Reverse dust collector with eddy plate

A dedusting device and reverse technology, applied in waste heat treatment, energy industry, cement production, etc., can solve problems such as boiler wear, heat exchange efficiency drop, damage, etc., to reduce maintenance costs, eliminate load increase, suppress wear and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

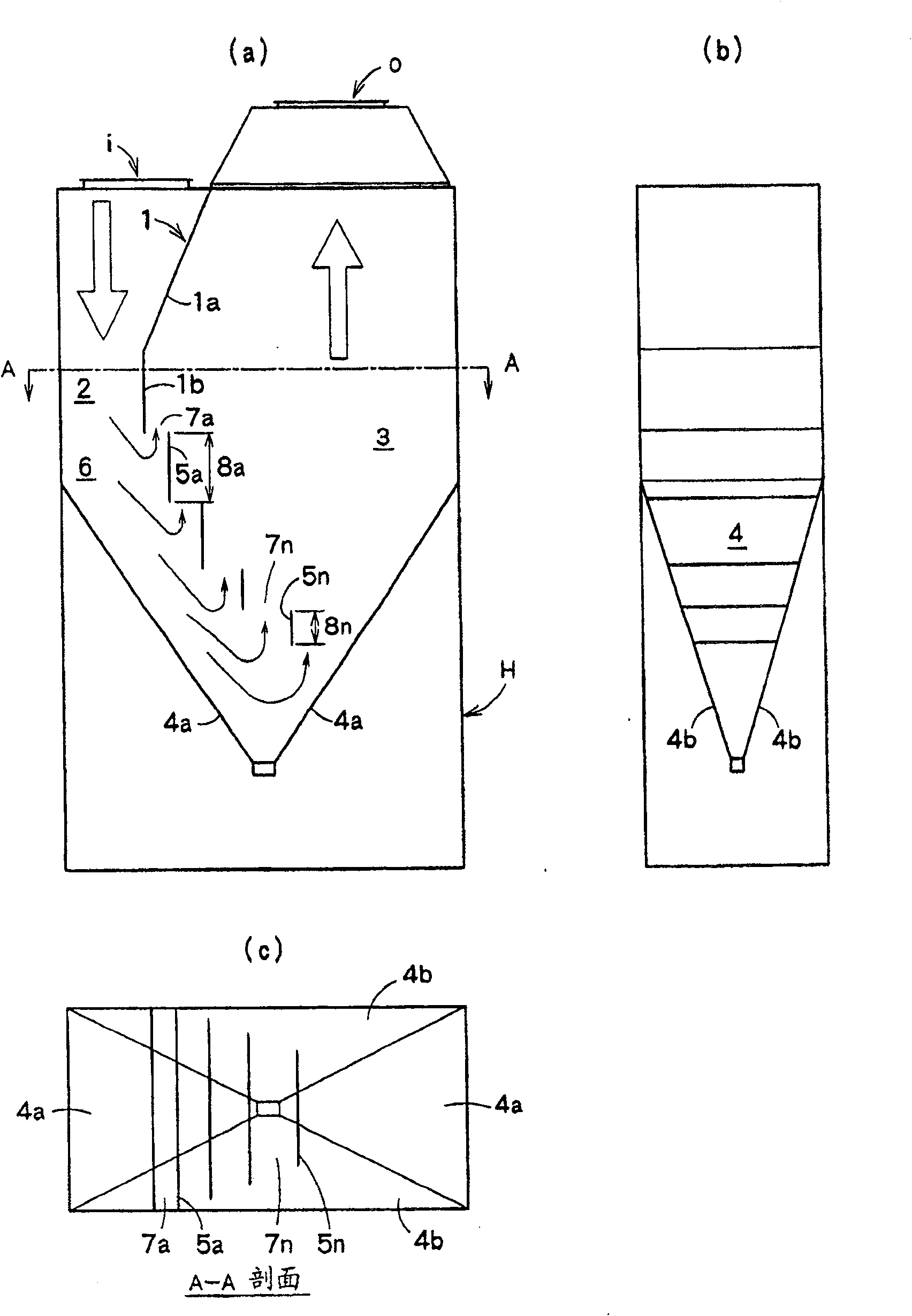

[0058] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

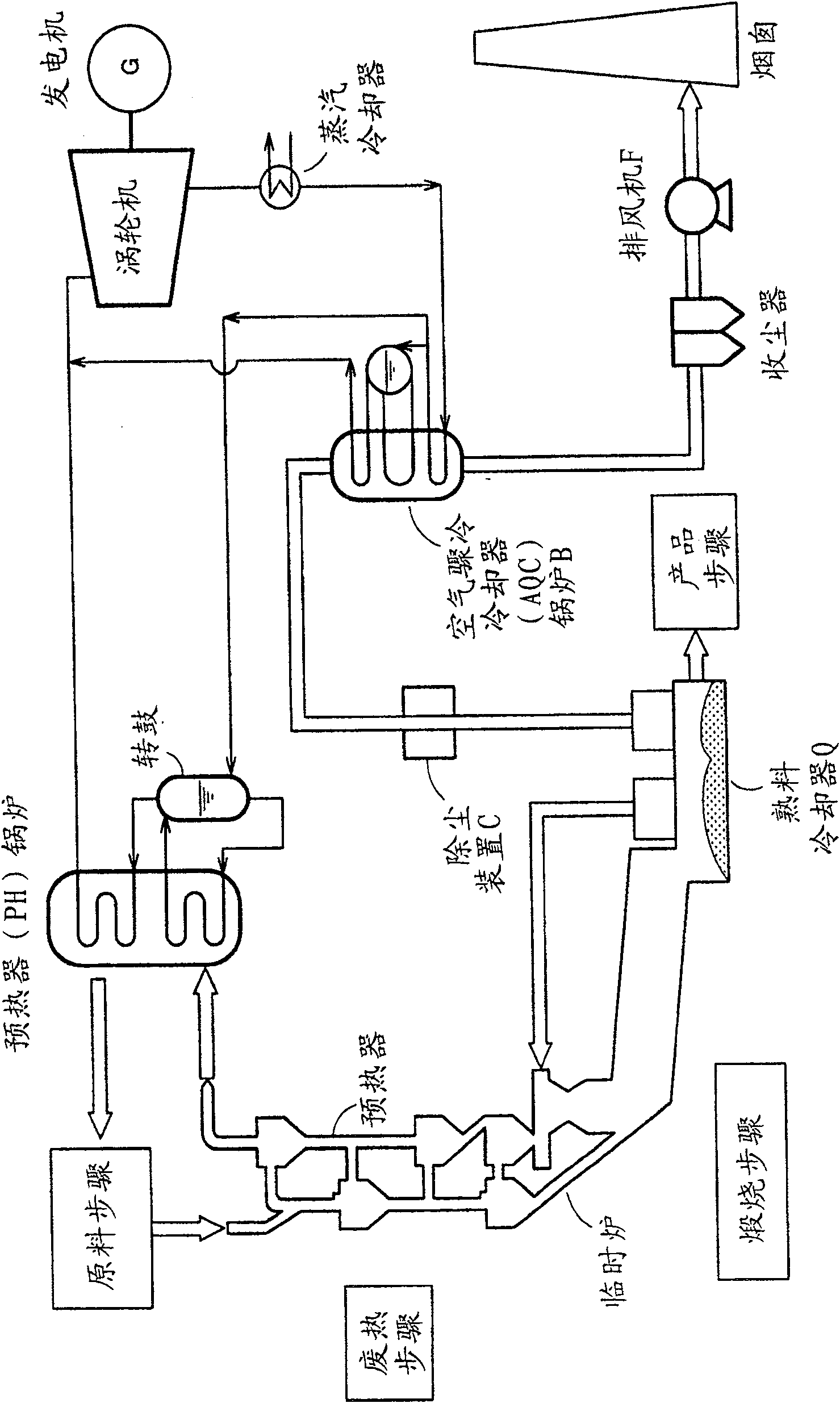

