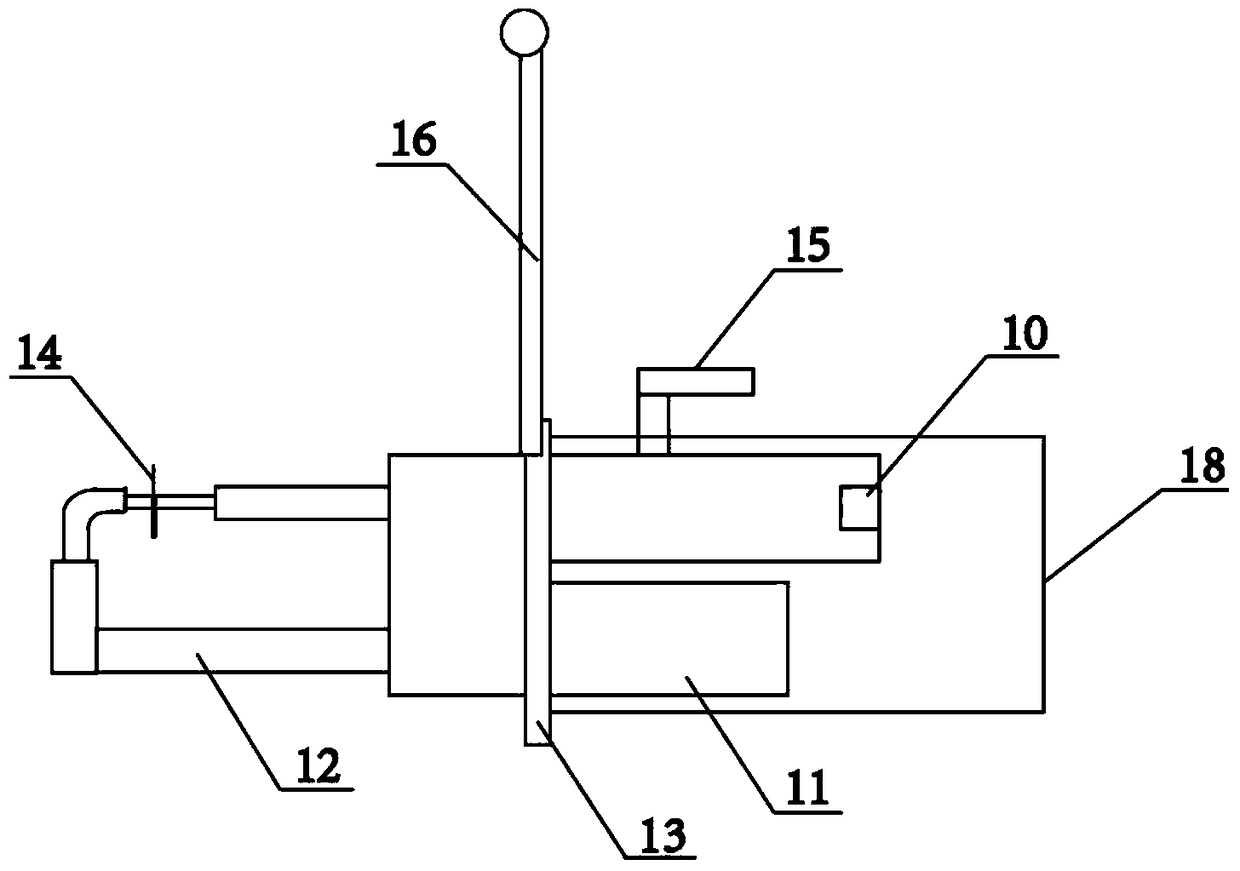

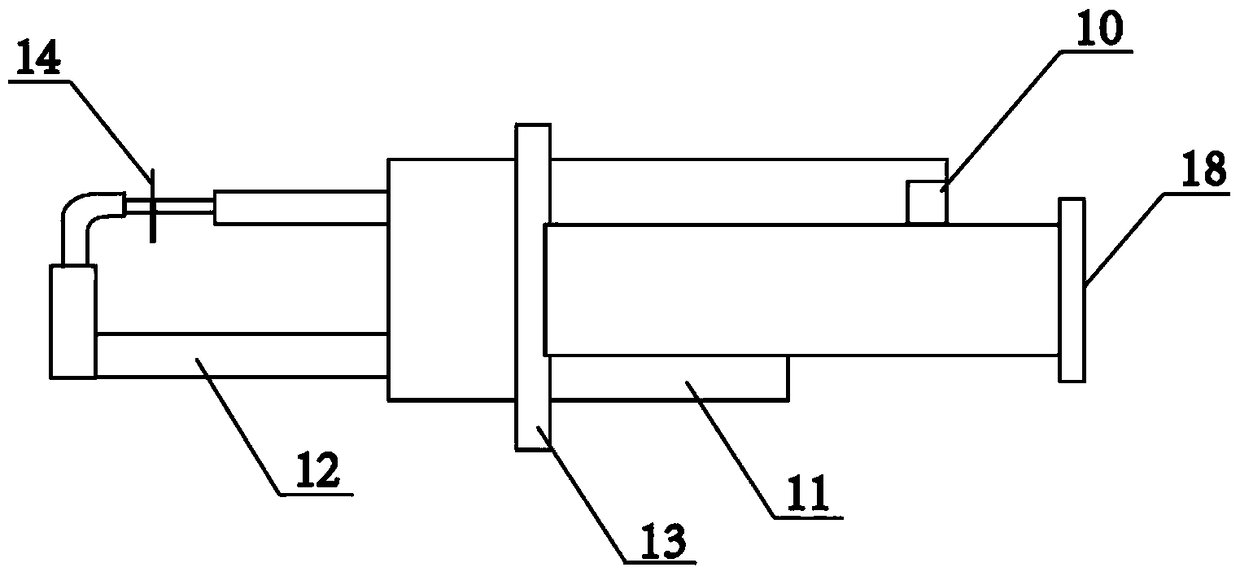

[0032] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, a servo pressurized spot welding system is characterized in that it includes a welding controller 1, a welding tongs 2 and a connecting cable 3, the welding controller 1 is connected to the welding tongs 2 through the connecting cable 3, and the welding control The device 1 includes a welding main control board 4, a welding driver board 5, a motor control board 6, a motor driver 7, an external I / O bus communication module 8 and a programming / display interface 9, and the welding tongs 2 includes a servo motor 10 and a transformer 11 , the electrode arm 12 and the welding tongs body 13, the connecting cable 3 includes a welding power line 19, a motor signal / power line 20, and a welding machine control line 21.

[0034] The main control board 4 of the welding machine takes the single-chip microcompu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com