Cleaning and welding integration device for black volume endless rolling

An endless rolling and post-welding technology, applied in the field of cleaning and welding integrated devices, can solve the problems of inability to realize partial cleaning of black coils, waste liquid environment is easy to cause pollution, and cannot be completely removed, so as to suppress arc root drift and reduce The effect of broken belt risk and easy balance regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

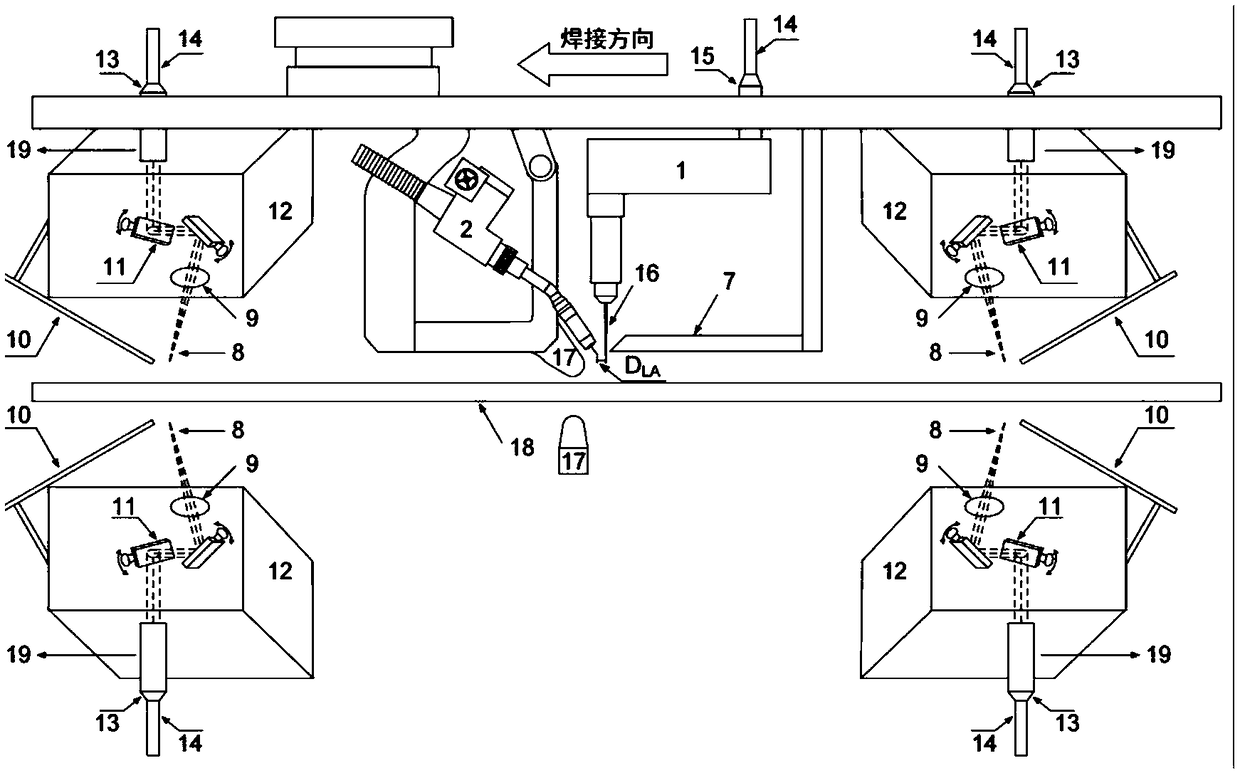

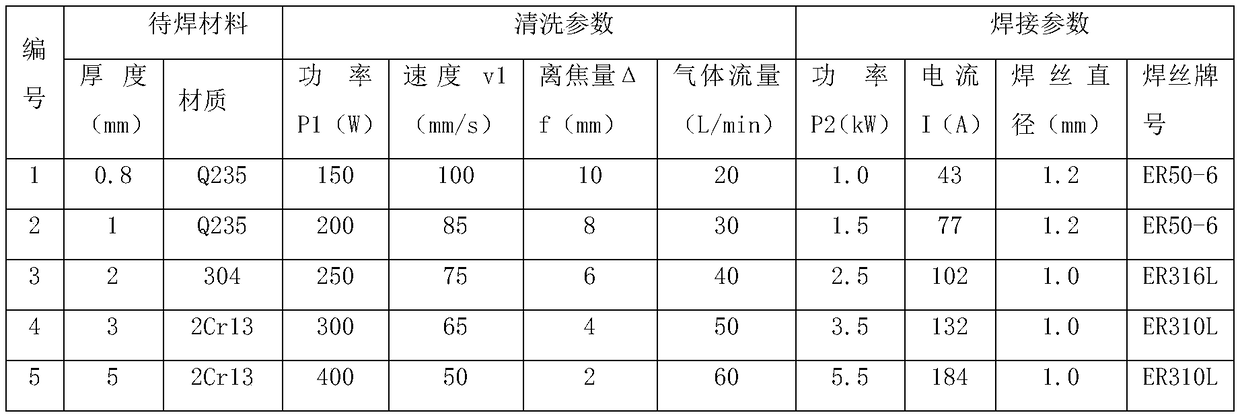

[0048] The workpiece material is 304 austenitic stainless steel black coil with a thickness of 4mm, and the welding method is flat tailor welding.

[0049] In this embodiment, the laser light source is an 8000W fiber laser, the arc heat source is a 320A pulse digitally controlled inert gas welder, and the laser cleaning device is a 500W fiber laser cleaning machine.

[0050] The process parameters of laser cleaning before and after welding in this embodiment are: laser power 300W, cleaning speed 60mm / s, defocus amount 2mm, gas flow 50L / min; the process parameters of laser-arc hybrid welding are: choose ER316L with a diameter of 1.0mm Stainless steel welding wire, shielding gas using Ar+2.5% CO 2 Mixed gas, the gas flow rate is 25L / min, the angle between the vertical laser beam and the arc welding torch is 30°, the distance between the light wires is 3mm, the defocus of the laser beam is -2mm, the laser power is 4500W, the arc current is 150A, and the welding speed is It is 3....

Embodiment 2

[0053] The workpiece material is black coil of 2Cr13 martensitic stainless steel with a thickness of 6mm, and the welding method is flat tailor welding.

[0054] Laser cleaning and composite welding equipment are consistent with Embodiment 1.

[0055] The process parameters of laser cleaning before and after welding in this embodiment are: laser power 450W, cleaning speed 35mm / s, defocus amount 0mm, gas flow rate 60L / min; the process parameters of laser-arc hybrid welding are: choose ER310L with a diameter of 1.0mm Stainless steel welding wire, shielding gas using Ar+2.5% CO 2Mixed gas, the gas flow rate is 20L / min, the angle between the vertical laser beam and the arc welding torch is 40°, the distance between the light wires is 2mm, the defocus of the laser beam is -2mm, the laser power is 7000W, the arc current is 215A, the welding speed It is 2.1m / min.

[0056] The welding process using the above process parameters is stable, and the welding speed has been increased from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Laser power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com