A kind of silicon dioxide/cellulose magnetic foam and its preparation method

A technology of silica and magnetic foam, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., to achieve the effects of light weight, large oil absorption, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

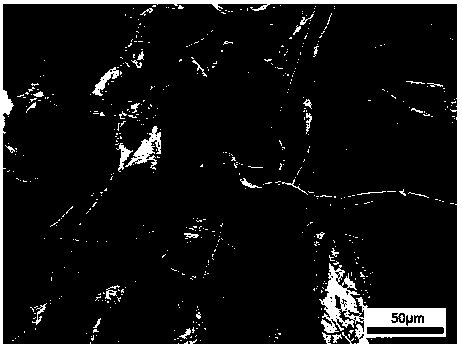

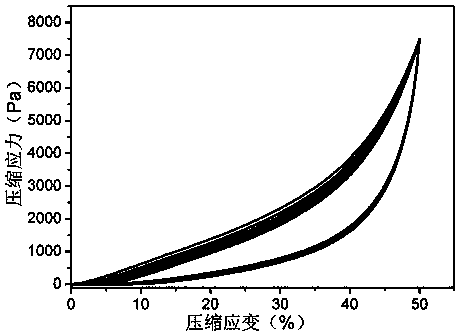

[0040] (1) Weigh 250 mg of silica fiber and 250 mg of fibrillated cellulose, add 100 ml of deionized water, and stir for 3 hours with a high-speed mixer at a speed of 2000 rpm to fully mix the silica fiber and cellulose Disperse to form a silica fiber / cellulose mixed solution; add 25 microliters of glutaraldehyde and 500 mg of ferric oxide nanoparticles to the mixed solution, use a glass stirring rod to continue stirring at room temperature for 2 hours, and then place in an ice bath Ultrasound for 2 hours to fully disperse the nanoparticles; adjust the pH of the system to 5 with dilute sulfuric acid, and cross-link the mixed solution at 75°C for 3 hours to obtain a mixed solution hydrogel; freeze the obtained hydrogel at -80°C After 6 hours, the moisture in the gel was removed by freeze-drying to obtain a three-dimensional foam material.

[0041] (2) Seal the obtained three-dimensional foam and 5 microliters of tridecafluorooctyltriethoxysilane coupling agent in a glass dish, ...

Embodiment 2

[0046](1) Weigh 250 mg of silica fiber and 125 mg of fibrillated cellulose, add 60 ml of deionized water, and stir for 2 hours at a speed of 3000 rpm with a high-speed mixer to fully mix the silica fiber and cellulose Disperse to form a silica fiber / cellulose mixed solution; add 34 microliters of glutaraldehyde and 187.5 mg of ferric oxide nanoparticles to the mixed solution, use a glass stirring rod to continue stirring at room temperature for 1 hour, then place in an ice bath Ultrasound for 1 hour to fully disperse the nanoparticles; adjust the pH of the system to 5.5 with dilute sulfuric acid, and cross-link the mixed solution at 60°C for 2 hours to obtain a mixed solution hydrogel; freeze the obtained hydrogel at -50°C After 10 hours, the water in the gel was removed by freeze-drying to obtain a three-dimensional foam material.

[0047] (2) Seal the obtained three-dimensional foam and 37.5 microliters of tridecafluorooctyltrimethoxysilane coupling agent in a glass dish, pl...

Embodiment 3

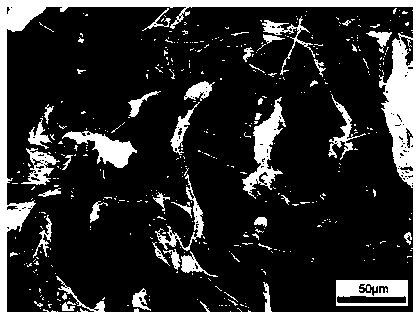

[0053] (1) Weigh 250 mg of silica fiber and 500 mg of fibrillated cellulose, add 75 ml of deionized water, and stir for 1 hour at a speed of 5000 rpm with a high-speed mixer to fully mix the silica fiber and cellulose Disperse to form a silica fiber / cellulose mixture. Add 340 microliters of 50wt% glutaraldehyde aqueous solution and 1500 mg of ferric oxide nanoparticles to the mixed solution, use a glass stirring rod to continue stirring at room temperature for 3 hours, and then ultrasonically disperse the nanoparticles in an ice bath for 3 hours; The pH value of the system was adjusted to 4.5 by dilute sulfuric acid, and the mixed solution was cross-linked at 80°C for 4 hours to obtain the mixed solution hydrogel; the obtained hydrogel was frozen at -50°C for 10 hours, and then the gel was freeze-dried Moisture is removed to obtain a three-dimensional foam.

[0054] (2) Seal the obtained three-dimensional foam and 70 microliters of tridecafluorooctyltrimethoxysilane coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com