Continuous welding device for laser hybrid welding

A composite welding and welding device technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to align and skew two metal plates, and achieve the effect of convenient continuous welding and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

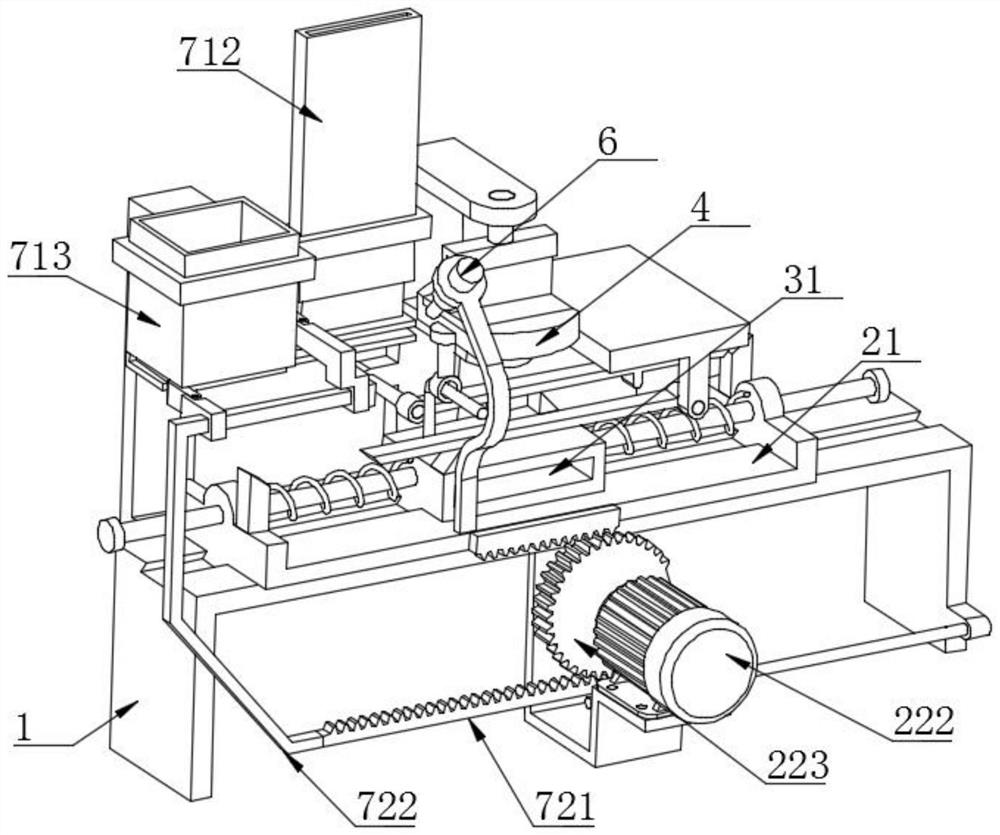

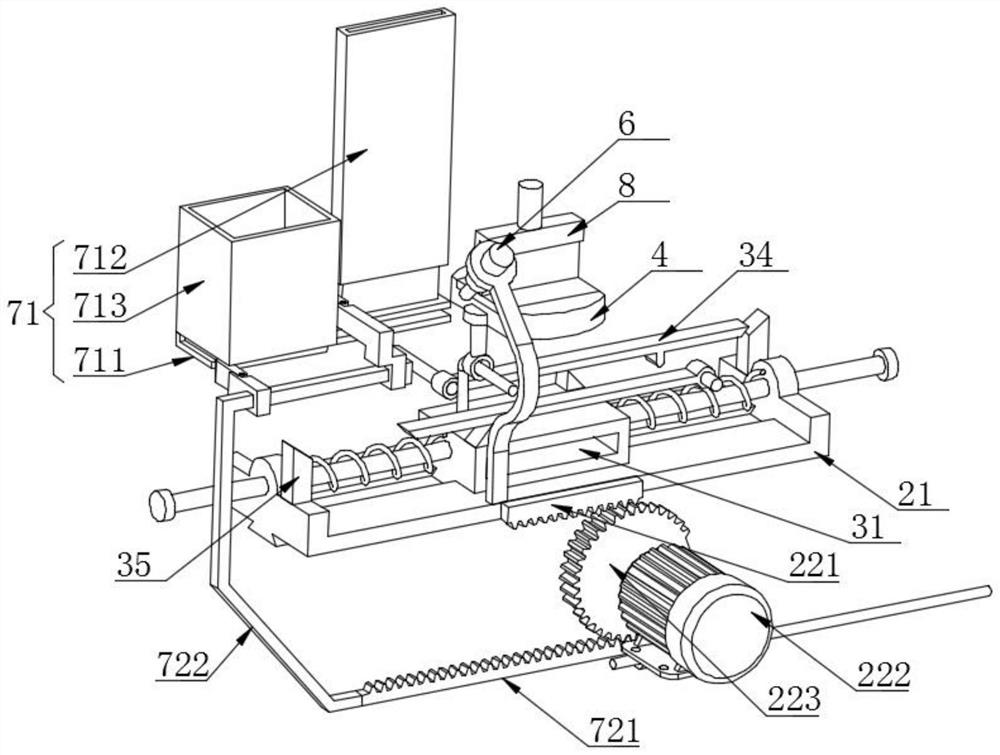

[0035] like Figure 1-9 As shown, a continuous welding device for laser hybrid welding is used for welding metal plate 1 100 and metal plate 2 200 placed perpendicularly to each other, such as Figure 5 As shown, the metal plate 100 is placed horizontally, and the metal plate 200 is vertically placed in the middle of the metal plate 100, and the two sides of the contact position need to be welded, that is, weld A and weld B;

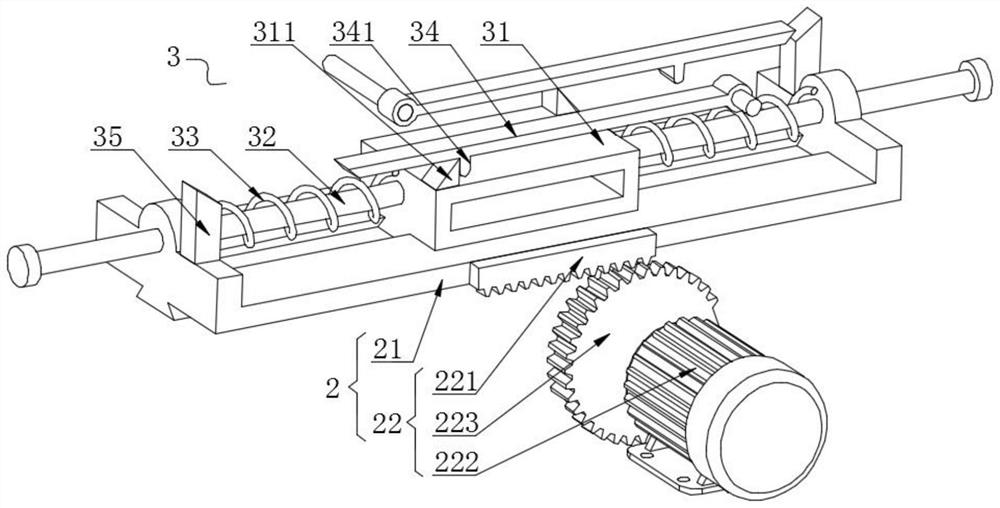

[0036] The welding device includes a frame 1 and a power assembly 2. The power assembly 2 includes a sliding table 21 that slides on the frame 1 and a driving mechanism 22 that drives the sliding table 21 to reciprocate. The sliding table 21 and the frame 1 can use dovetail grooves, etc. Connection, specifically, the driving mechanism 22 includes a rack one 221 fixedly connected with the slide table 21, a driving device 222 installed on the frame 1, a gear 223 connected with the output shaft of the driving mechanism 22, and the gear 223 is connected with...

Embodiment 2

[0046] like Figure 1-2 and Figure 6-8 As shown, on the basis of the first embodiment, the feeding mechanism 7 can be added to automatically feed the first metal plate 100 and the second metal plate 200. Specifically, the feeding mechanism 7 includes a loading mechanism 71, and the loading mechanism 71 includes a The frame 1 is fixedly connected and arranged on the slot plate 711 on one side of the welding table 4, the first barrel 712 and the second barrel 713 that are fixedly connected to the frame 1 above the slot plate 711, and the first barrel 712 is located on the welding table 4. Between the barrel two 713, the inner sides of the barrel one 712 and the barrel two 713 are used to place the metal plate two 200 and the metal plate one 100 respectively, and the metal plate two 200 inside the barrel one 712 can be dropped On the upper surface of the groove plate 711, the metal plate one 100 inside the barrel two 713 can fall on the inner side of the groove plate 711.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com