Method for testing aging degree of transformer oil

A technology of aging degree and testing method, which is applied in the direction of using chemical indicators for analysis and titration for chemical analysis, etc. It can solve problems such as strong irritation, benzene toxicity, and changes in the hematopoietic system of benzene, and achieve good consistency and operation. Convenience, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

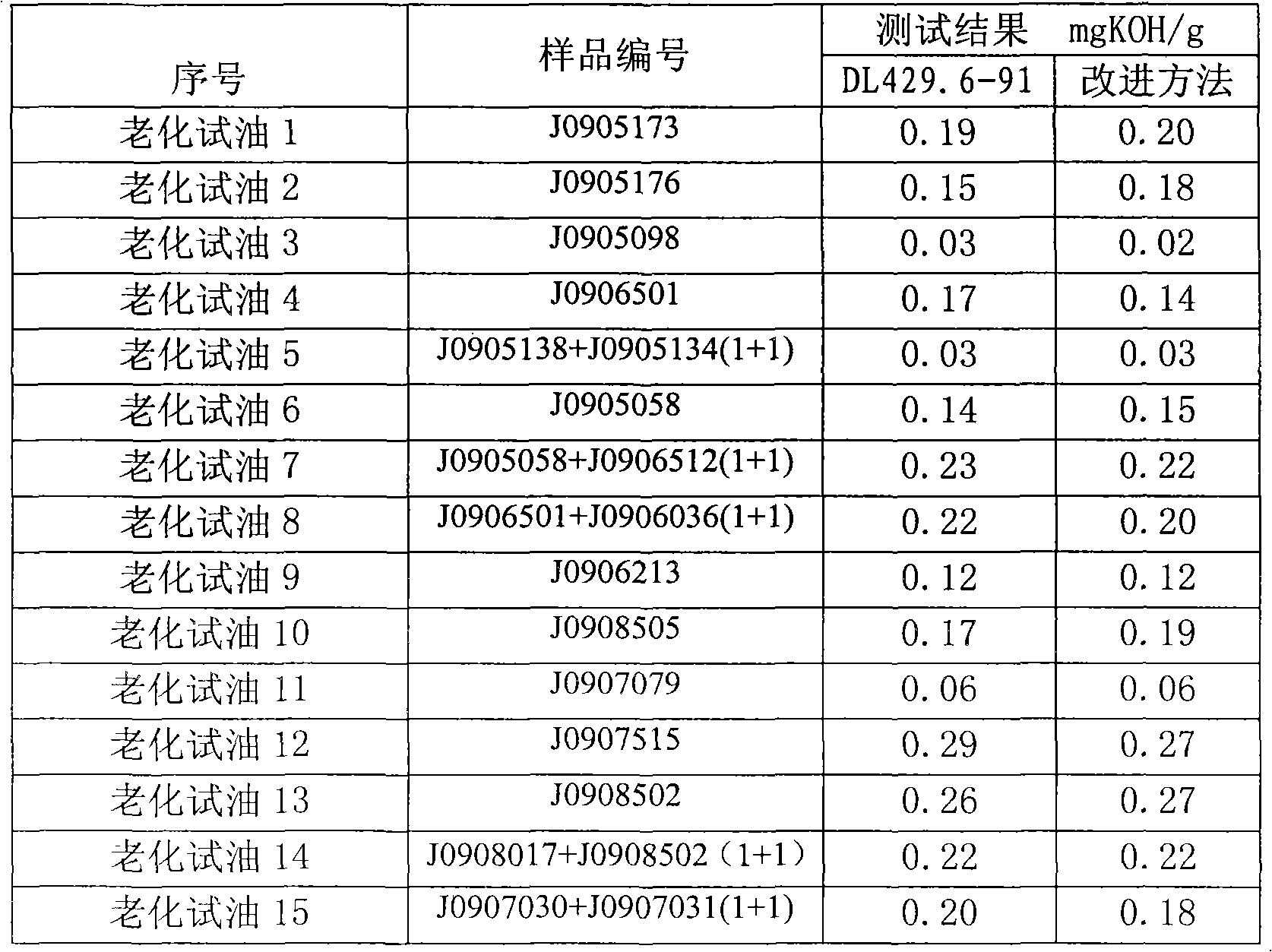

Examples

Embodiment Construction

[0023] A method for testing the aging degree of transformer oil, which comprises the following steps:

[0024] 1).Oil sample test

[0025] Accurately weigh 5.0-10.0g of the aged test oil, add 50ml of ethanol-petroleum ether mixture, shake well, then add 0.5ml of basic blue 6B indicator, and titrate with 0.05mol / L KOH ethanol solution until the color of the mixed solution is until it becomes light red;

[0026] 2).Blank solvent test

[0027] Measure 50ml of ethanol-petroleum ether mixture, and perform blank measurement according to the same operation as above;

[0028] 3). Calculation

[0029] 3. The formula for calculating the acid value of test oil after aging is as follows:

[0030] c(mgKOH / g)=(V-V1)*C1*56.1 / m

[0031] in

[0032] c: acid value, mgKOH / g

[0033] V: Volume of 0.05mol / L potassium hydroxide ethanol solution sample consumed when titrating test oil, ml

[0034] V1: When titrating the blank solution, the volume of 0.05mol / L potassium hydroxide ethanol solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com