A welding torch adjustment device for laser arc hybrid welding

An adjustment device and electric arc technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex structure, small adjustable range of angle, etc., and achieve the effect of convenient production, simple operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

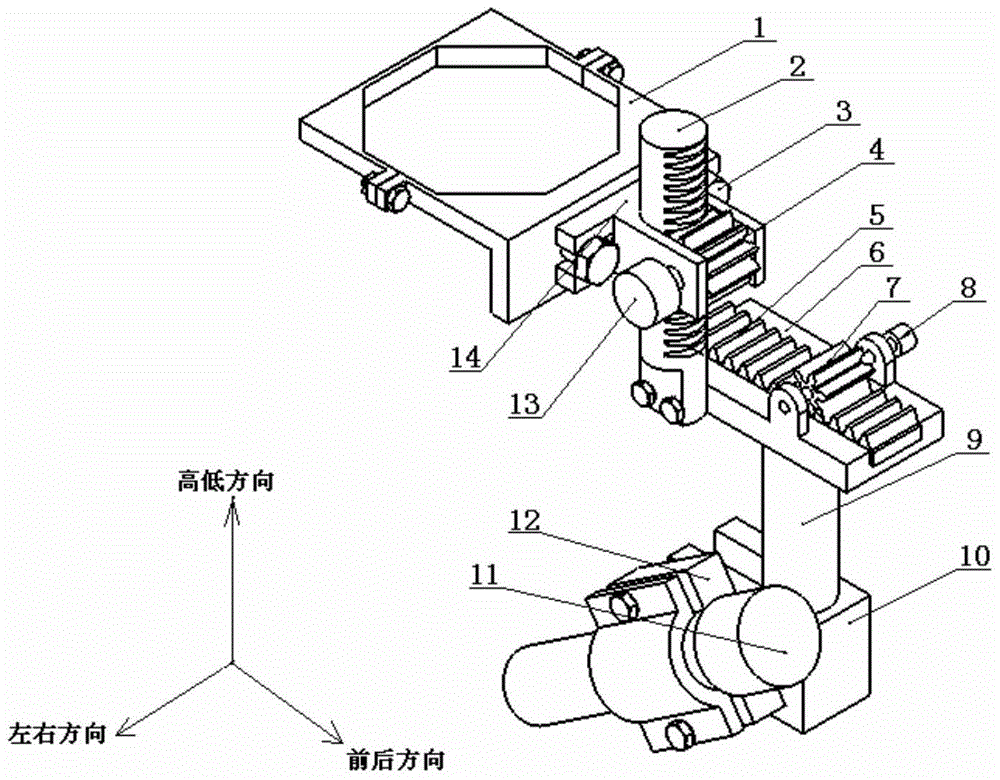

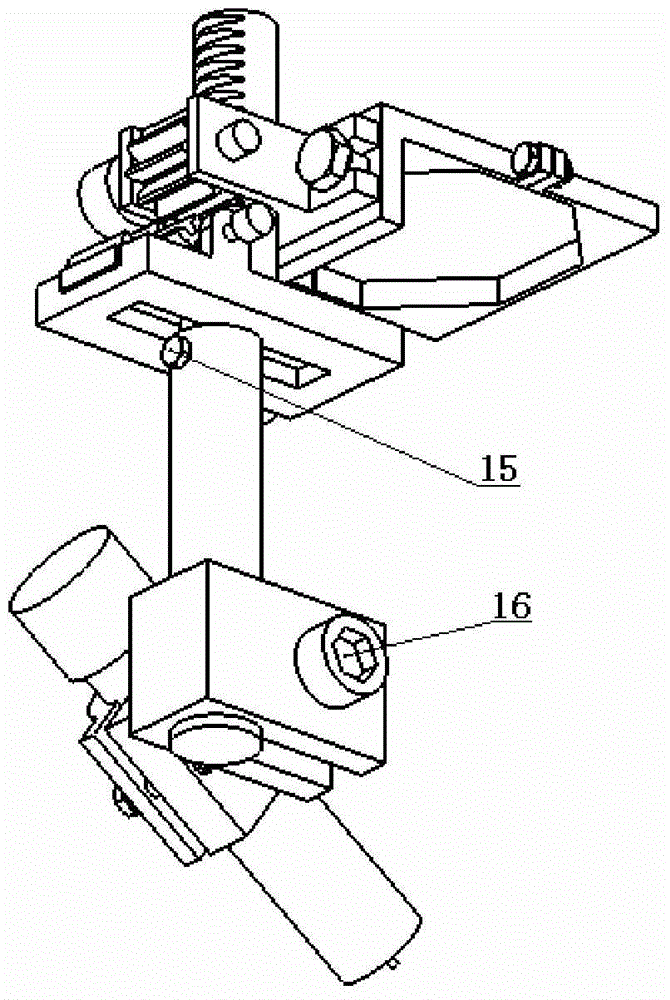

[0023] Such as figure 1 , figure 2 As shown, the laser-arc hybrid welding torch adjustment device includes a laser head jacket 1, a welding torch 11, a front and rear adjustment mechanism, a left and right adjustment mechanism, an up and down adjustment mechanism, and an angle adjustment mechanism. The laser head jacket 1 is connected to the laser welding head. The front and rear adjustment mechanisms are connected with the vertical direction guide column 2, the left and right adjustment mechanisms are connected with the laser head jacket 1, the up and down adjustment mechanisms are connected with the sleeve seat 14, and the angle adjustment mechanism is connected with the angle adjustment guide column 9.

[0024] The front and rear adjusting mechanism is composed of sliding guide rail 6, rack 5, front and rear direction gear 7 and front and rear direction knob 8. There is a concentric groove in the middle of the sliding guide rail 6, and a protrusion under the rack 5 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com