Steam condenser of vacuum plant

A technology of steam condenser and vacuum device, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., and can solve the problems of increased film heat transfer, reduced total heat transfer coefficient, and reduced heat exchange performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

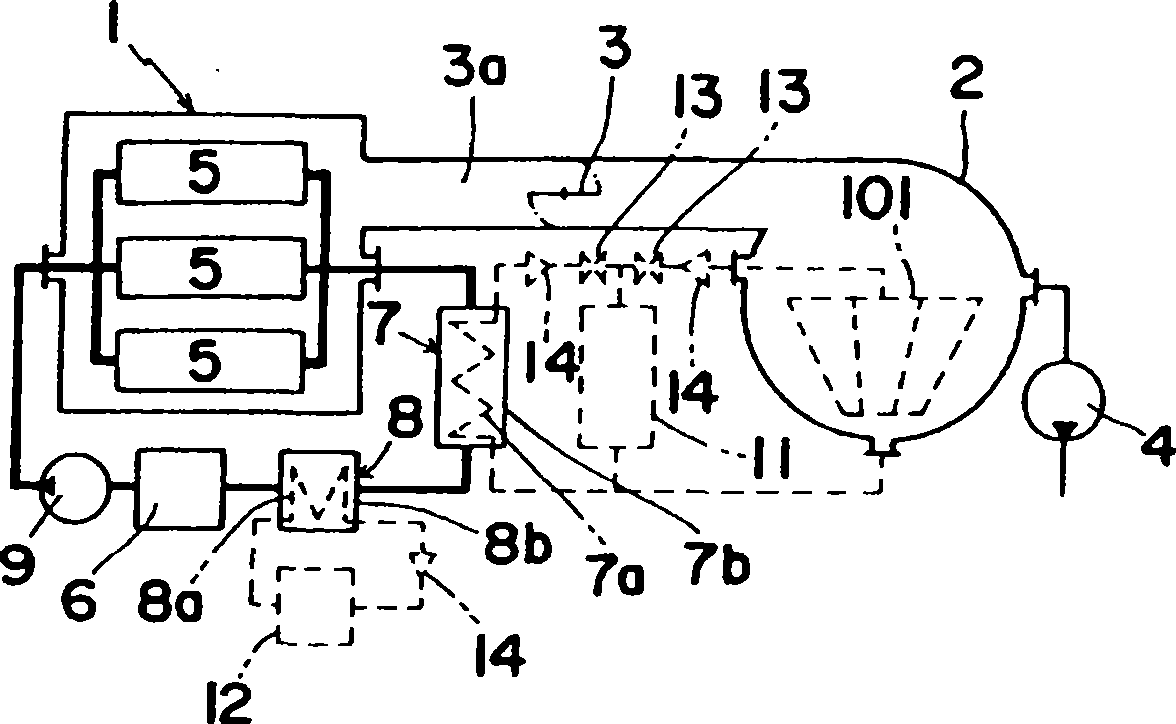

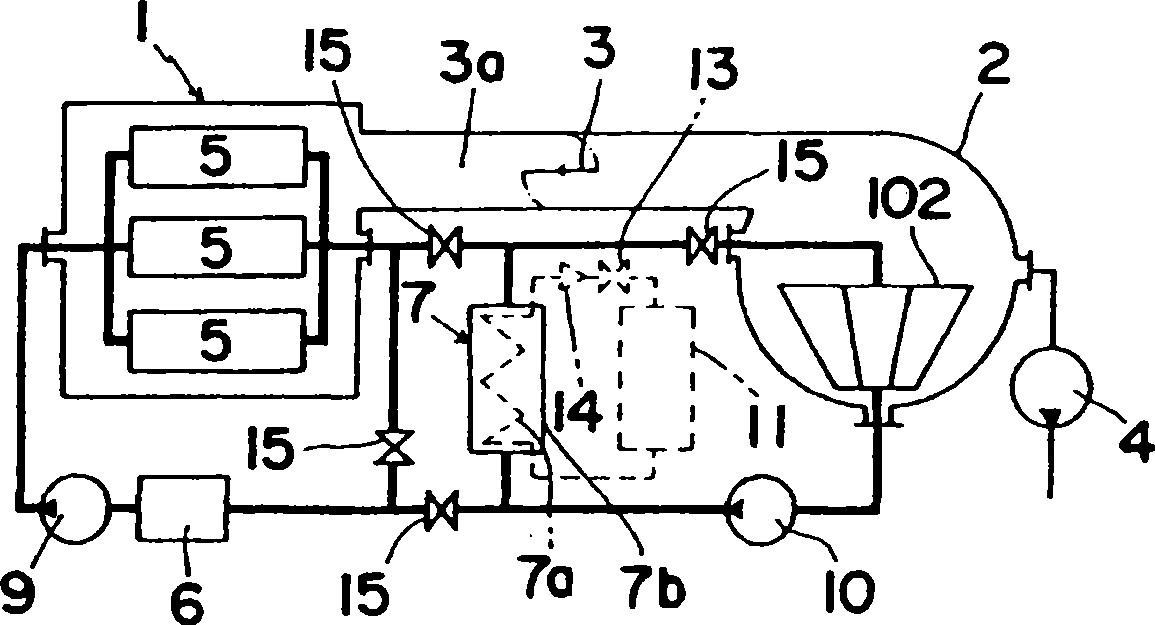

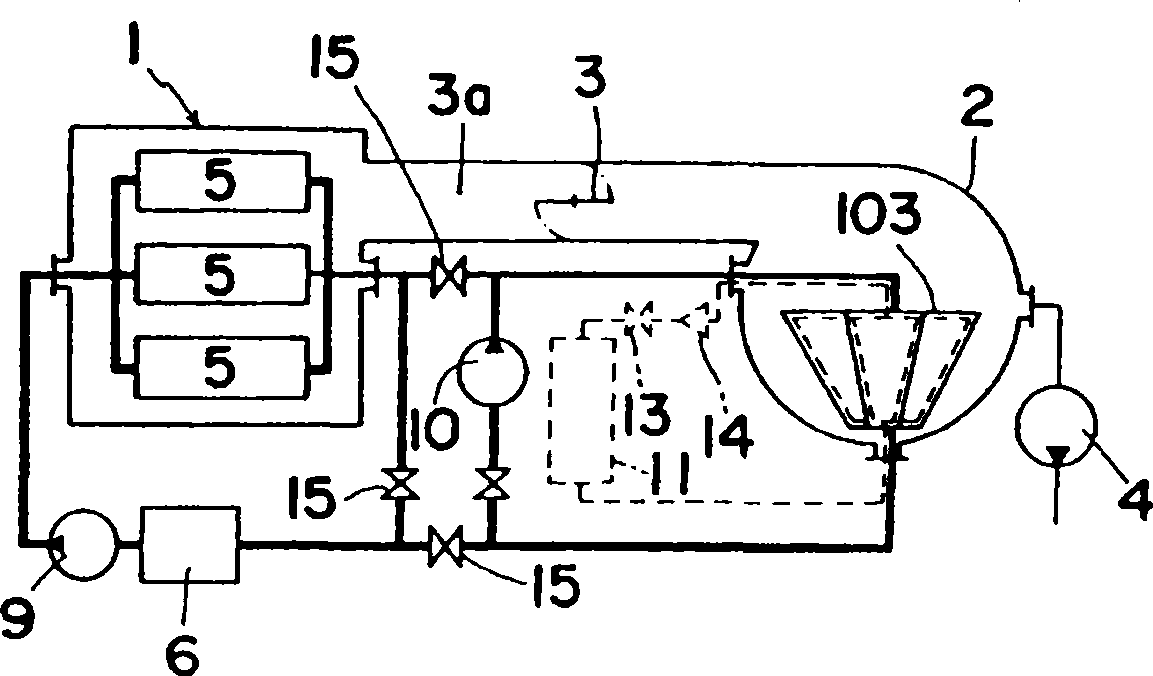

[0059] The embodiments are described in detail below according to the accompanying drawings. In addition, as for the reference numerals in the drawings, the same reference numerals are used for the same components as those in the conventional proposal.

[0060] Figure 9 It is a longitudinal sectional view of a steam condensing plate a constituting a part of the steam condenser (collector) 103 provided in the vacuum apparatus implementing the prior invention. Plate, symbol w represents the passage formed inside the steam condenser plate a, symbol B represents the heat transfer medium liquid circulating inside the passage w, and reference numeral 26 represents the refrigerant pipe installed through the inside of the passage w, symbol R represents the refrigerant circulating in the refrigerant tube 26 . In addition, the refrigerant tube 26 is deformed into an elliptical tube 16, and the inner peripheral surface thereof has a concavo-convex portion y provided with a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com