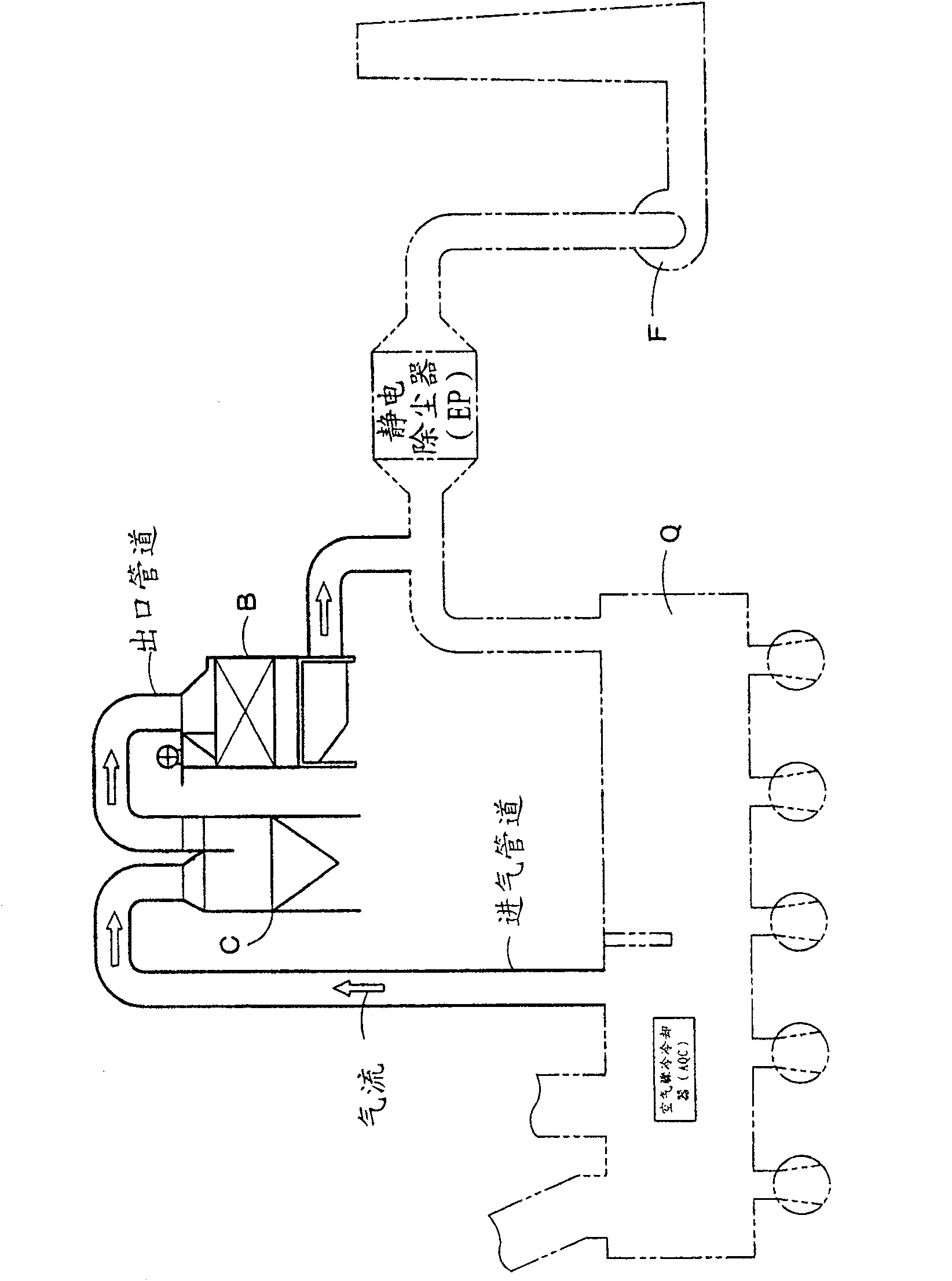

[0059] This embodiment is a system in which the exhaust gas at a higher temperature discharged from the intermediate stage of the air quench cooler Q as a clinker cooler is processed through a dust removal device (dust collector) C for dust removal ,Such as figure 2 shown in . Next, the exhaust gas is supplied to the AQC boiler B, returns to the exhaust pipe, is discharged through the exhaust fan F, and is discharged from the chimney.

[0060] Exhaust gas discharged from the intermediate stage of the air quench cooler (AQC) Q and supplied to the AQC boiler B (at about 360°C and a flow rate of 1800Nm 3 / min) includes a large amount of dust having diameters of various sizes, such as a particle diameter of 1.0 mm or less. Exhaust flow rate is about 1800Nm 3 / min, and is discharged at a flow rate of 15m / s through the exhaust fan on the downstream side of AQC boiler B. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com