High luster aqueous anticorrosion paint for engineering machinery chassis and its preparation method

A technology for engineering machinery and anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of energy pollution, waste of solvents, low gloss, etc., and achieve excellent corrosion resistance, good scratch resistance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

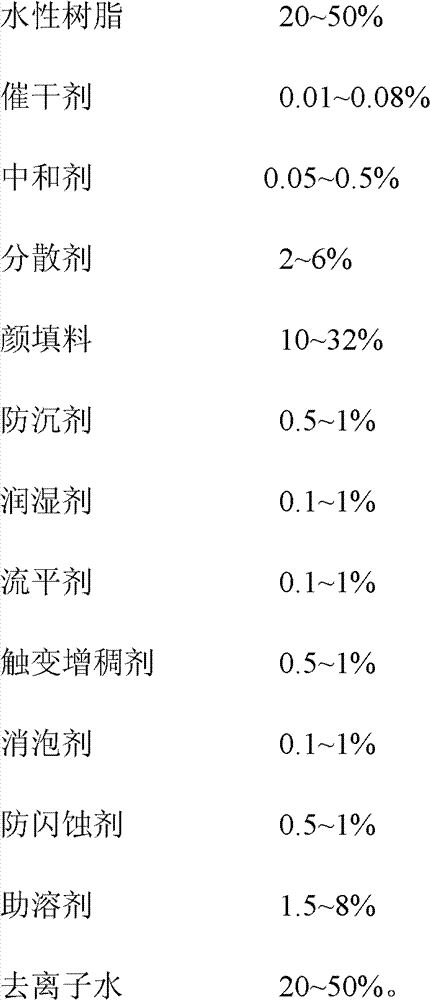

Method used

Image

Examples

Embodiment Construction

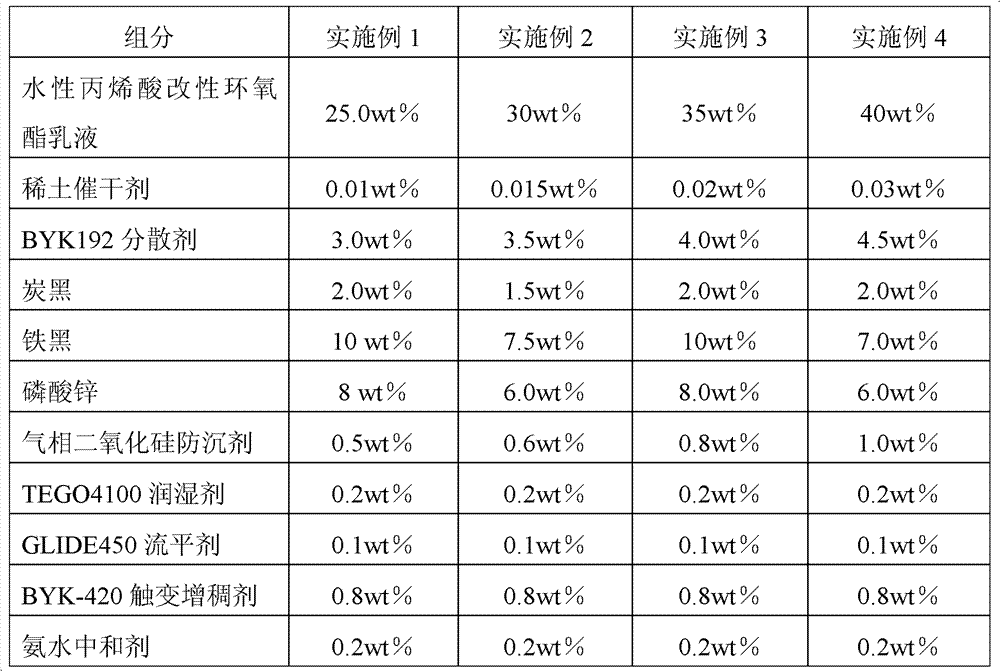

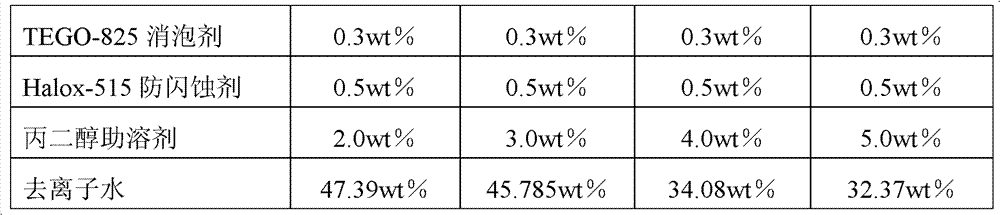

[0032] Some specific examples are listed below to illustrate the present invention. It should be pointed out that the following specific examples are only used to further illustrate the present invention, and do not represent limitations to the protection scope of the present invention. Some non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

[0033] Examples 1-4 Refer to Table 1 for the composition of water-based anti-corrosion coatings for construction machinery chassis. The preparation method is as follows: add part of the water-based resin to the stirring tank, add a dispersant, add pigments, fillers and anti-settling agents during the stirring process, and disperse for 20 minutes until the dispersion is complete. Evenly, the temperature is controlled below 50 degrees, and then sanded to a fineness below 15um. Then add wetting agent, leveling agent, thixotropic thicken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com