Laser-electric arc hybrid welding method capable of reducing aluminum alloy welding pores

A composite welding and aluminum alloy technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of welding seam inclusions and multiple processes, and achieve the effect of simple method, convenient operation and great use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

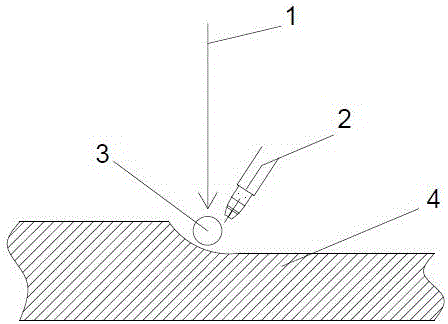

[0021] Such as figure 1 As shown, the method for reducing air holes in aluminum alloy laser-arc hybrid welding provided by the present invention has the following steps:

[0022] Step 1: before welding, the welded part 4 is polished or cleaned, and the welded part 4 after cleaning or grinding is fixed on the welding fixture;

[0023] Step 2: Select a suitable stranded welding wire 3: the diameter is 0.9-1.8mm, the fusion width of the weld is 3-6mm, and the penetration depth is 1-8mm;

[0024] Step 3: Determine the welding parameters;

[0025] Step 4: Start the control switch, pass the shielding gas first, then the welding torch 2 triggers the welding arc, and the laser light source emits the laser beam 1 for welding.

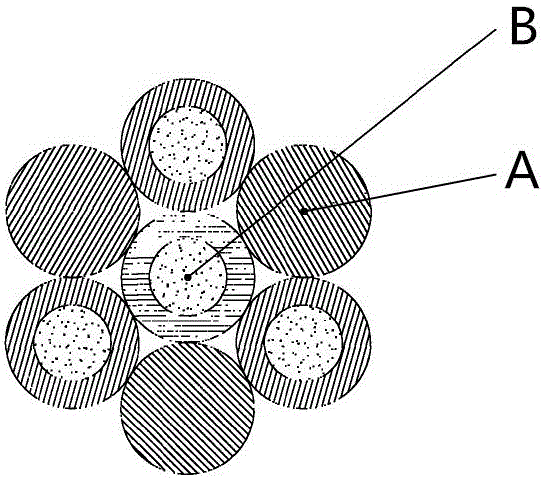

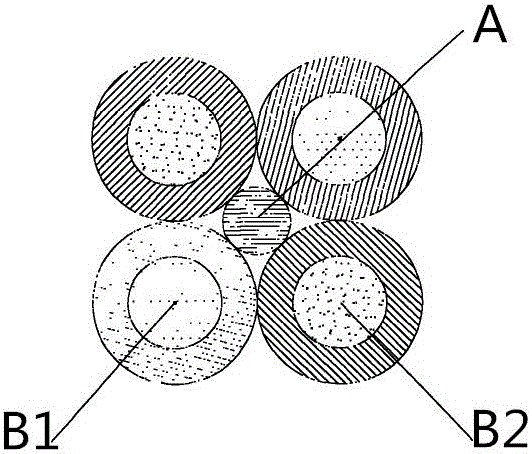

[0026] figure 2 A cross-section of one of the usable stranded welding wires 3 is provided, with flux-cored wire B as the core wire, solid cored wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com