Positioning centering system and method for true three-axis Hopkinson pressure bar and positioning method

A Hopkinson pressure bar and true three-axis technology, which is applied in the field of precise positioning and centering device of the true three-axis dynamic and static combined loading Hopkinson bar, which can solve the problem of unreliable test results, eccentricity of the pressure bar and test sample, and inconsistency. It is beneficial to ensure the test accuracy and the repeatability of the results, and achieve the effect of reliable, fast centering and alignment of the test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

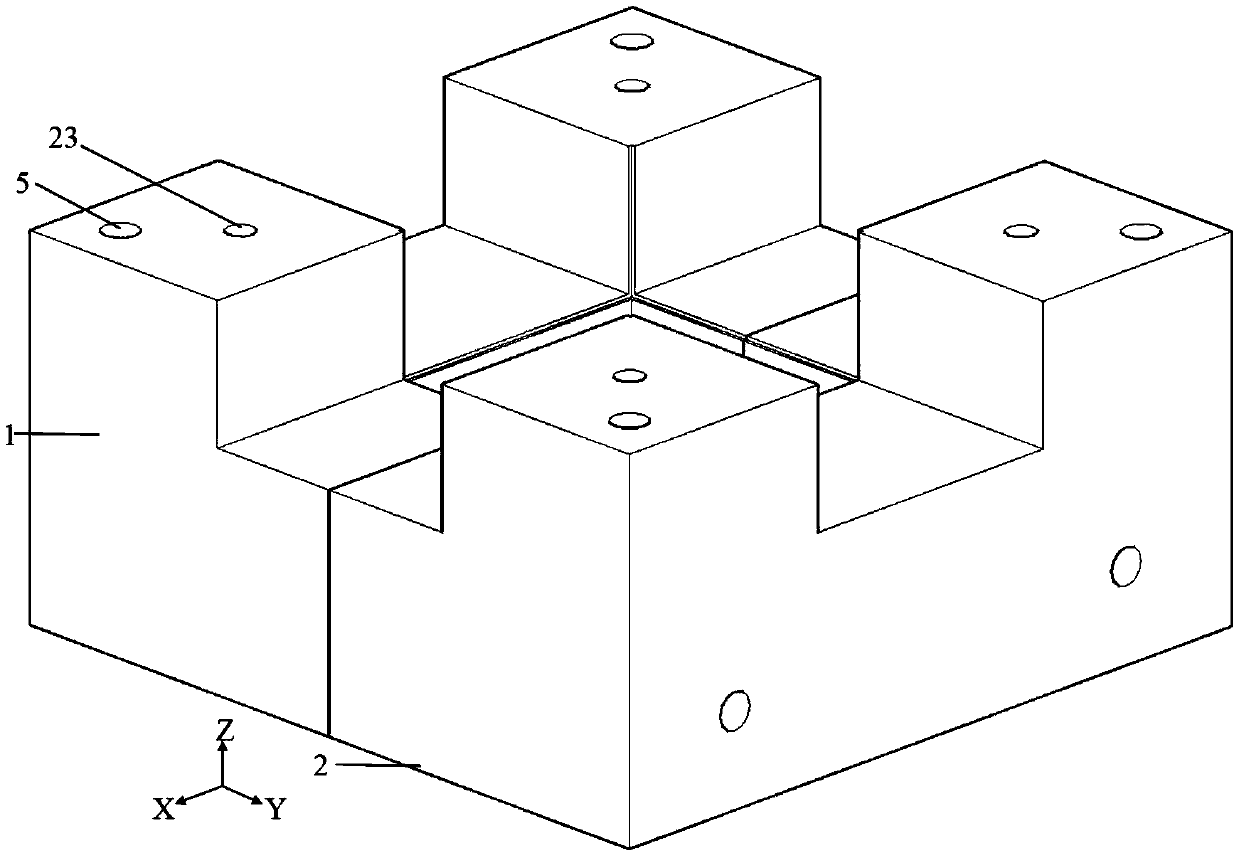

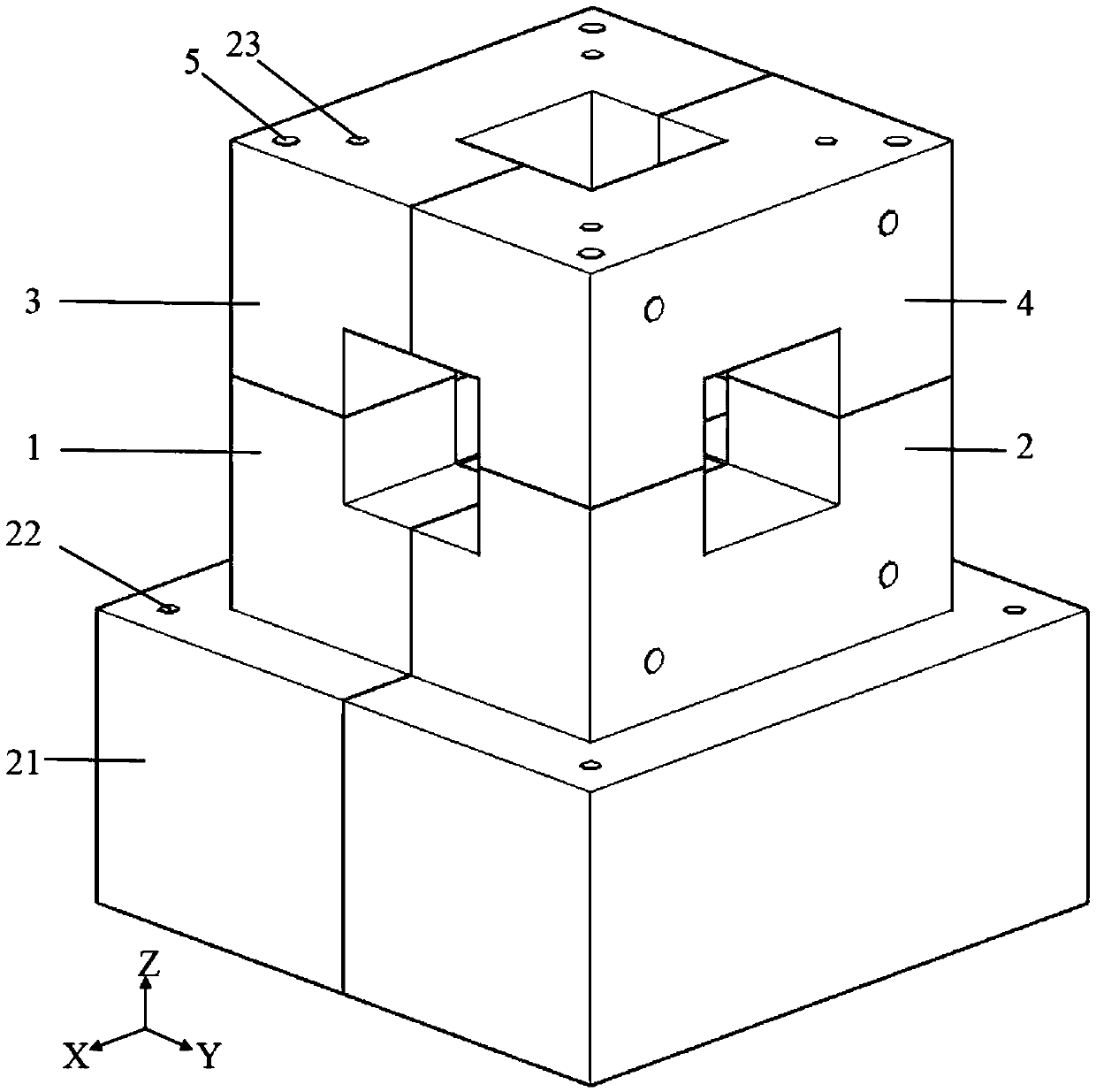

[0026] The precise positioning and centering device of the true three-axis dynamic and static combined loading Hopkinson bar is the core of the three-axis six-way synchronous coordinated control electromagnetic loading Hopkinson bar system. The precise positioning and centering device includes a positioning guide centering box and an infrared laser alignment system. A round hole and a square hole are reserved on the side of the positioning guide centering box. The size of the hole above the six sides is consistent with the size of the square rod. The square rod passes through the square hole and contacts the cube sample; the size of the round hole is consistent with the size of the screw. It is used to combine the detachable positioning guide centering box into an integral structure and to quickly and accurately place the positioning guide centering box at the exact ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com