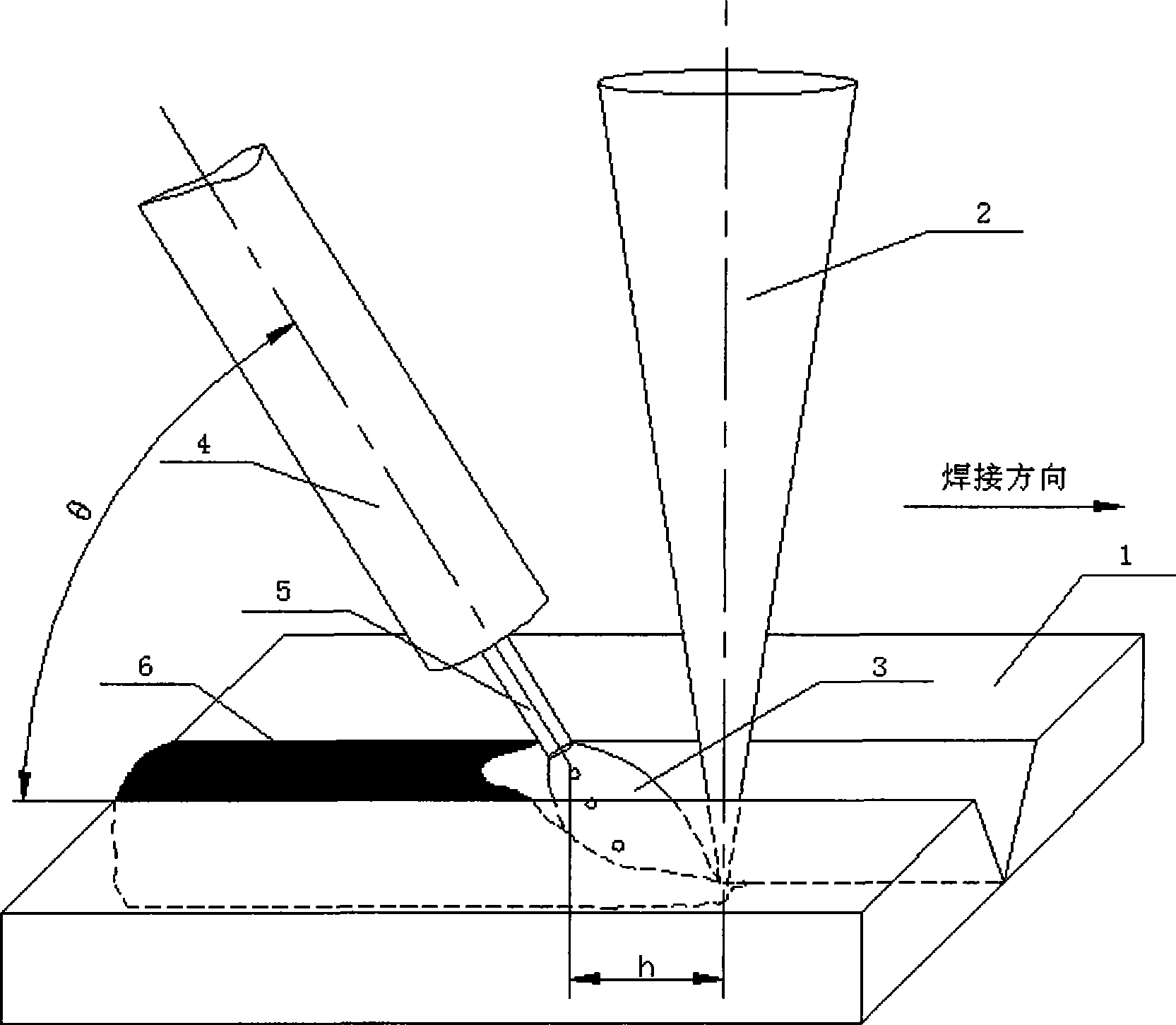

High-strength or ultra-high strong steel laser-electrical arc composite heat source welding method

A composite heat source, ultra-high-strength steel technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complex welding process, difficult welding work, and deterioration of workers' operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The laser used in the test is the HL2006D Nd:YAG solid-state laser produced by the German HAAS company, with a maximum output power of 2.6kW and a continuous wave laser with an output wavelength of 1.06μm, and a focusing lens with a focal length of 200mm; the arc welding machine is produced by the Austrian Fonius company TPS5000 digital GMA welding power supply and wire feeder; the HS-80 low-alloy high-strength steel welding wire with a diameter of 1.2 (strength grade 80kg) developed by the Harbin Welding Research Institute is selected; the high-strength steel base materials used in the test are 12mm thick JFE980S low-alloy high-strength steel (tensile strength 980MPa), 25mm thick HG980 low-alloy high-strength steel (tensile strength 980MPa) and 25mm thick 35CrMnSiA ultra-high-strength steel (tensile strength 1700MPa).

[0021] The test is divided into inclined Y-groove welding crack test and butt joint performance test. The oblique Y-groove welding crack test is carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com