Efficient compound-type hydrate dynamics inhibitor

A kinetic inhibitor, composite technology, applied in drilling compositions, chemical instruments and methods, piping systems, etc., can solve the problem of increasing the risk of hydrate blockage, the influence of supercooling, and the influence of supercooling. and other problems, to achieve the effect of prolonging the formation time of blockage, enduring a large degree of subcooling, and inhibiting the formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

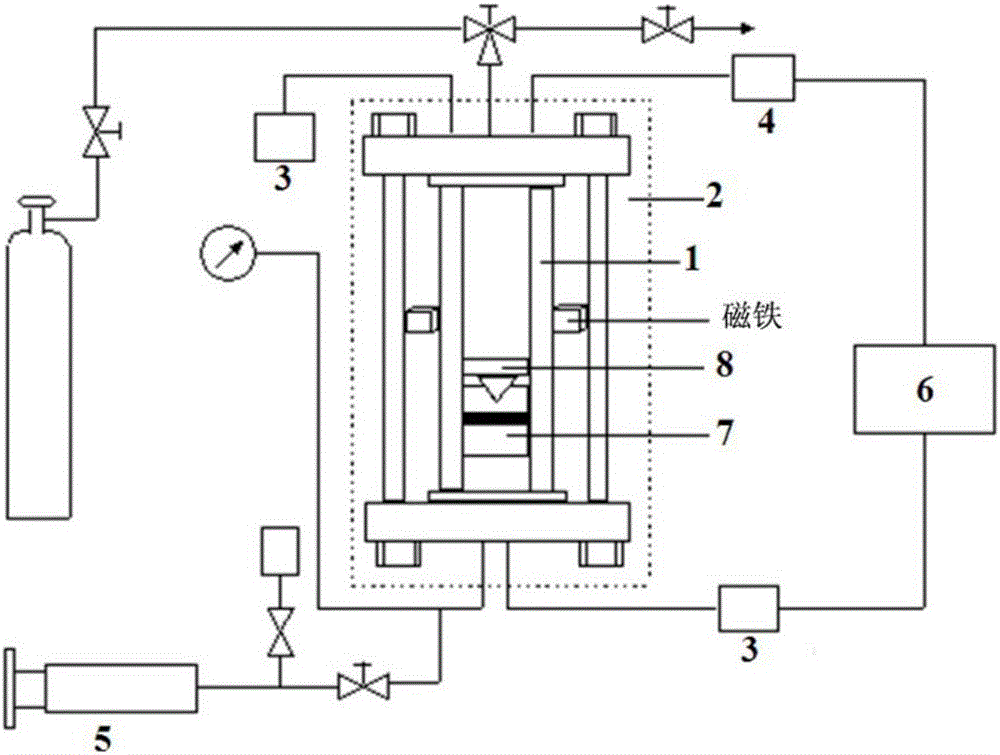

Method used

Image

Examples

preparation example Construction

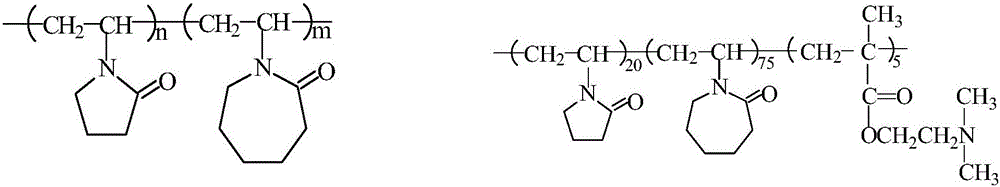

[0035] The present invention also provides a preparation method for the above-mentioned copolymer formed by the reaction of vinylpyrrolidone, vinylcaprolactam and vinylimidazole, which comprises:

[0036] In the first step, vinylpyrrolidone and vinylcaprolactam are added into a reactor with a solvent in a certain proportion, stirred at a constant speed until they are evenly mixed, and heated to a certain temperature;

[0037] In the second step, under the protection of nitrogen, add an initiator, put vinylimidazole into the reaction container, and obtain a solid product after reacting for a certain period of time. After the product is slowly cooled to room temperature, filter the solid product in the reaction solution, and wash and purify it with ether. times, and then vacuum-dried to obtain a copolymer product.

[0038] The mass ratio of the added amounts of vinylpyrrolidone, vinylcaprolactam and vinylimidazole is (0.1-5):(0.1-5):(0.1-10).

[0039] Preferably, the vinylpyrroli...

Embodiment 1

[0070] This embodiment provides a compound hydrate kinetic inhibitor, which is obtained by mixing polyvinyl caprolactam, diethyl monobutyl ether and ethanol at a mass ratio of 2:1:1.

[0071] In this example, the above-mentioned high-pressure transparent sapphire reactor is used for evaluation, and 15ml of deionized water is prepared, and the above-mentioned composite hydrate kinetic inhibitor with a system water quality of 0.5% is added. The experimental pressure is 4.5 MPa, and the experimental temperature is 277.2 K, no hydrate particles appeared in the reactor within 24 hours.

Embodiment 2

[0073] This example provides a composite hydrate kinetic inhibitor, which is obtained by mixing Inhibex501, ethanolamine and ethanol at a mass ratio of 2:1:2.

[0074] In this example, the above-mentioned high-pressure fully transparent sapphire reactor is used for evaluation, and 15ml of deionized water is prepared, and the above-mentioned composite hydrate kinetic inhibitor with a system water quality of 1.0% is added. The experimental pressure is 4.5MPa, and the experimental temperature is 277.2 K, no hydrate particles appeared in the reactor within 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com