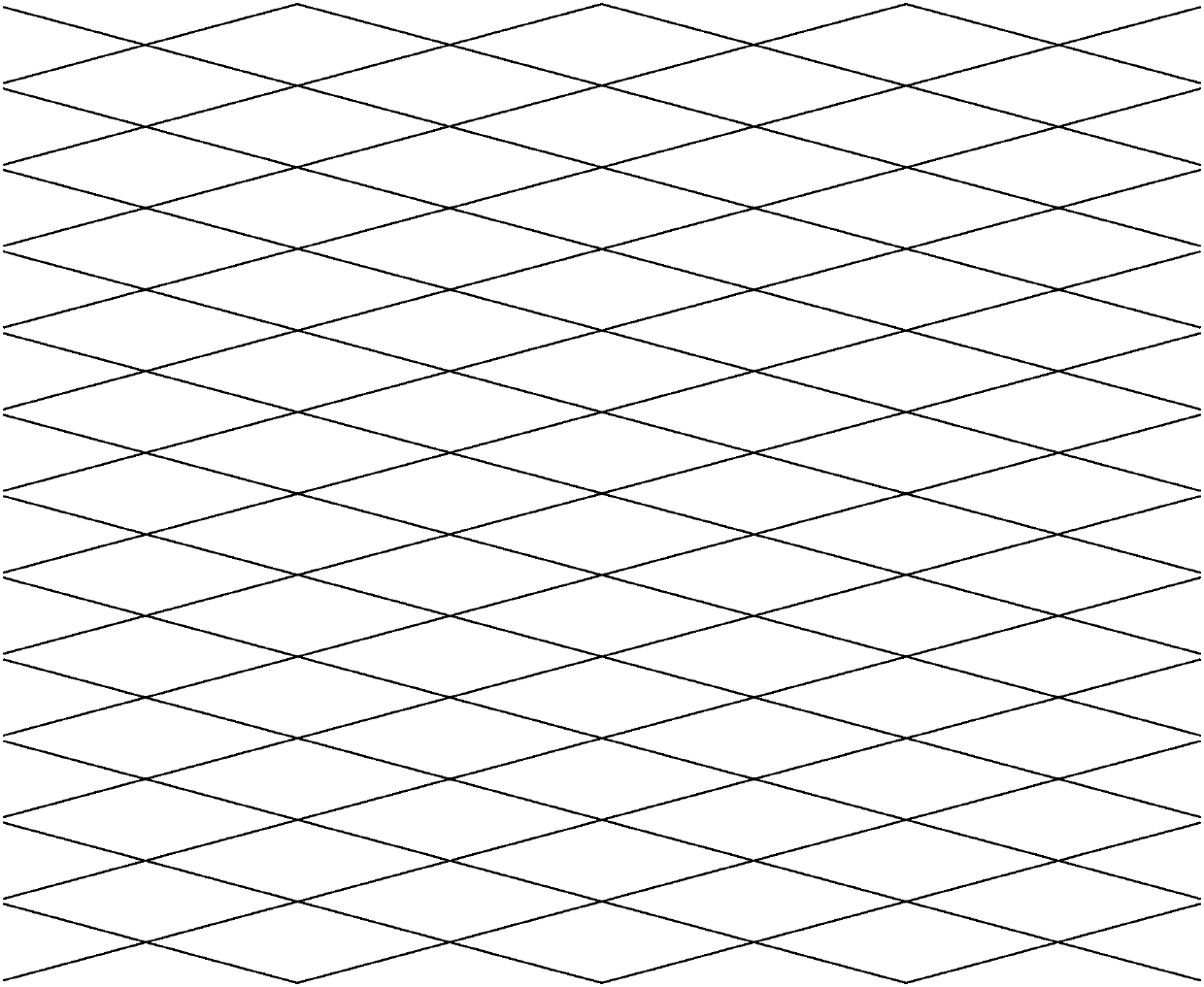

Aluminized steel sheet mesh and preparation method thereof

An expanded metal mesh and aluminized technology, applied in the expanded metal mesh field, can solve the problems such as the application limitation of stainless expanded mesh, complicated expanded metal mesh technology, poor processing performance, etc. Grinding characteristics, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

