Aluminized steel and preparation method thereof

A technology of aluminized steel and aluminized, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of easy pollution of dissolved iron, long pickling time of workpiece, final bending performance, toughness stamping forming performance damage and other problems, to reduce the incidence of leakage, eliminate the influence of hydrogen embrittlement, and improve the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

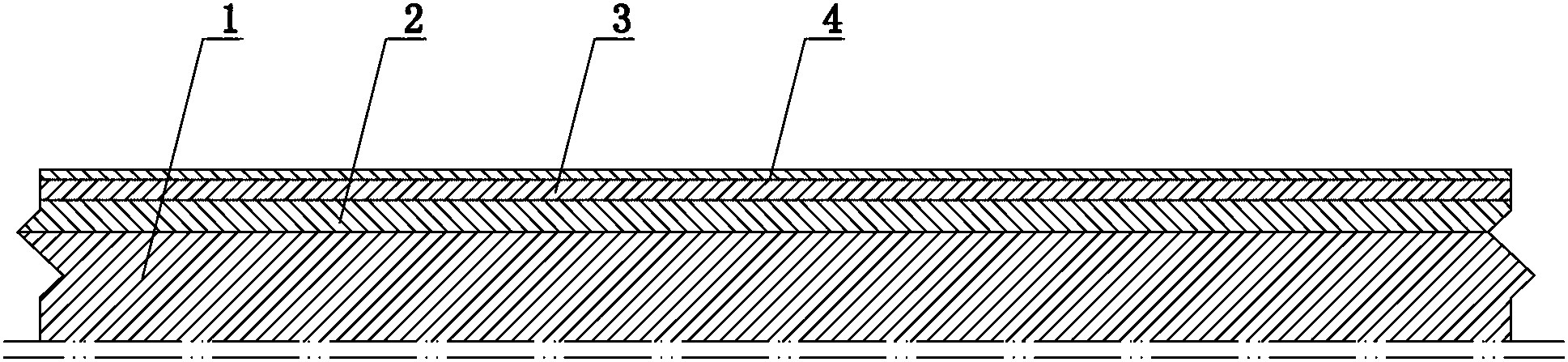

[0070] A preparation method for preparing the above-mentioned aluminized steel, comprising the following steps:

[0071] 1. Bake the steel workpiece to degrease; chemically degrease the steel workpiece 1, and degrease the steel workpiece 1 in the temperature range of 400°C~450°C for 10 minutes until the surface is clean and free of oil.

[0072] 2. Pickling and derusting; the steel workpiece 1 after degreasing is immersed in the pickling solution, and the component of the pickling solution is wt98H with a mass percentage of 2~3% 2 SO 4 , 15~17% wt36HCl, and the balance is water.

[0073] Preferably, the pickling step is carried out in a pickling tank with an alternating current, the current value is 30-50A, the power frequency is 8-10kHz, and the pickling time is 2-3 min. In this way, the time of pickling is greatly shortened, and the concentration of acid is also reduced.

[0074] 3. Water washing; the steel workpiece 1 after derusting is washed 1 or 2 times with high-pres...

Embodiment 2

[0085] Different from Example 1, this example is heated to 680°C by means of induction heating, and the aluminum liquid component in this example is aluminum liquid containing 0.5-0.8% lead and 0.04-0.08% antimony by mass percentage.

[0086] Preferably, the aluminum liquid component is an aluminum liquid containing 0.7% lead and 0.06% antimony by mass percentage. The aluminum liquid of this component can reduce the heating temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com