Automatic welding device and welding method for stators

An automatic welding and stator technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of reducing magnetic permeability, low working efficiency of lamination and fixing process, waste of effective magnetic permeability area of silicon steel sheet, etc. Magnetic permeability, avoid human operation welding errors, improve physical properties and the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

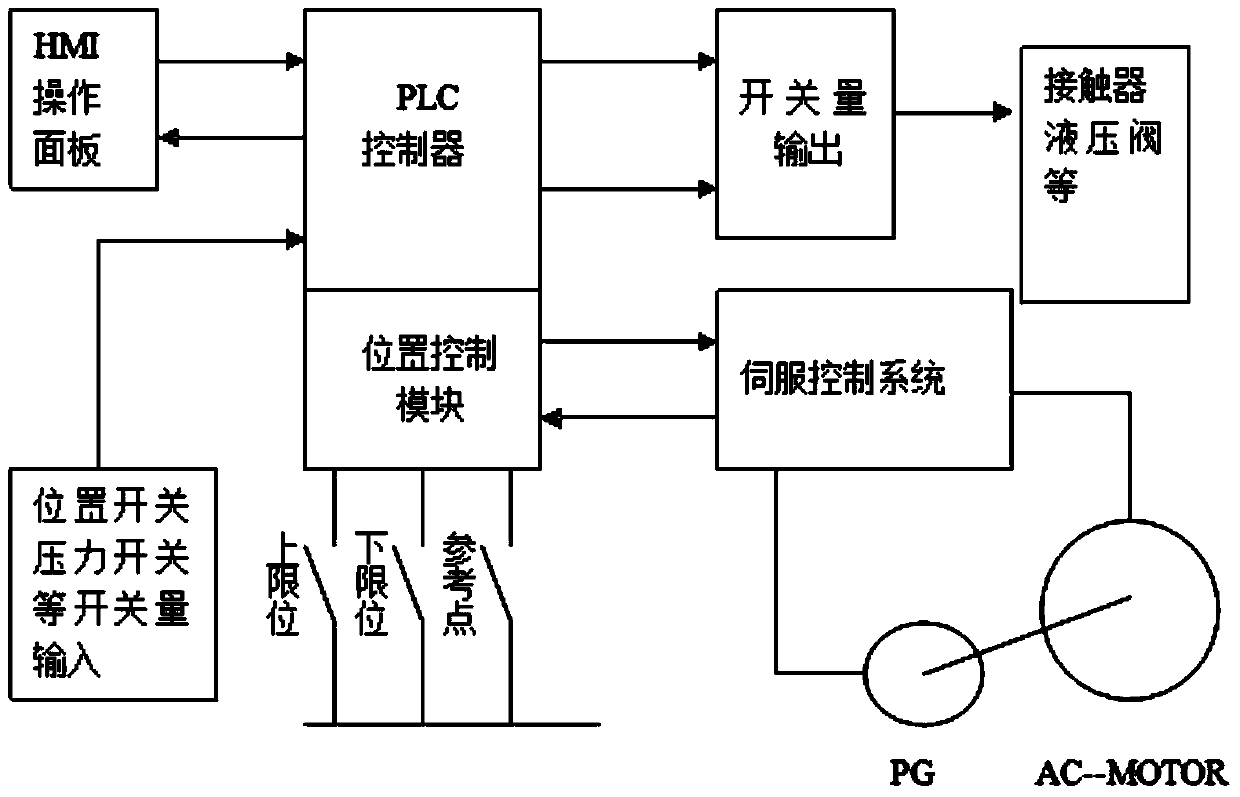

