Laser continuous repair welding method

A laser, repair welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as air tightness and strength cannot be effectively guaranteed, appearance is not beautiful, repair welding efficiency is low, etc., to achieve good sealing , low cost, high repair welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] When there are bad defects such as explosive points, virtual welding, and broken welding after welding the power battery sealing nail, the method of continuous repair welding of the fiber laser of the present invention is adopted. The present invention has great application value in the repair welding of the power battery sealing nail. The field of laser welding technology.

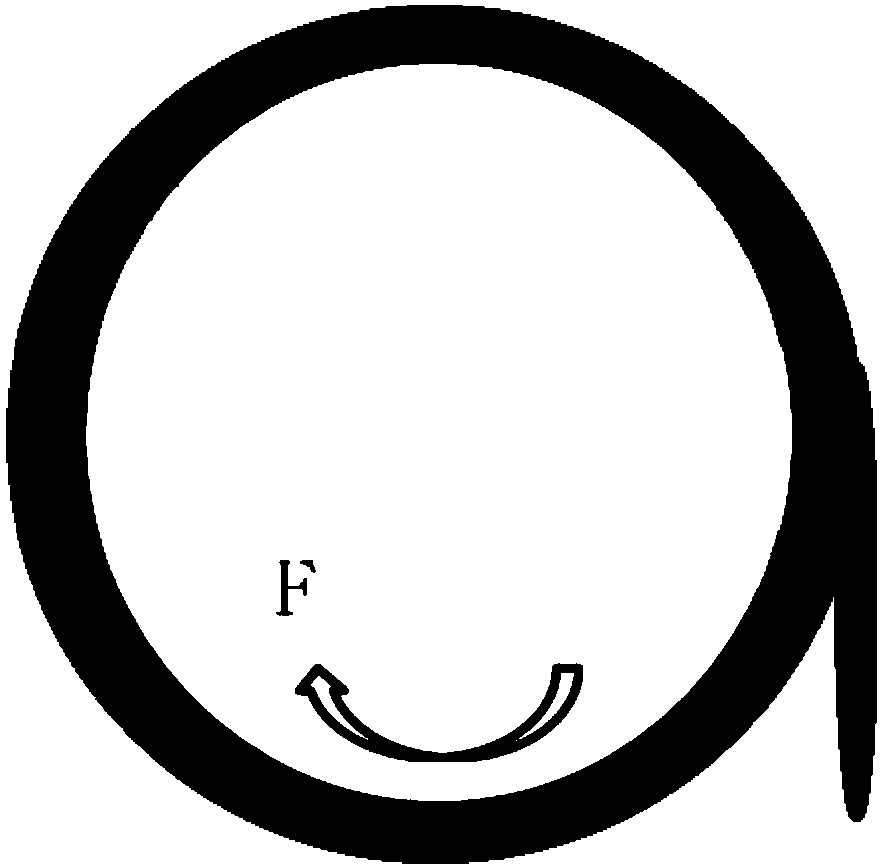

[0023] For batteries with defects such as explosion points and broken welding after continuous laser welding, existing production equipment can be used for repair welding, and the repair welding power is the same as the welding parameters of the first time. figure 1 Shown is a schematic diagram of sealing nail welding and welding track, figure 1 F shown is the welding direction.

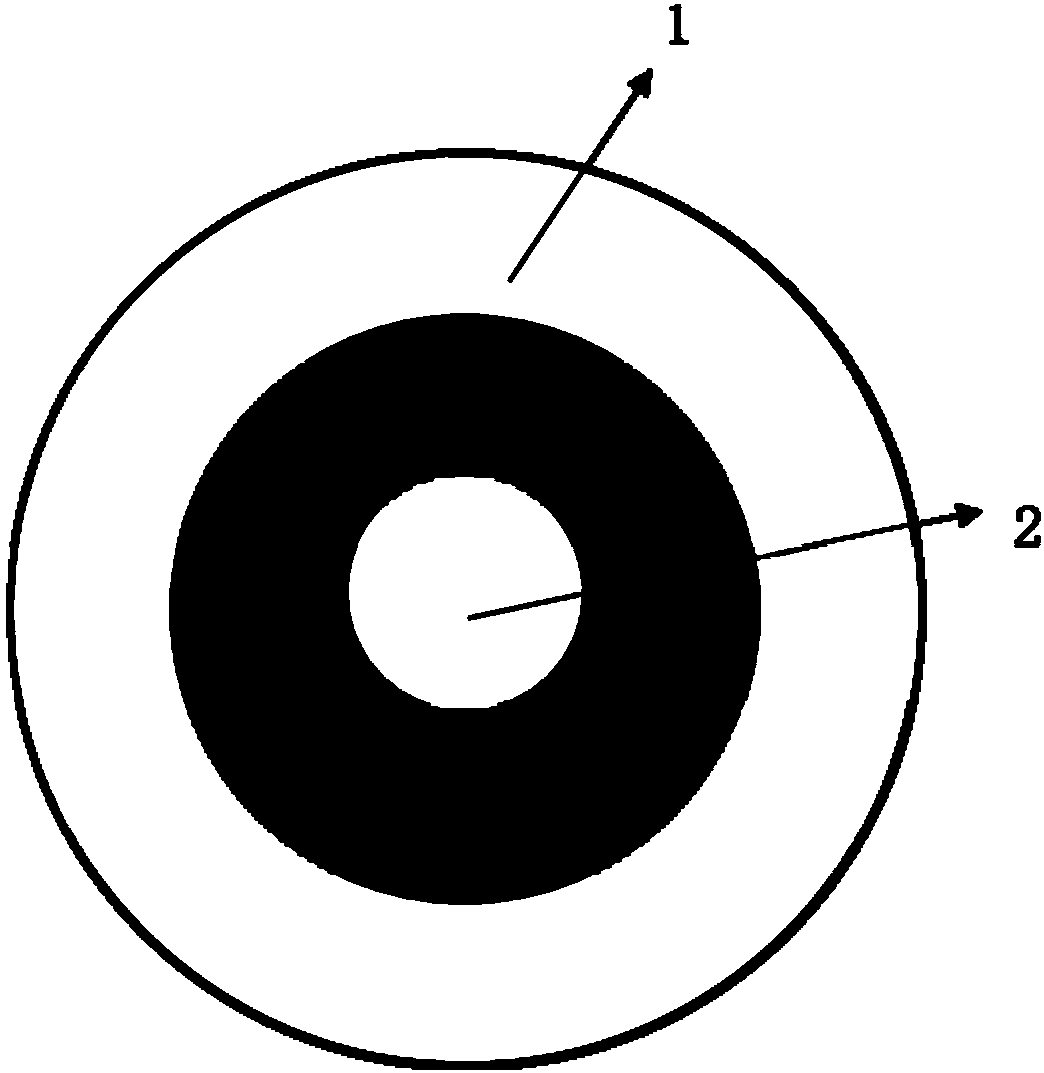

[0024] Generally, the size of the battery sealing nail is 7.8mm in diameter, and a laser cleaning is an area composed of circles with a diameter between 4mm and 14mm. Such as figure 2 As shown, when repairing welding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com