Lid lock apparatus for vehicle

A vehicle and cover lock technology, which is applied in vehicle locks, electric vehicle locks, electric locks, etc., can solve the problems of increasing the number of parts of the cover lock device, increasing assembly hours, and disengaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

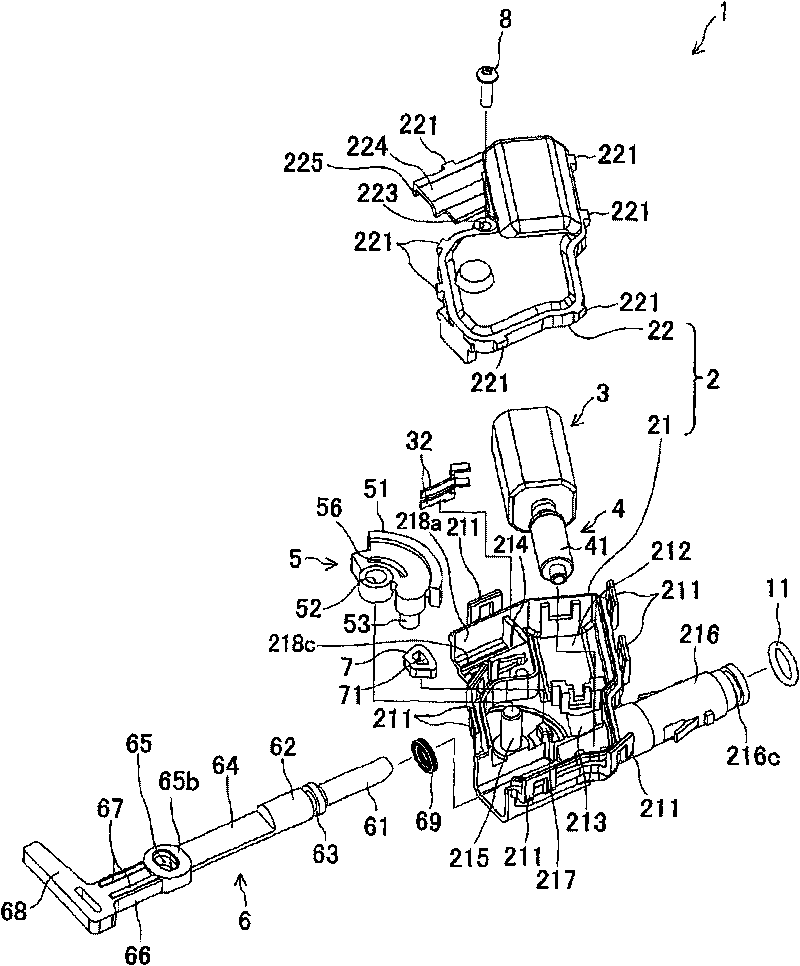

Image

Examples

Embodiment approach

[0053] The present invention is not limited to the above-mentioned embodiments, and may be deformed or expanded as follows.

