Overlap laser-arc hybrid welding of coated steel sheets

A laser arc, coating steel plate technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of forming quality, welding efficiency, bubble slag inclusion defects, etc., to achieve efficient and stable welding, forming Excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

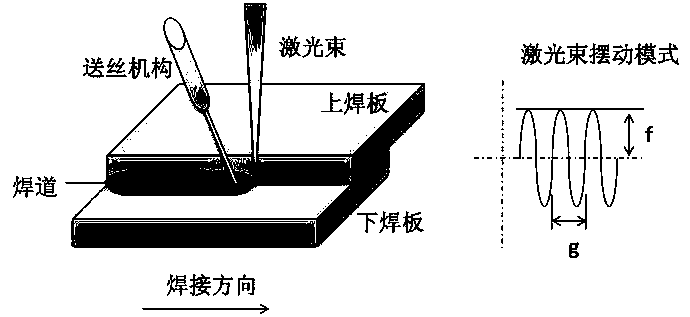

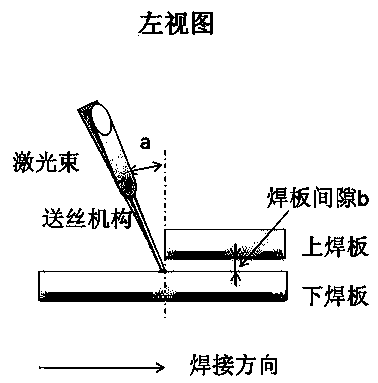

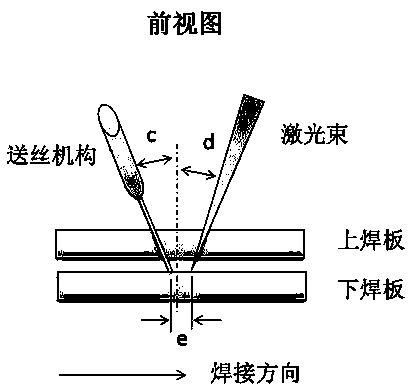

[0053] Use 1.5mm thick galvanized steel plate for upper and lower lap welding.

[0054] The laser beam spot diameter is 23mm, the welding wire diameter is 0.8mm, the dry elongation is 16mm, the welding speed is 3.2m / min, and the shielding gas is Ar+5-20% CO 2 , the flow rate is 35L / min, see Table 1 for other parameters.

[0055] The quality inspection results of welded joints are shown in Table 2.

Embodiment 3-4

[0057] Use 2.5mm thick galvanized steel plate for upper and lower lap welding.

[0058] The laser beam spot diameter is 25mm, the welding wire diameter is 1.0mm, the dry elongation is 18mm, the welding speed is 3.0m / min, and the shielding gas is Ar+5-20% CO 2 , the flow rate is 35L / min, see Table 1 for other parameters.

[0059] The quality inspection results of welded joints are shown in Table 2.

Embodiment 5-6

[0061] Use 4.0mm thick aluminized steel plate for upper and lower lap welding.

[0062] The laser beam spot diameter is 27mm, the welding wire diameter is 1.2mm, the dry elongation is 20mm, the welding speed is 2.8m / min, and the shielding gas is Ar+5-20% CO 2 , the flow rate is 35L / min, see Table 1 for other parameters.

[0063] The quality inspection results of welded joints are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com