Swing arc-based multi-layer and multi-channel weld tracking system and identification method thereof

A technology of multi-layer multi-pass welding and tracking system, which is applied in the field of multi-layer multi-pass welding seam tracking system and identification field, can solve the problem that it is difficult to realize automatic tracking of thick plate multi-pass multi-pass welding seam, etc. The effect of easy implementation, stable and reliable operation, and improved accuracy

Inactive Publication Date: 2012-08-01

XIANGTAN UNIV

View PDF4 Cites 58 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The first purpose of the present invention is to provide a multi-layer multi-pass welding seam tracking system based on swinging ar

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

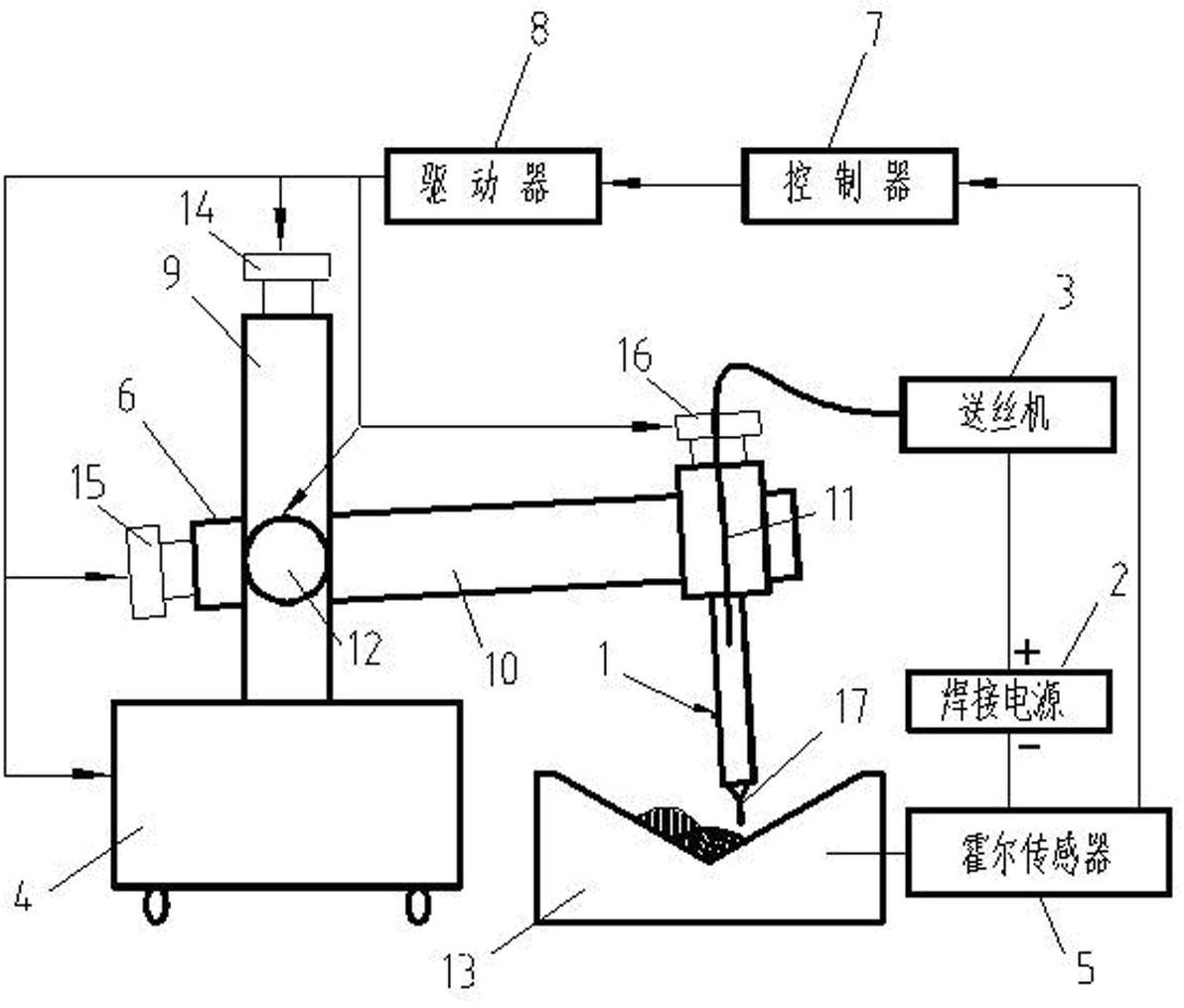

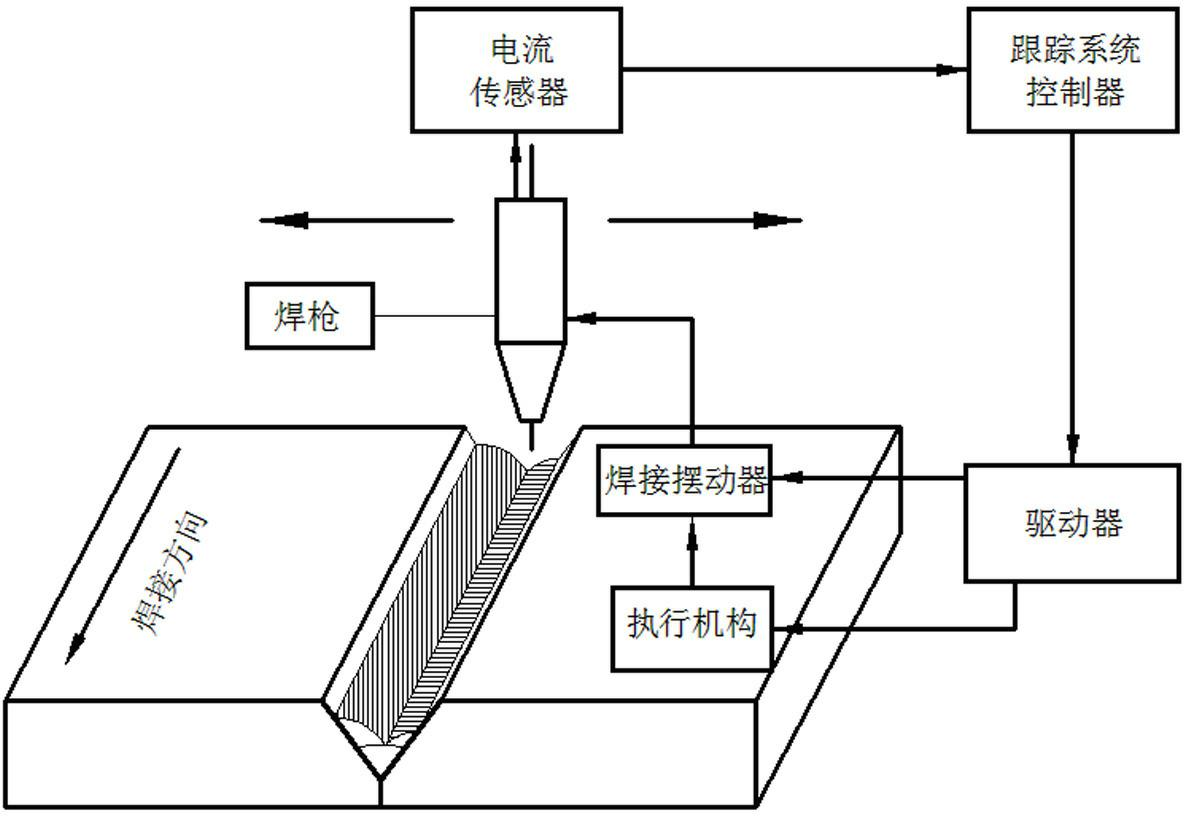

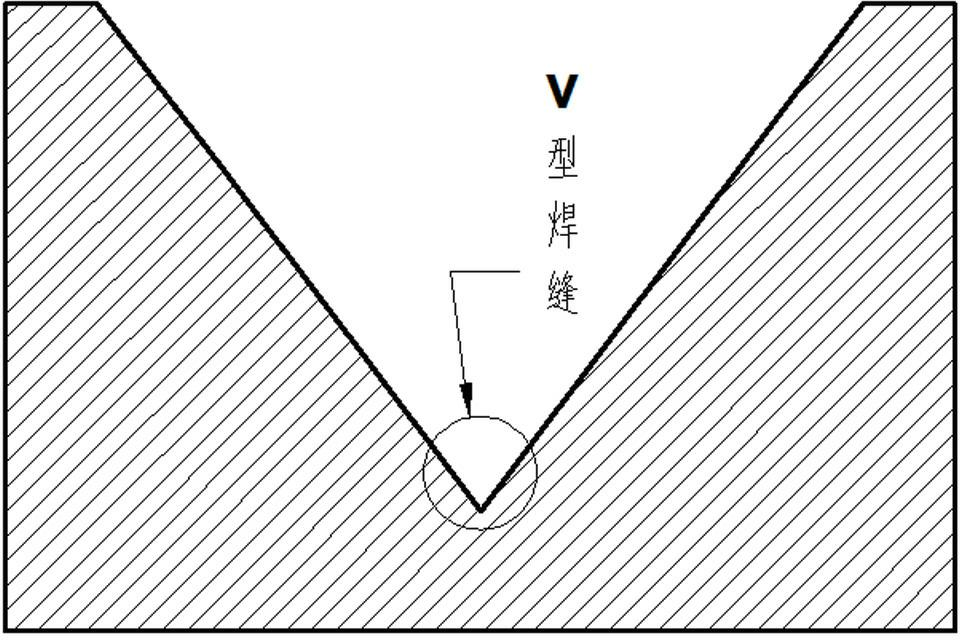

The invention discloses a swing arc-based multi-layer and multi-channel weld tracking system and an identification method thereof. The weld tracking system comprises a welding gun, a welding power supply, a wire feeder, a welding tractor, a swinger, a driver, a hall current sensor, a main carriage and the like, wherein the welding gun is used for performing oscillatory scanning on a weld groove when driven by the swinger in the welding process, the change of relative positions between the welding gun and a workpiece directly causes the change of arc length, and the change of the arc length causes the change of arc parameters such as arc current, arc voltage and the like; the hall current sensor is used for sending detected welding current signals and positioning pulse signals to the controller, automatically judging the weld shape according to certain operation rules, processing the weld shape by selecting corresponding weld deviation signal extraction schemes and acquiring weld deviation information; and the swinger is used for regulating weld deviation, automatically tracking welds and completing automatic welding.

Description

technical field [0001] The invention belongs to the technical field of automatic welding control, and in particular relates to a tracking system and identification method for multi-layer and multi-pass welding seams based on swinging arcs. Background technique [0002] Seam tracking technology is an important research direction to realize welding automation. For the groove welding of thick plates, due to the influence of groove processing and assembly size and position errors, the use of accurate seam tracking technology for multi-layer and multi-pass welding is the key to ensure the welding quality. [0003] The welding seam tracking technology based on arc sensor and visual sensor is the mainstream of research and application at present. It can achieve a good tracking effect in the welding process of workpieces with single-layer weld seams. For multi-layer multi-pass welding of thick plates, in After the first seam is welded, the form of the welded joint has often changed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/127B23K9/022

Inventor 洪波洪宇翔李湘文阳佳旺杨学道言俊光

Owner XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com