Laser incidence angle determining method for full penetration laser hybrid welding of T-shaped connector

A technology of laser incident angle and laser incident angle, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as large manpower and material resource consumption, reduce dependence, improve process design efficiency, and reduce process test investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, the laser incidence angle determination method for T-joint full penetration laser hybrid welding, for the T-joint laser arc hybrid welding process of medium and thick plates, if the welded joint is required to be full penetration, the following steps can be adopted Calculation and confirmation of laser incident angle:

[0019] 1. Preliminary calculation of laser incident angle;

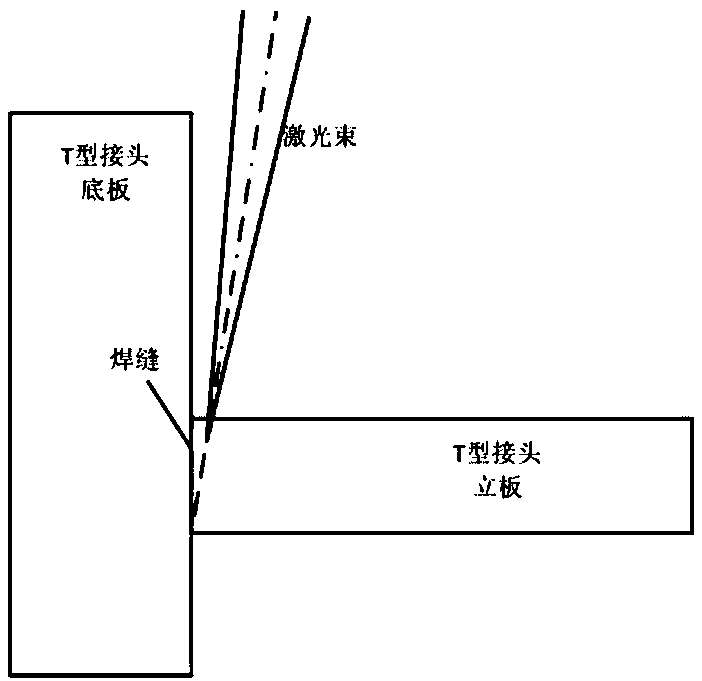

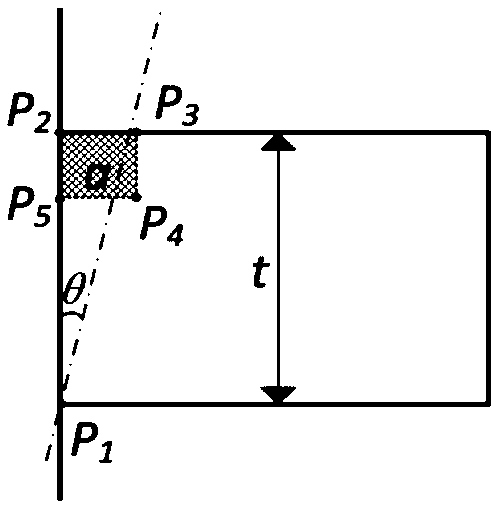

[0020] Preliminary calculation of the incident angle based on the geometric structure of the joint. For a typical T-joint full penetration weld, the beam axis passes through the focal point of the vertical plate and the bottom plate at the root of the weld, and the angle between the laser beam axis and the bottom plate surface is the laser incident angle θ, combined with figure 1 , the laser beam is required to be incident from one side of the vertical plate, and to ensure good fusion on the back of th...

specific Embodiment approach 2

[0027] Specific embodiment two, combine Figure 1 to Figure 4 Describe this embodiment, this embodiment is an example of the laser incidence angle determination method for T-joint full-penetration laser hybrid welding described in the first embodiment,

[0028] Taking the side beam part of S355 material as an example, the T-joint composed of the 12mm vertical plate and the 14mm bottom plate with the inner long weld seam is required to be a full penetration weld seam in the drawing, and the laser incident angle is determined according to the above steps.

[0029] (1) Preliminary calculation of laser incident angle: according to the formula (1) in this method, t=12mm, for the laser-MAG hybrid welding arc action of carbon steel materials, the side length a of the reachable area can be 2.8mm, and the formula ( 1) θ can be obtained max = 16.9°.

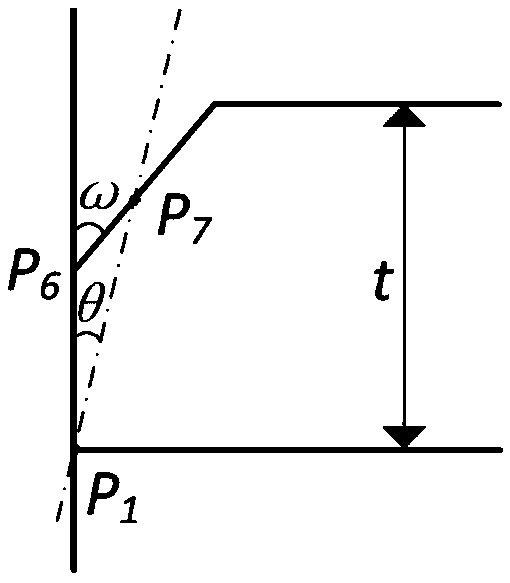

[0030] (2) Interference inspection: due to the irregular shape of the bottom plate of the side member, the Figure 4 In the position s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com