Steel-aluminum compounding finned tube and processing method thereof as well as heat exchanger manufactured by same

A technology of steel-aluminum composite and finned tubes, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reduced tightness of the overall heat exchanger, increased on-site assembly workload, and high cost , to avoid the hot-dip galvanizing process, reduce the assembly workload and ensure the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

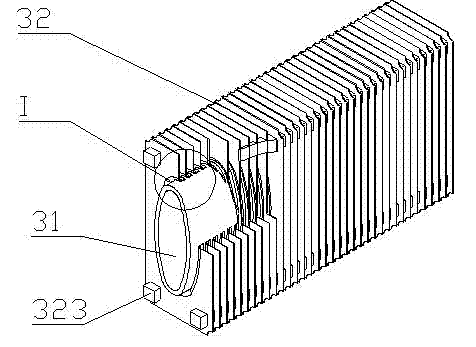

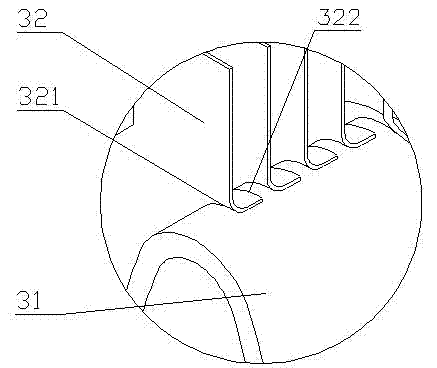

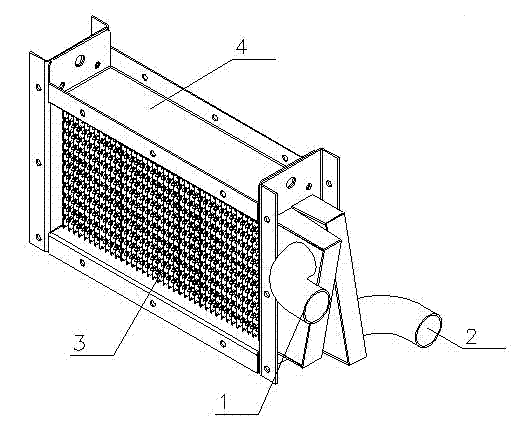

[0025] The structure of the steel pipe aluminum finned tube described in this embodiment is as attached figure 1 , 2 As shown, the finned tube is composed of a base tube 31 and a plurality of fins 32, wherein the base tube 31 can be selected as an elliptical tube, a round tube or a tube of other shapes. In this embodiment, the elliptical tube is selected to help improve heat transfer. performance. The base pipe 31 is made of a steel pipe coated with an aluminum composite material. The base pipe 31 is rolled and welded, with a wall thickness of 1.5mm.

[0026] The fins 32 described in this embodiment are rectangular fins, which are punched from an alloy composite aluminum plate material by a punching machine, and an oval-shaped pipe-through opening 321 corresponding to the shape of the base pipe 31 is arranged in the middle, and the pipe-through opening 321 A crimp 322 is formed at the hole 321 to facilitate close contact with the base pipe 31 . The fins are provided with f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com