Intersecting line dual-annular seam automatic welding machine

An automatic welding machine and intersecting line technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of good welding quality, complicated process, expensive cost, etc., to improve efficiency, simplify welding process, and protect safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

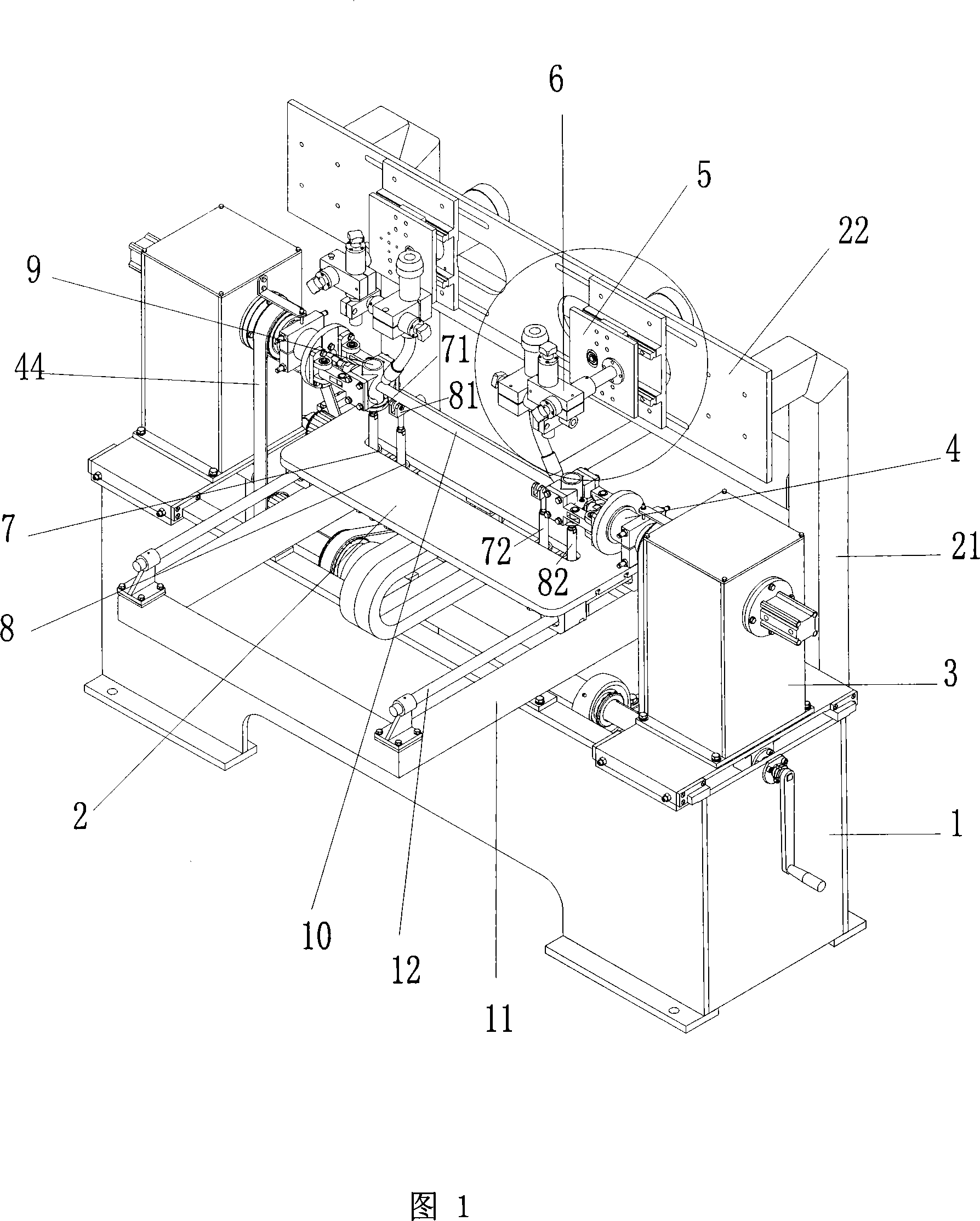

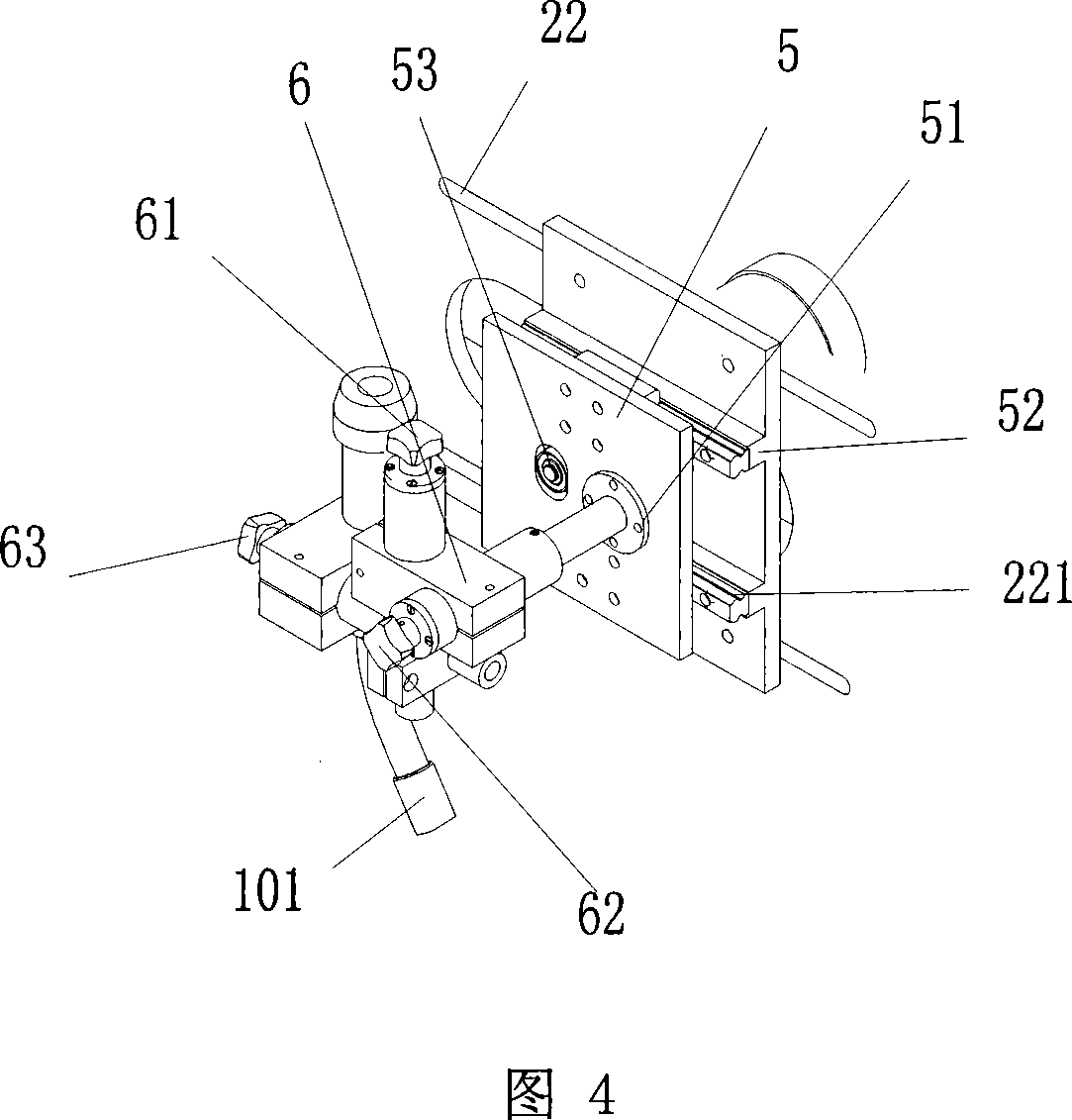

[0028] As shown in Fig. 1, a kind of intersecting line double circular seam automatic welding machine comprises bed assembly 1, and bed assembly 1 is saddle shape, and power device is installed in bed assembly 1, and in addition, on both sides of bed assembly 1 A fixture box 3 is respectively installed, and a set of rotary fixture 4 is respectively installed on each fixture box 3, and the rotary fixture 4 is driven by a power unit. Two columns 21 are installed on the rear side of the bed assembly 1 , and an eccentric slider mechanism mounting plate 22 is installed between the two columns 21 . Two sets of eccentric slider mechanisms 5 are installed on the eccentric slider mechanism mounting plate 22 , and each set of eccentric slider mechanisms 5 is respectively equipped with a set of welding torch assemblies 6 .

[0029] A guide column bracket 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com