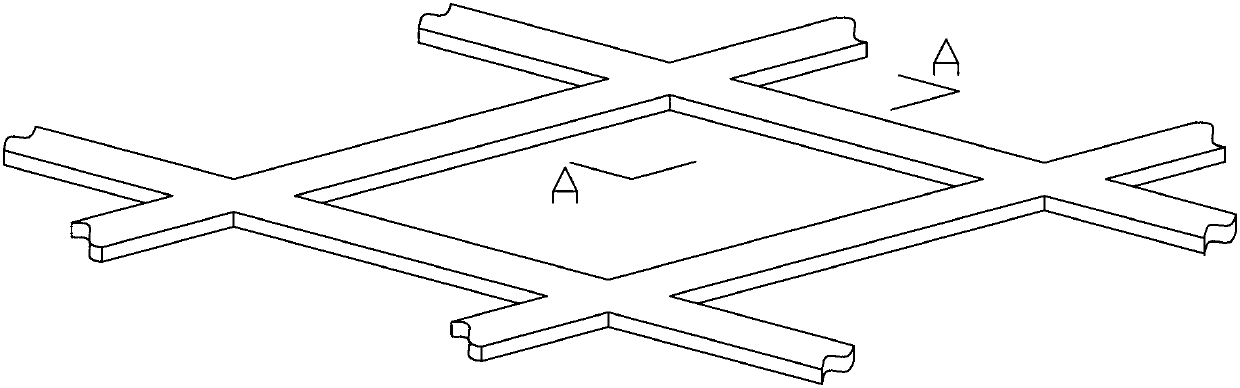

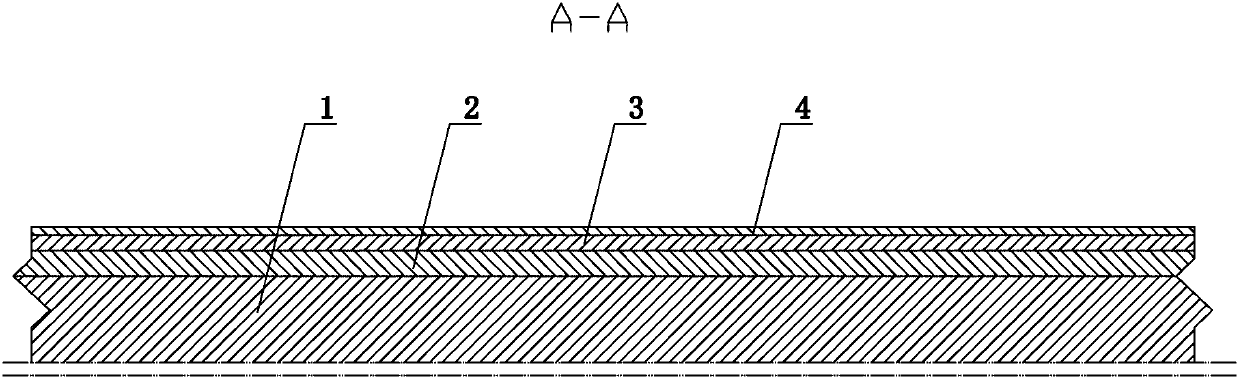

[0074] 1. Send the steel plate into the expanded metal mesh punching and shearing machine, and become the expanded metal mesh body after punching and stretching.

[0075] 2. The wire stem thickness of the manufactured steel mesh workpiece is 3.0mm, the short pitch is 36mm, the long pitch is 100mm, the wire stem width is 4.05mm, the mesh width is 2000mm, and the mesh length is 4000mm.

[0076] 3. Baking and degreasing, chemically degreasing the expanded metal mesh workpiece, and baking and degreasing treatment in the temperature range of 410°C for 10 minutes until the surface is clean and oil-free.

[0077] 4. Pickling and derusting, the expanded steel mesh workpiece after degreasing is immersed in pickling solution, the component of the pickling solution is wt98H with a mass percentage of 3% 2 SO 4 , 17% wt36HCl, and the balance is water; pickling is carried out in a sulfuric acid pool with alternating current, the current value is 50A, the power frequency is 10kHz, and the p...

Embodiment 2

[0085] 1. Send the steel plate into the expanded metal mesh punching and shearing machine, and become the expanded metal mesh body after punching and stretching.

[0086] 2. The wire stem thickness of the manufactured steel mesh workpiece is 3.0mm, the short pitch is 36mm, the long pitch is 100mm, the wire stem width is 4.05mm, the mesh width is 2000mm, and the mesh length is 4000mm.

[0087] 3. Baking and degreasing, chemically degreasing the expanded metal mesh workpiece, and baking and degreasing treatment in the temperature range of 425°C for 10 minutes until the surface is clean and oil-free.

[0088] 4. Pickling and rust removal, the expanded steel mesh workpiece after degreasing is immersed in pickling solution, the component of the pickling solution is wt98H with a mass percentage of 2.5% 2 SO 4 , 16% wt36HCl, and the balance is water; pickling is carried out in a sulfuric acid pool with alternating current, the current value is 40A, the power frequency is 9kHz, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com