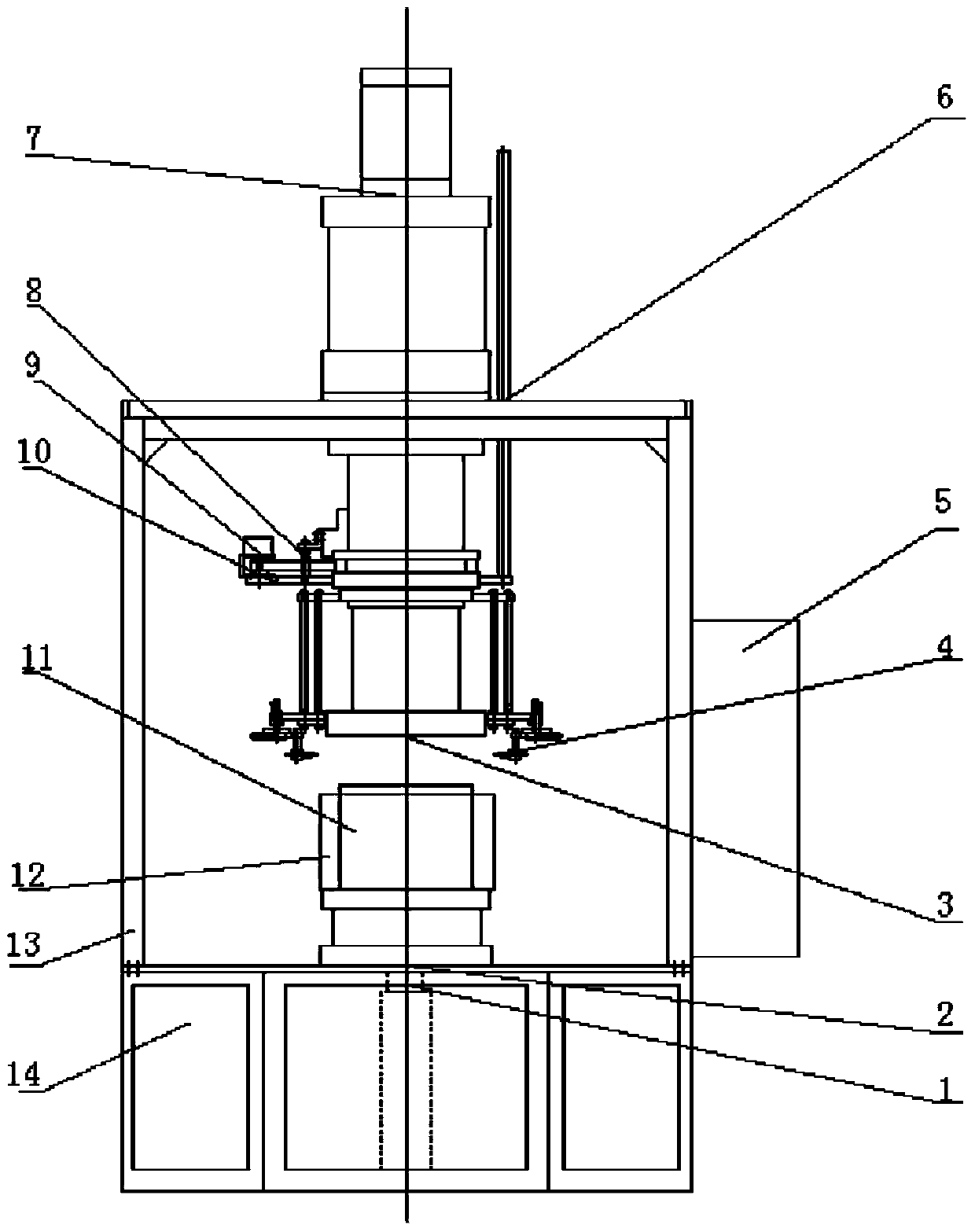

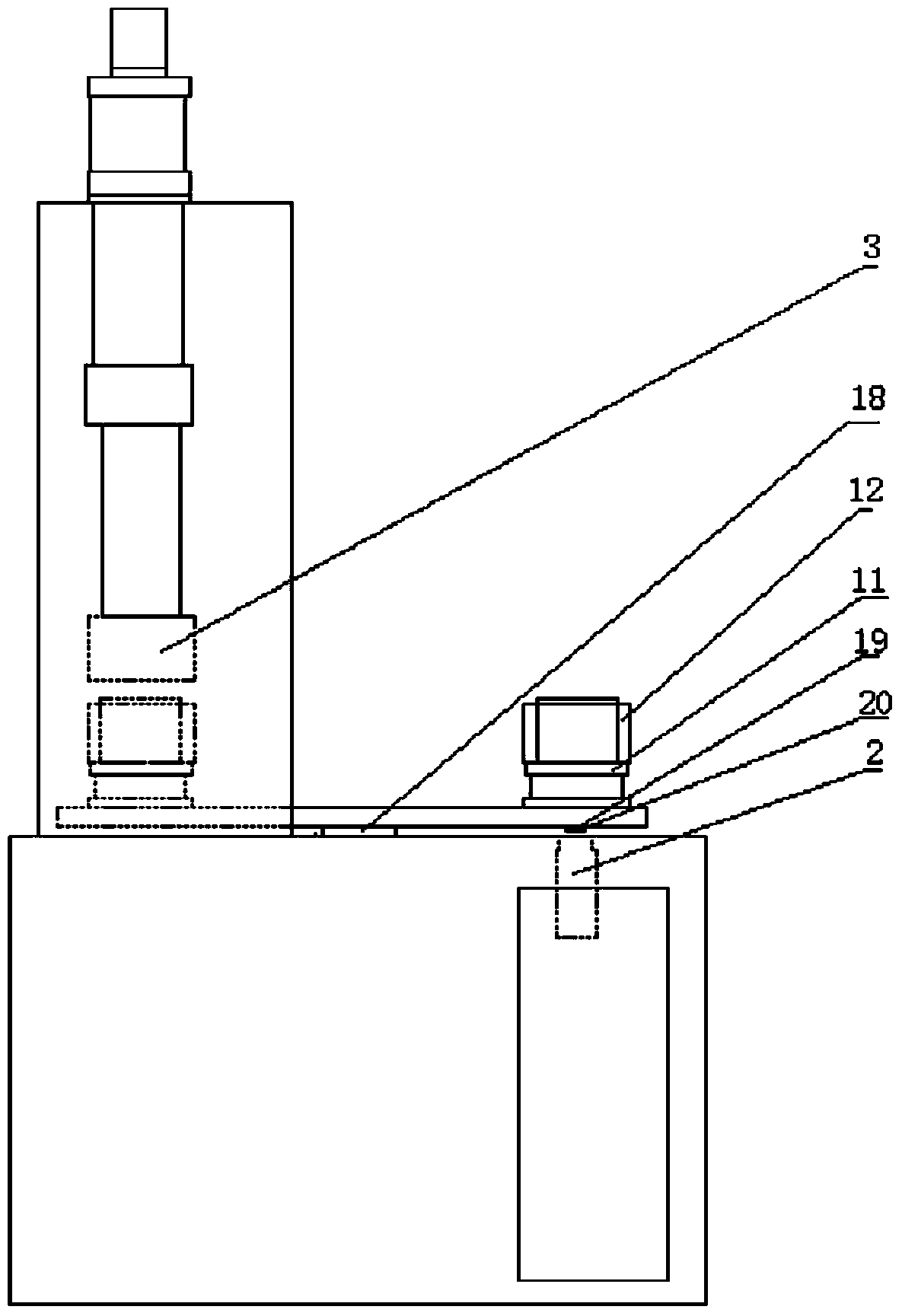

[0032] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-5 As shown, an automatic welding device for a stator includes a housing 13, a base 14, a turntable 1, a lifting mechanism 2, a pressing device 3, a welding torch 4, an electrical cabinet 5, a guide rod 6, a hydraulic cylinder 7, and a screw 8. Servo motor 9, mandrel fixture 11 and servo control system, the housing 13 is installed on the rear side area above the base 14, the turntable 1 is installed on the base 14 through the rotary shaft 18, and the turntable 1 The rotary motion is realized by the rotary shaft 18, the rear semicircle of the rotary table 1 is inside the casing 13 for welding, and the front semicircle of the rotary table 1 is outside the casing 13 for the installation and disassembly of the stator 12 silicon steel sheet; The base 14 is a rectangular box with a hollow interior, and a circular hole is opened on the upper side. The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com