Low permeability gas reservoir turning repeated fracturing technological method

A technology of repeated fracturing and process method, which is applied in the field of petroleum fracturing, and can solve the problems of reducing oil and gas well production, difficulty in degrading plugging agents, and easy closure of temporary plugging parts of fractures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In low-permeability and ultra-low-permeability gas wells, especially in non-water-producing gas wells, there is a problem that this type of plugging agent is difficult to degrade, which affects the effect of diversion fracturing, and even leads to the temporary plugging of fractures after the ineffective diversion agent is degraded. It is easy to close, resulting in the reduction of fracture conductivity and the production of oil and gas wells. The present invention conducts scientific and reasonable analysis on the above situation, and provides a low-permeability gas well diversion refracturing process, in which all links are closely connected and mutually confirmed, and the low-permeability gas well diversion refracturing process using a new type of fracture diversion agent method.

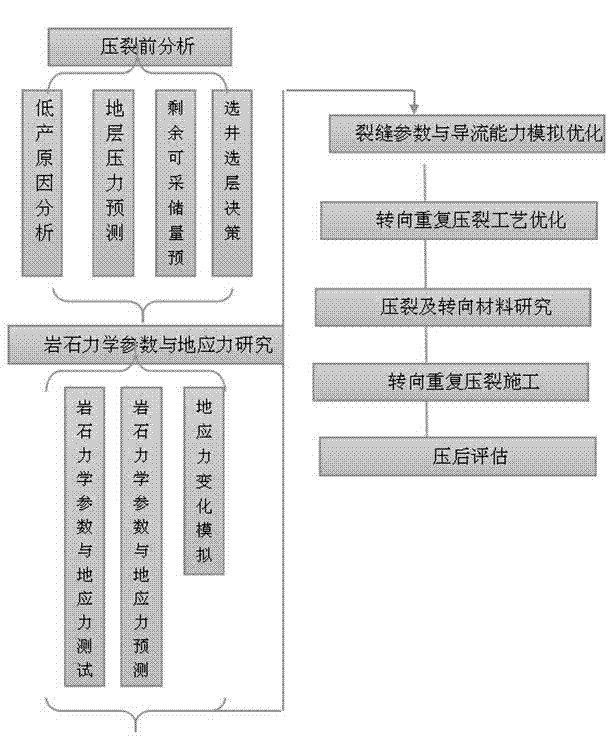

[0031] Such as figure 1 As shown, the process consists of three parts: pre-fracture analysis and evaluation, modeling and simulation, and fracturing construction:

[0032] (1) Pre-f...

Embodiment 2

[0046] The remaining recoverable reserves of a single well evaluated before fracturing in the above embodiment are verified by remaining gas detection. The remaining gas detection is carried out using gas saturation logging before repeated stimulation. If the remaining gas detection results are consistent with the pre-fracturing evaluation results, proceed to the next step , if they do not match, the detection results shall prevail, and the prediction model shall be corrected to improve the accuracy of the model.

[0047] In the fracturing construction step, while turning to repeated fracturing construction, the microseismic technology is used to monitor the initiation, extension, and turning of new fractures, and to verify the previous research results and fracturing design results. If the results are consistent, proceed to the next step. If not Based on the detection results, the prediction model is corrected to improve the accuracy of the model.

[0048] The steps to esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com