Bipolar plate laser hybrid welding equipment for hydrogen fuel cell

A fuel cell and hybrid welding technology, which is applied in laser welding equipment, fuel cell parts, welding equipment, etc., can solve the problems of waste of equipment capacity, poor yield, and low efficiency, and achieve improved yield and high-efficiency processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

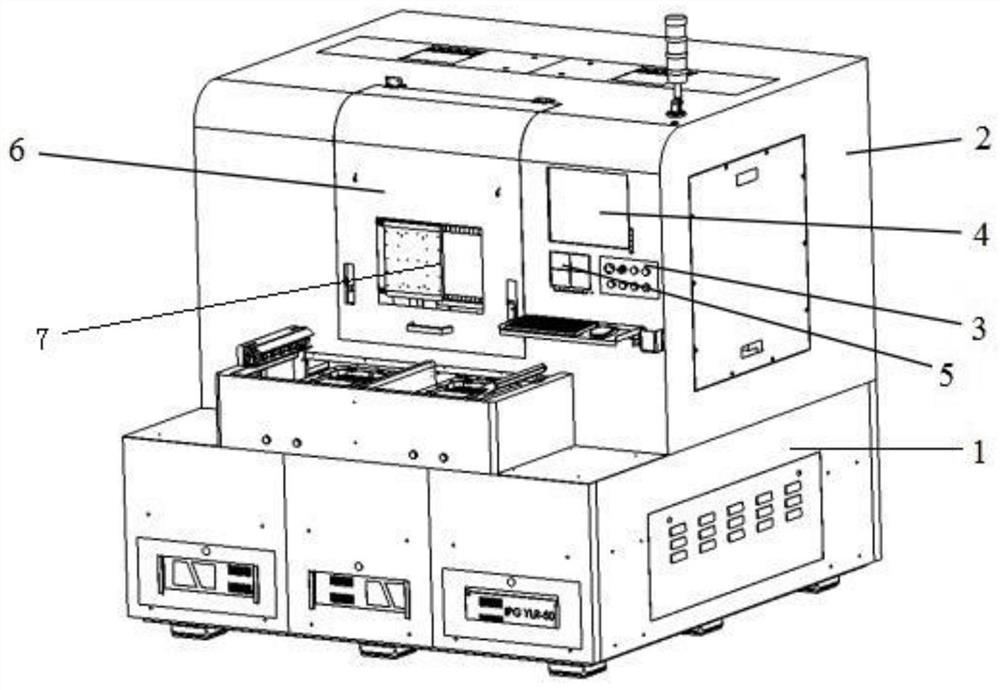

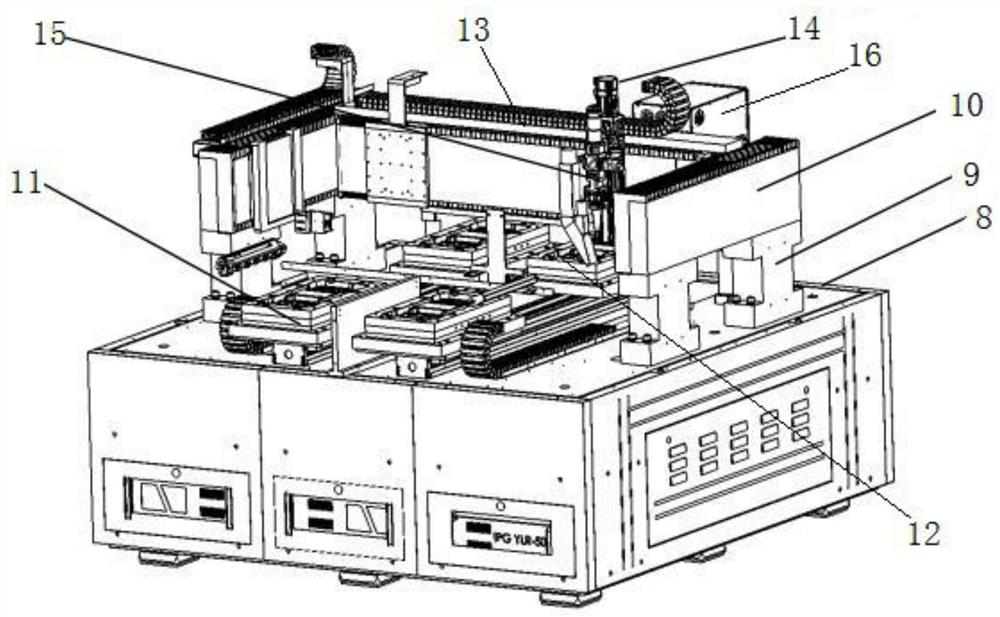

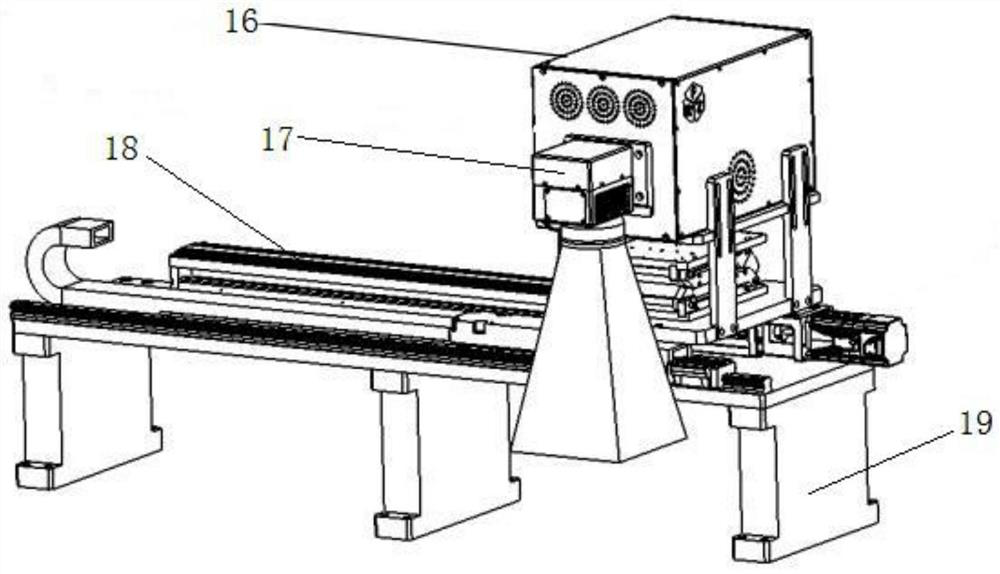

[0019] Such as Figure 1-Figure 3 As shown, a bipolar plate laser composite welding equipment for hydrogen fuel cells in this embodiment includes a cabinet base 1 and a protective cabinet 2 arranged on the cabinet base 1, and the front end of the protective cabinet 2 is provided with a cabinet door 6 , the cabinet door 6 is used to put the bipolar plate to be welded on the jig in the protective cabinet 2 and debug operation; of course, in order to facilitate the welding process in the protective cabinet 2 from the cabinet door 6, the cabinet door 6 A glass observation window 7 of a push-pull structure is provided on the top, specifically there is an opening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com