Positioning attachment for a welding torch

a technology of positioning attachment and welding torch, which is applied in the direction of soldering apparatus, manufacturing tools,auxillary welding devices, etc., can solve the problems of poor overall weldments, inexperienced welders often have difficulty establishing the proper torch angle, and uneven welding angl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

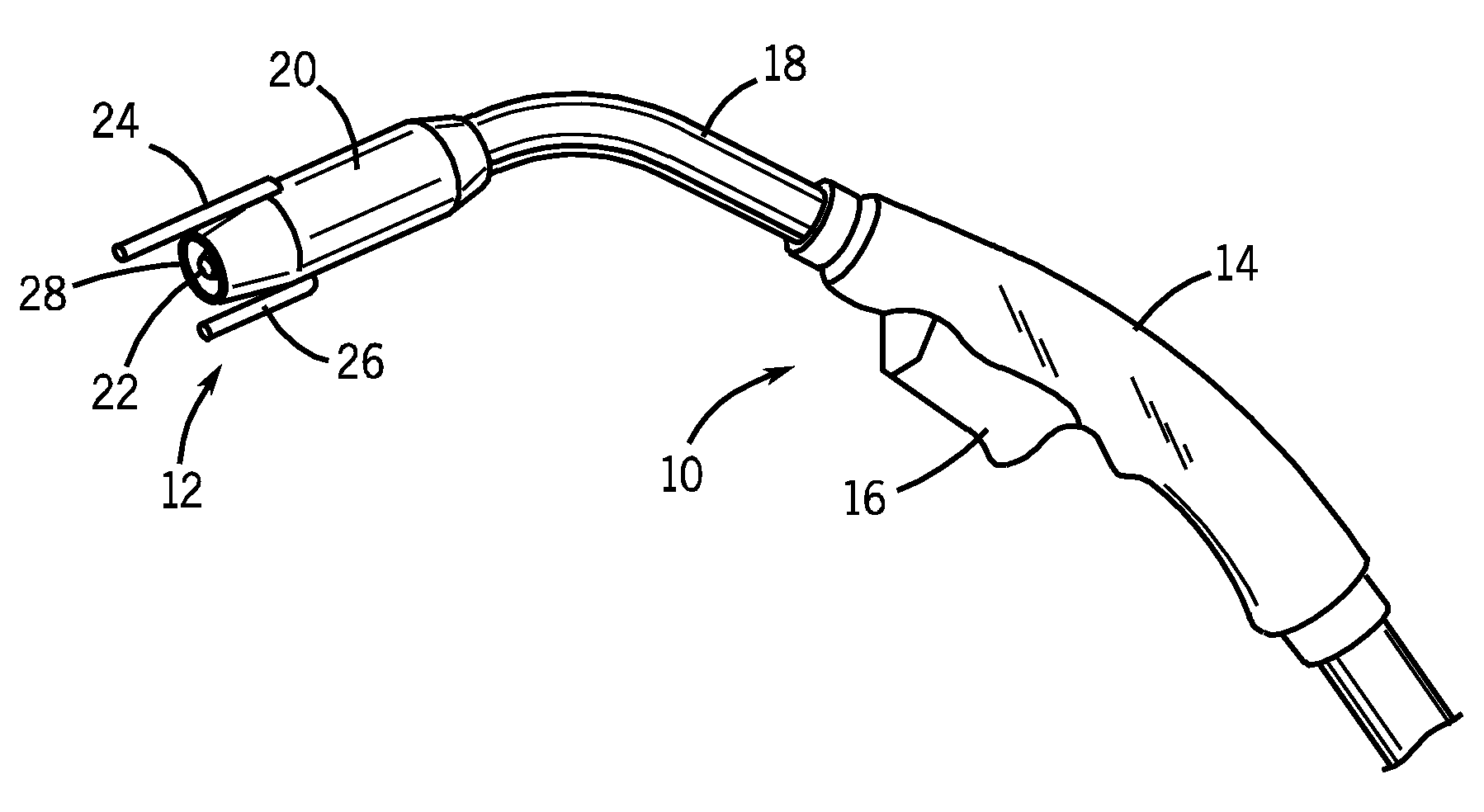

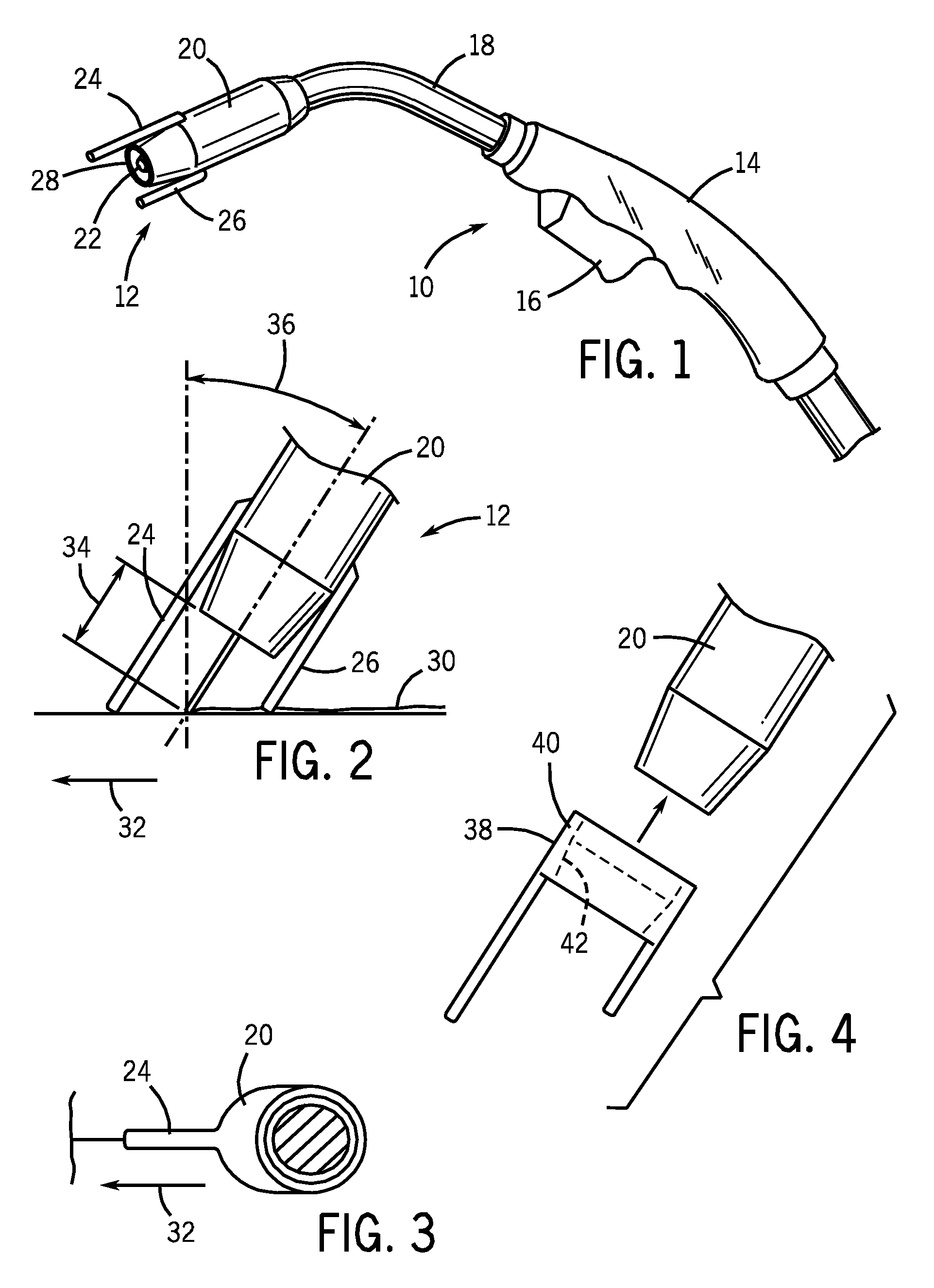

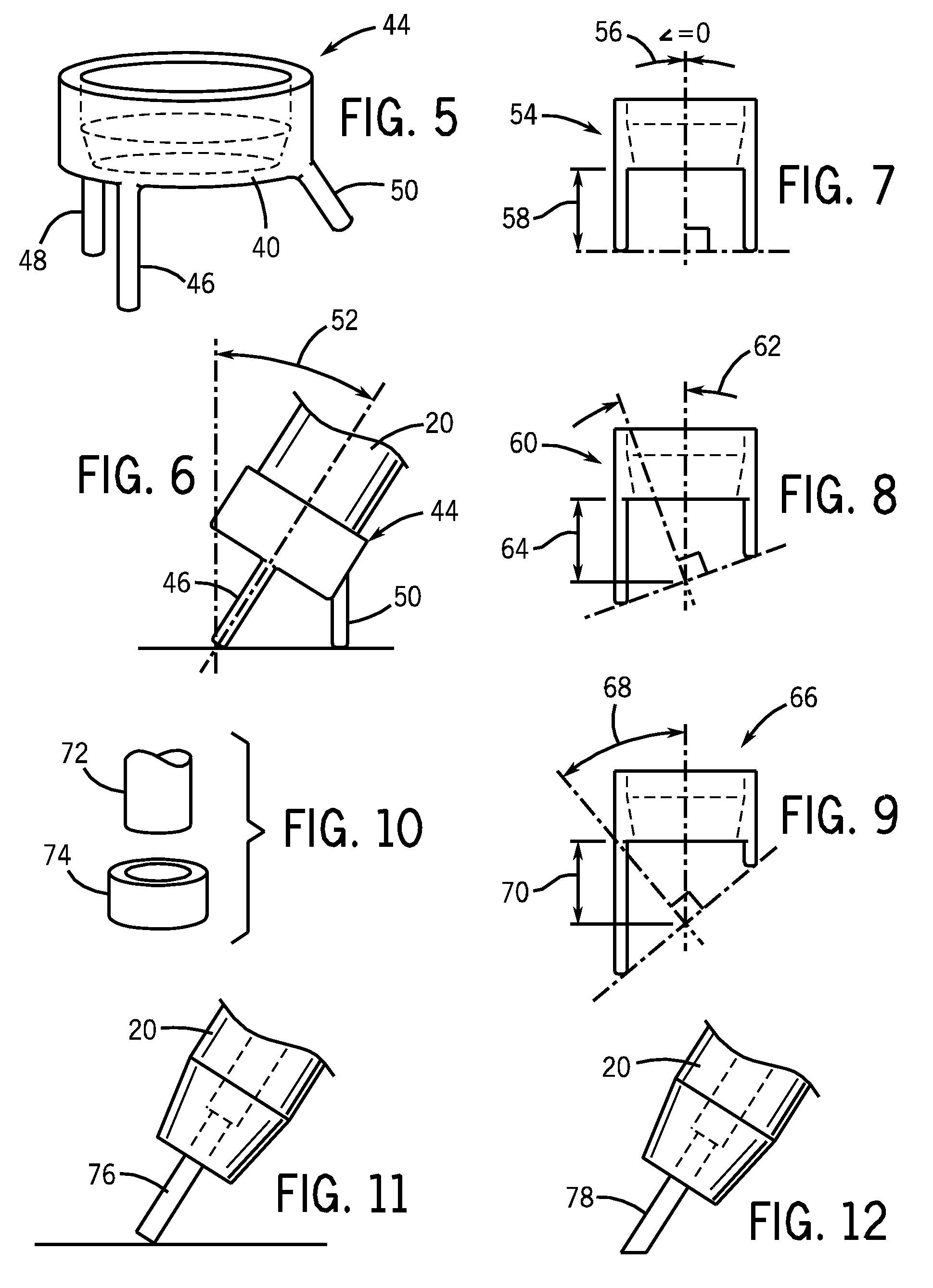

[0021]FIG. 1 illustrates a welding torch 10 that incorporates a positioning attachment 12, which establishes the proper torch angle and / or torch to workpiece height during welding or welding training. The torch 10 has a handle 14 with a trigger 16, which a welder may use to start and stop welding. An extension 18 from the handle 14 is connected to a nozzle 20. A contact tip 22 extends outward from the inner cavity of the nozzle 20. One embodiment of the present invention, which includes two positioning legs 24, 26 permanently attached to the outside of the nozzle on either side of the aperture 28, is shown in FIG. 1. During welding, wire is fed out of the contact tip 22 while gas is fed out of the aperture 28 into the welding area. In certain embodiments, the positioning attachment 12 may be made of a metal, such as brass or steel, which is resistant to the heat generated during welding. In other embodiments, the positioning attachment 12 may be made of ceramic. It should be noted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com