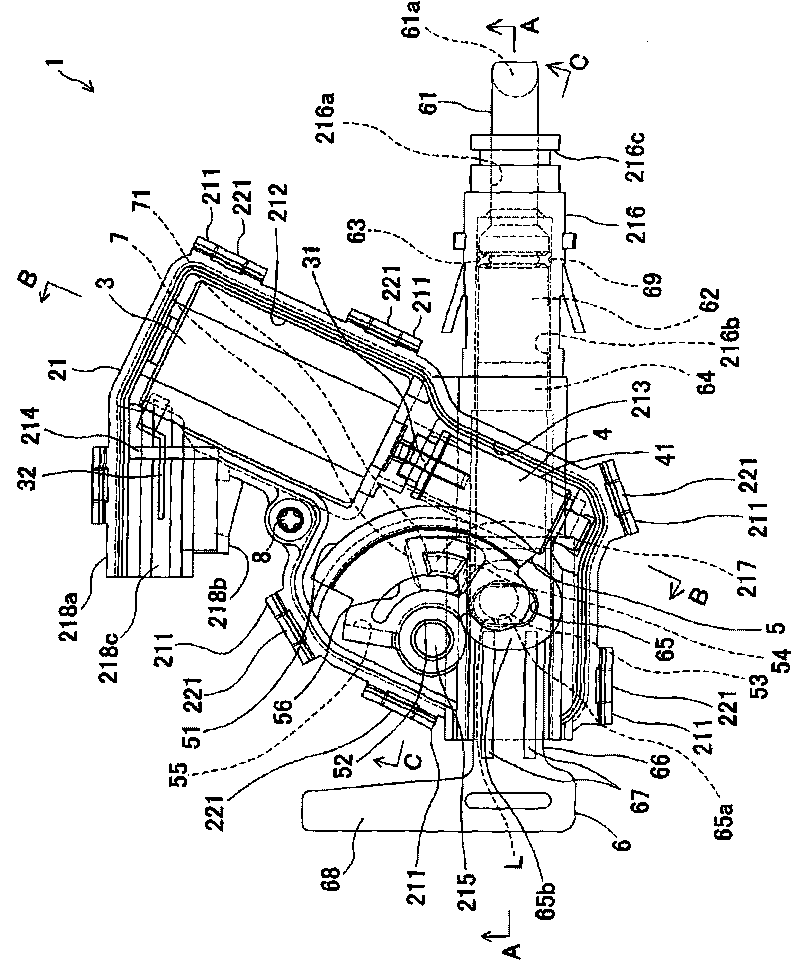

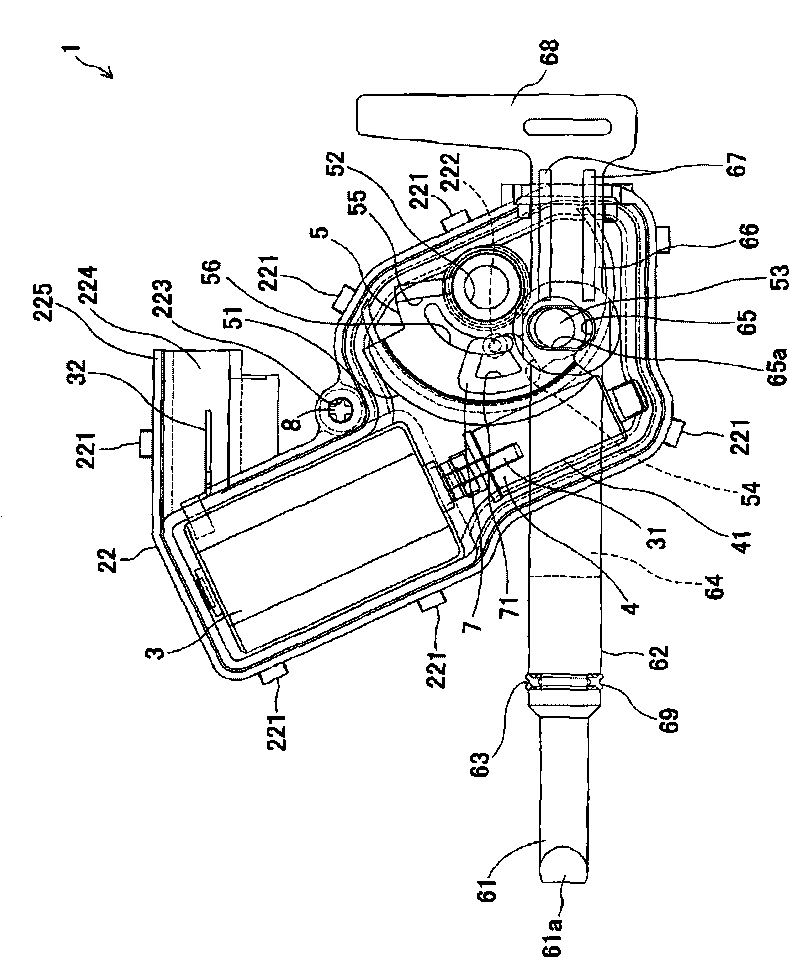

[0054] In the above-mentioned embodiment, in order to prevent the inclination when the lock portion 61 protrudes from the case 2, the guide center P is set at the center in the thickness direction of the support portion 62 of the lock shaft 6. However, in order to prevent the lock portion 61 from The inclination when stored in the housing 2 can also be set at the center of the thickness direction of the flat plate portion 66 sandwiched by the housing 2, and the guide center P set at the center of the thickness direction of the flat plate portion 66. In the vicinity of the center P, the inner peripheral surface of the interlocking hole 65 protrudes radially inward.

[0055] Or, considering the guiding parts of the locking part 61, the sealing ring 69 and the flat plate part 66 which are guided by the housing 2, the guiding center P can also be set at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com