Preparation method and device of laser cutting and laser hybrid welding combined socketed pipe

A technology of laser cutting and composite welding, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of limited laser welding application, cumbersome process, and high cost, so as to ensure the overall strength and mechanical properties, simple process and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

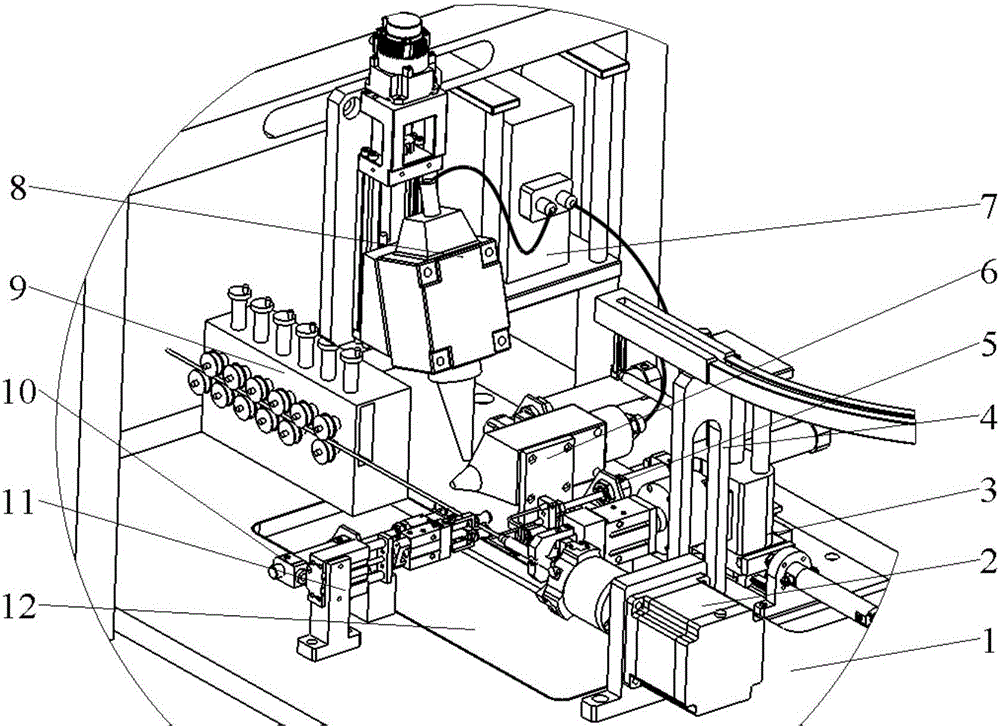

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

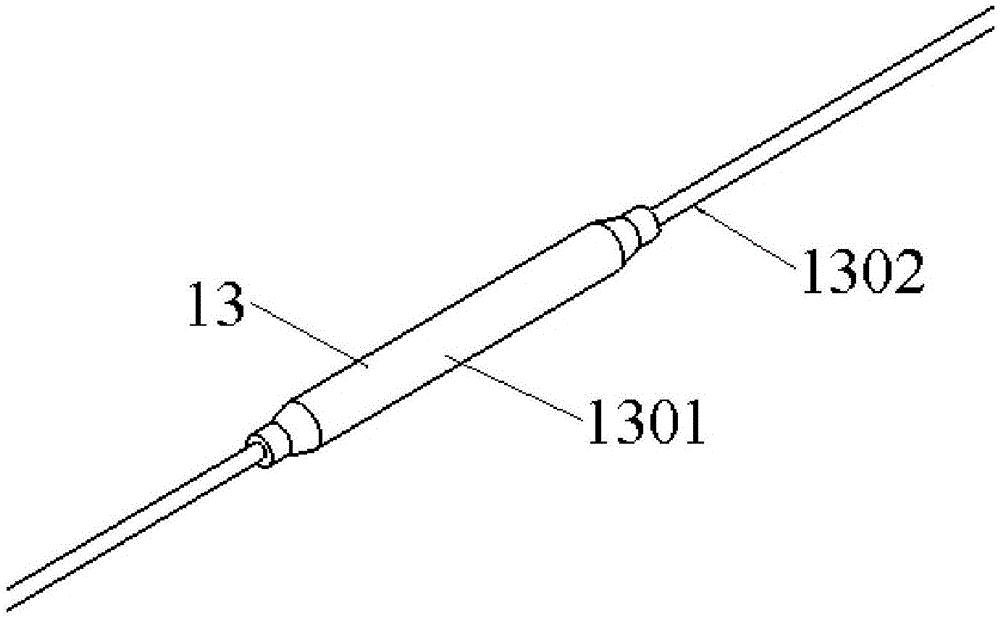

[0056] The present invention provides a method for preparing a socket pipe combining laser cutting and laser hybrid welding, which is used to socket and assemble both sides of a hollow copper pipe 1301 and a hollow copper core 1302 with a slightly smaller diameter, and seal and weld the hollow copper core 1302 to form Artifact 1313. The method specifically includes the following steps:

[0057] (1) clamping hollow copper pipe 1301;

[0058] (2) Insert one end of the hollow copper core 1302 into the hollow copper tube 1301, and the gap between the two is matched, the gap value is 0.01 mm to 0.3 mm, and the socket length is 2 mm to 10 mm;

[0059] (3) A high-frequency induction heating coil is arranged under the socket section of the hollow copper core 1302 and the hollow copper tube 1301, and the shape and size of the coil are requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com