Laser-hybrid-welding molding equipment for aluminum alloy mobile phone shell and molding process of laser-hybrid-welding molding equipment

A mobile phone shell and molding equipment technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of long production cycle, slow processing speed, low production efficiency, etc., to reduce processing costs, shorten production cycle, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

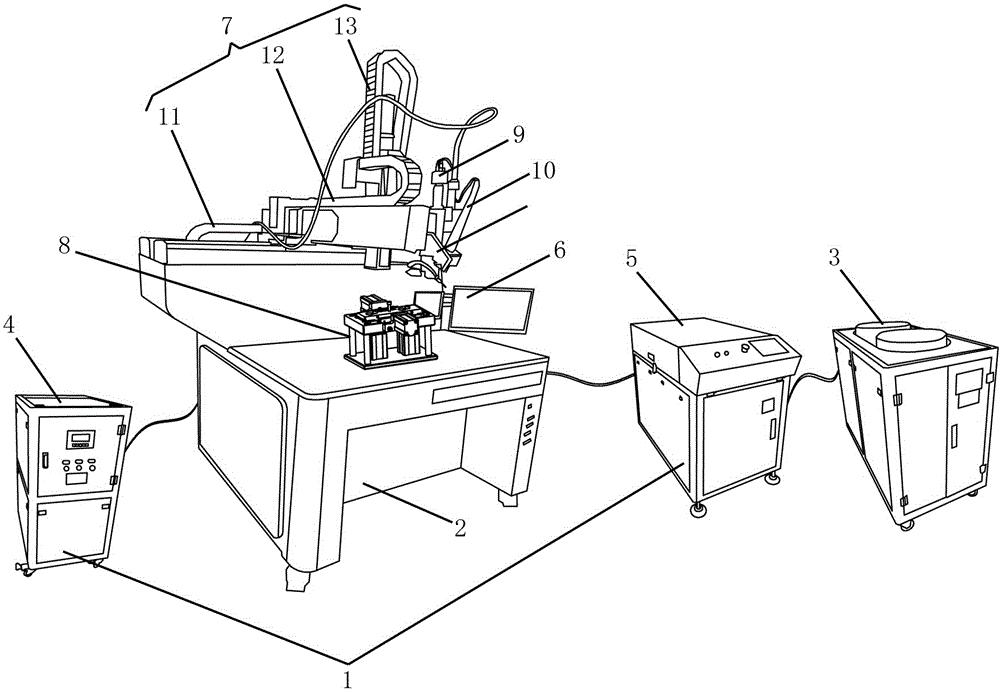

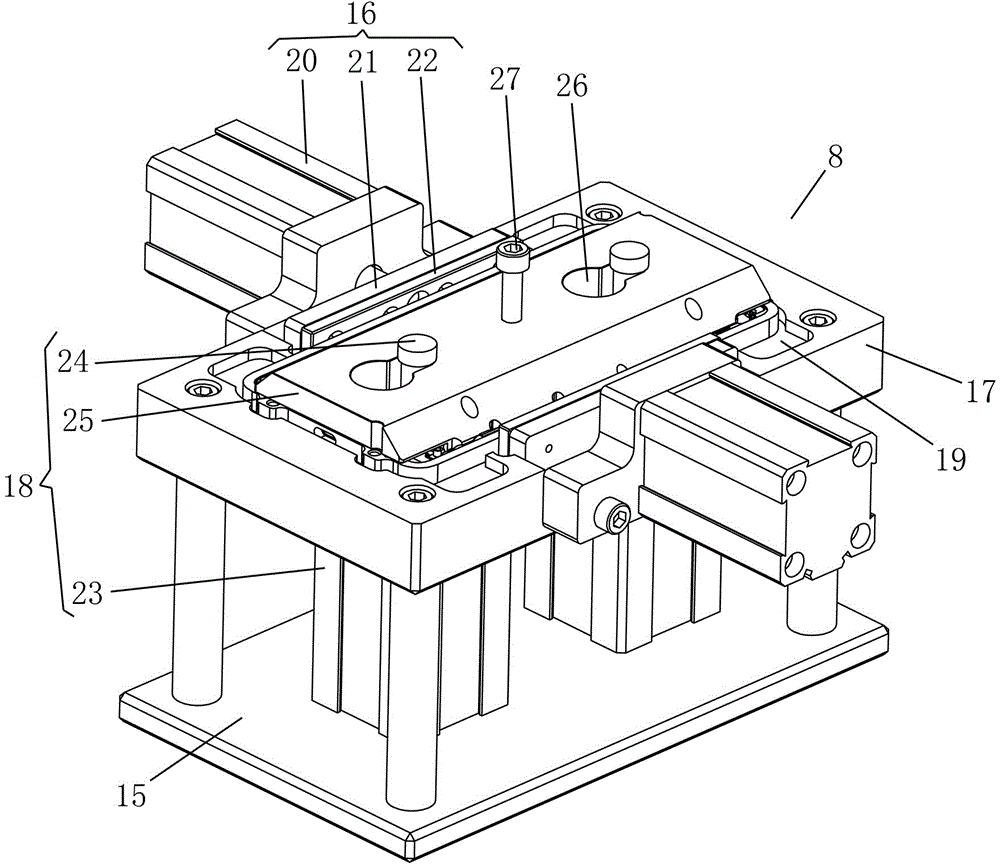

[0025] like Figure 1-2 As shown, an aluminum alloy mobile phone shell laser composite welding forming equipment includes a laser device 1, a welding device 2 and a cooling device 3 electrically connected to each other, and the laser device 1 includes a continuous fiber laser 4 and a pulsed fiber laser 5 , the welding device 2 is provided with a CNC numerical control device 6, a transmission mechanism 7 and a clamping mechanism 8, and the continuous fiber laser 4 and the pulse fiber laser 5 are communicably connected to the CNC numerical control device 6, respectively, The transmission mechanism 7 is equipped with a continuous fiber laser head 9 and a pulse fiber laser head 10, and the continuous fiber laser head 9 and the pulse fiber laser head 10 correspond to the continuous fiber laser 4 and the pulse laser head 10 respectively. The pulsed fiber laser 5, the cooling device 3 is electrically connected to the pulsed fiber laser 5.

[0026] Wherein, the transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com