A kind of preparation method of magnesium alloy welding wire

A magnesium alloy and welding wire technology, which is applied in the field of magnesium alloy welding wire preparation, can solve the problems of low drawing efficiency, inability to industrialize magnesium alloy welding wire, and inability to solve extruded wire joint connections, etc., to save energy, reduce time and save money. Cost, the effect of reducing the number of drawing passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

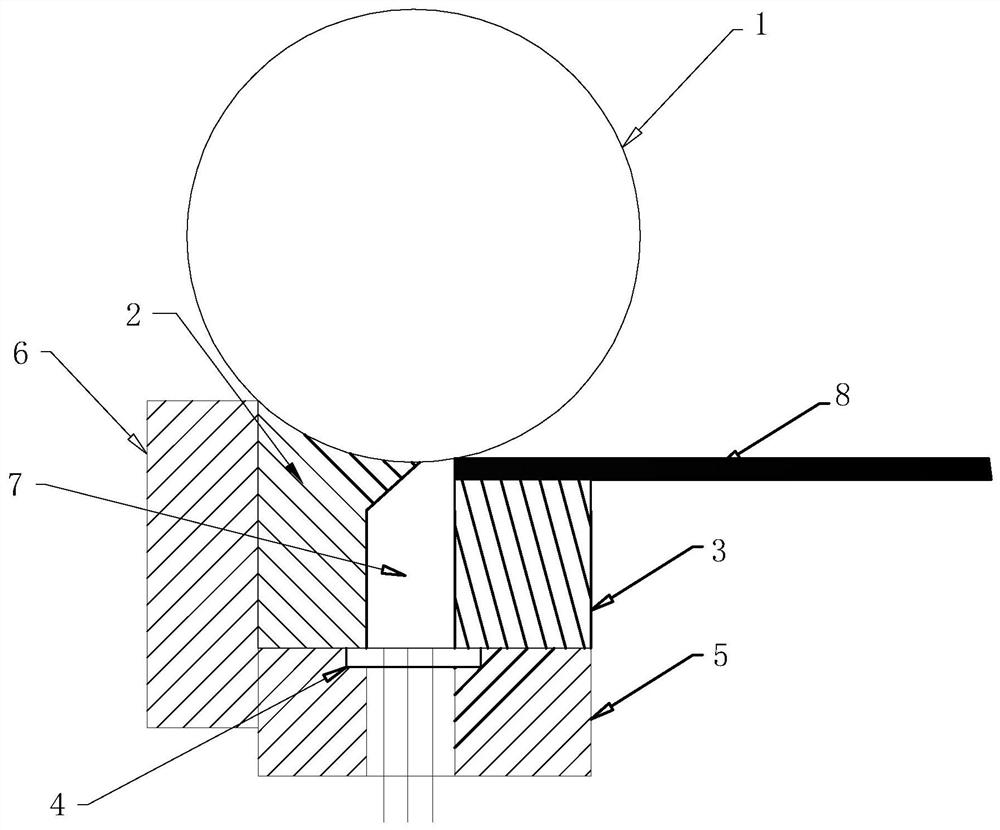

Image

Examples

Embodiment 1

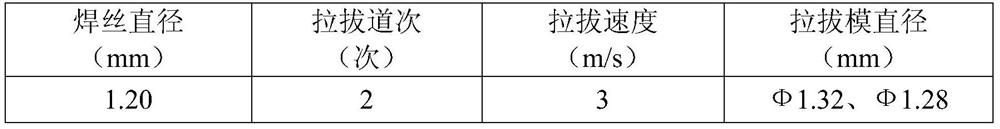

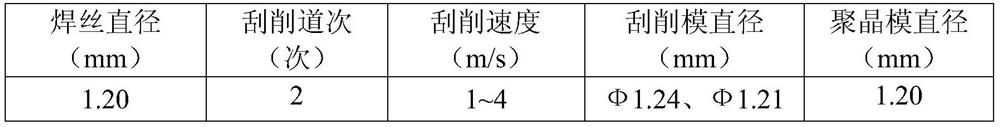

[0024] Prepare Ф1.2mm diameter specification AZ31 magnesium alloy welding wire, the specific preparation is as follows:

[0025] 1. Ingot extrusion: The Ф110mm ingot blank is homogenized and annealed at 450°C / 24h and sawed, the wagon grows 450mm, and the Ф100mm ingot is prepared for extrusion. The extrusion die, the sliding die and the extrusion barrel are heated to 380° C. respectively, and the magnesium alloy bar is heated to 400° C. in advance. The extrusion speed of the first material is 1m / min, the normal extrusion speed is 1.5m / min, and the extrusion ratio is 15. The ingot is extruded into a Ф9.5mm straight rod and wound into a roll.

[0026] 2. Wire billet cleaning: use the wire brush automatic cleaning device to remove the oxide skin on the surface of the Ф9.5mm wire billet, and use acetone to clean the surface oil and dust to ensure that there are no oxides, oil stains and burrs on the surface of the extruded wire billet.

[0027] 3. Preheating: Preheat the pre-extru...

Embodiment 2

[0038] To prepare Mg-Zn-Y-Zr rare earth magnesium alloy welding wire with a diameter of Ф1.6mm, the specific steps are as follows:

[0039]1. Ingot extrusion: The ingot Ф110mm ingot blank is homogenized and annealed at 480°C / 24h and then sawed and turned into 450mm and Ф100mm ingot blanks to prepare for extrusion. The extrusion die, the sliding die and the extrusion barrel are heated to 430° C. respectively in advance, and the magnesium alloy bar is heated to 450° C. at the same time. Extrude the ingot into a Ф9.5mm straight rod with the extrusion speed of the first material 1m / min, the normal extrusion speed 1m / min, and the extrusion ratio of 10, and wind it into a coil.

[0040] 2. Wire billet cleaning: use the wire brush automatic cleaning device to remove the oxide skin on the surface of the Ф9.5mm wire billet, and use acetone to clean the surface oil and dust to ensure that there are no oxides, oil stains and burrs on the surface of the extruded wire billet.

[0041] 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com