High-speed railway subgrade considering vibration reduction and freezing prevention

A technology for high-speed railways and roadbeds, applied in roads, buildings, ballast layers, etc., can solve the problems of low stability, poor heat preservation effect of roadbeds, affecting railway stability, etc., to improve protection performance, reduce heat exchange capacity, improve The effect of antifreeze ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

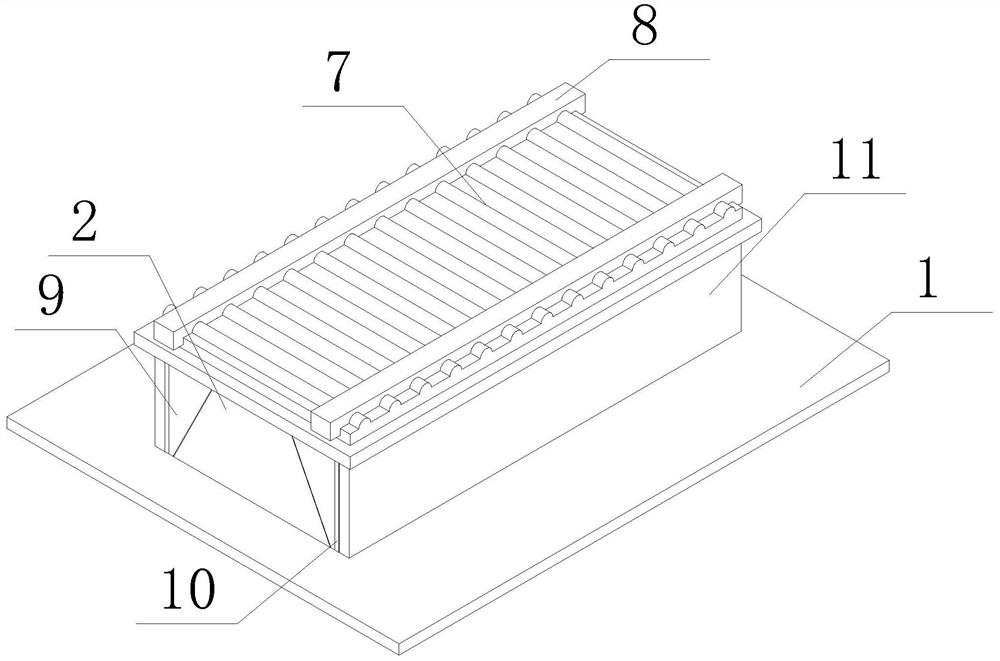

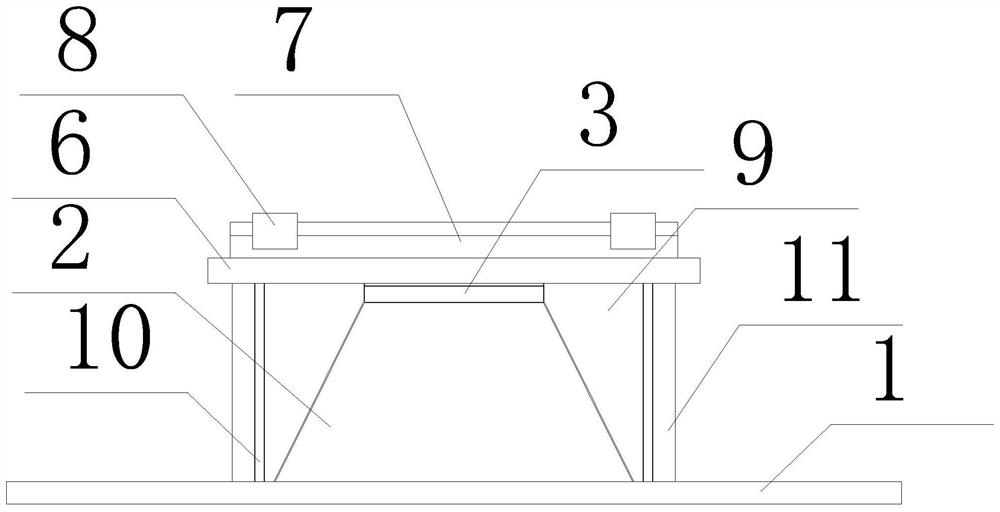

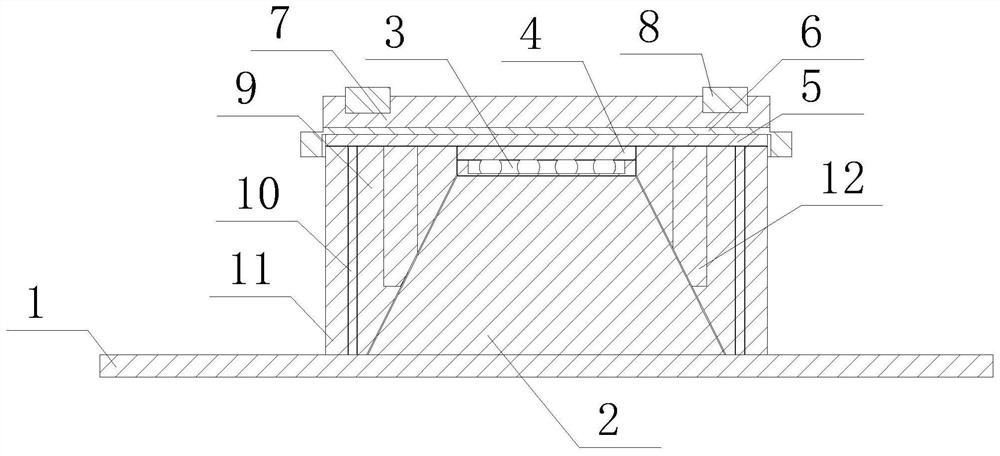

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0023] Such as Figure 1-4 As shown, a high-speed railway embankment that takes into account vibration reduction and antifreeze includes a ground 1, the top of the ground 1 is fixedly connected with a railway bed 2, and the end of the railway bed 2 away from the ground 1 is fixedly connected with a gravel layer 3. The end of the stone layer 3 far away from the railway bed 2 is fixedly connected with the road basic body 4, and the end of the road basic body 4 away from the gravel layer 3 is fixedly connected with the insulation layer 5, and the end of the insulation layer 5 away from the road basic body 4 is fixedly connected with the protective layer 6, The end of the protective layer 6 away from the insulation layer 5 is fixedly connected with a shock absorber 7, and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com