Ester glycosyl phase selective oleophylic gelator as well as preparation method and application thereof in oil gelatinization

A selective, oil-gel technology, applied in separation methods, carboxylic acid halide preparation, grease/oily substance/suspton removal devices, etc., can solve problems such as high cost, cumbersome preparation process, and slow gelation rate. Achieve high-efficiency gelling ability, overcome the cumbersome preparation process, and achieve the effect of high-efficiency oil-water separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

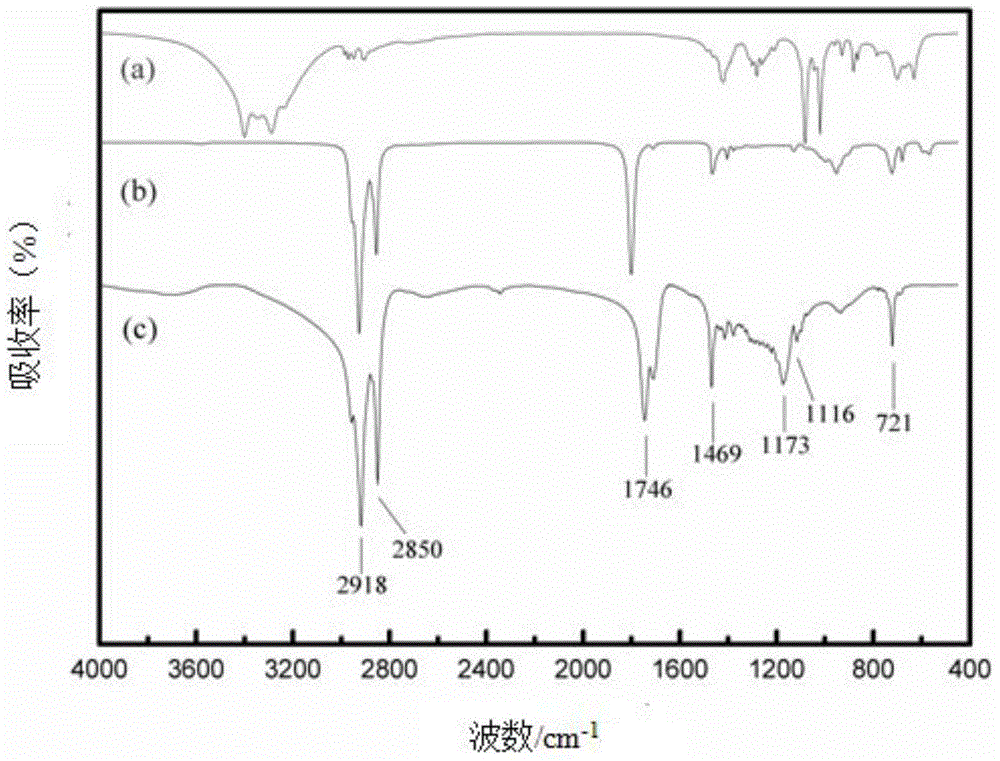

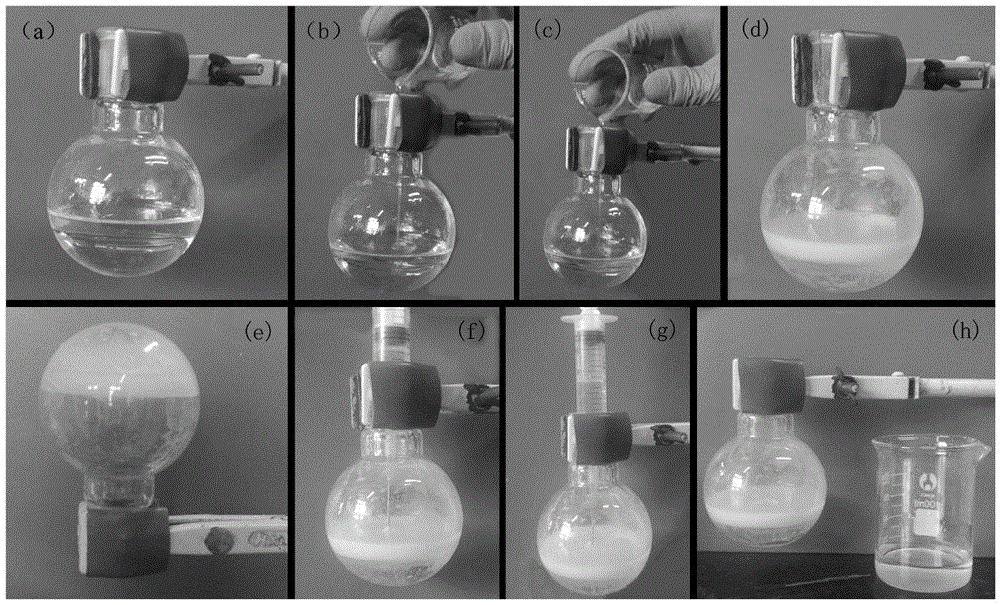

[0024] (1) Weigh 2.00 g of mannitol into a four-neck flask, add 20 ml of dichloromethane as a solvent, and stir at high speed for 1 hour to fully disperse it.

[0025] (2) Put the four-neck flask in an ice bath, add 0.40 g of acid-binding agent triethylamine and dropwise add 6.65 g of stearyl chloride while keeping stirring. After the stearyl chloride was added dropwise, the reaction was continued for 0.5 hours in an ice bath. Then start to raise the temperature in stages: after raising the temperature to 60°C, keep the temperature for 1 hour, continue to raise the temperature to 75°C, keep the temperature for 3.5 hours, continue to raise the temperature to 95°C, keep the temperature for 3 hours, and then stop the reaction.

[0026] (3) The product obtained in step (2) was evaporated to remove the solvent with a rotary evaporator under reduced pressure, and then 30ml of hot distilled water and 45ml of ethyl acetate were added to wash, left to stand, layered, and separated to o...

Embodiment 2

[0029] (1) Weigh 2.00 g of mannitol into a four-neck flask, add 20 ml of solvent toluene, and stir at high speed for more than 1 hour to fully disperse it.

[0030](2) Put the four-neck flask in an ice bath, add 0.40 g of acid-binding agent triethylamine and dropwise add 6.65 g of stearyl chloride while keeping stirring. After the stearyl chloride was added dropwise, the reaction was continued for 1 hour in an ice bath. Then start to raise the temperature in stages: after raising the temperature to 60°C, keep the temperature for 1 hour, continue to raise the temperature to 75°C, keep the temperature for 4 hours, continue to raise the temperature to 95°C, keep the temperature for 3.5 hours, and then stop the reaction.

[0031] (3) The product obtained in step (4) was evaporated to remove the solvent with a rotary evaporator under reduced pressure, then added 30ml of hot distilled water and 45ml of ethyl acetate to wash, left to stand, layered, and separated to obtain an ethyl a...

Embodiment 3

[0034] (1) Weigh 2.00 g of mannitol into a four-neck flask, add 20 ml of solvent N,N-dimethylformamide, and stir at high speed for more than 1 hour to fully dissolve it.

[0035] (2) Put the four-neck flask in an ice bath, add 0.40 g of acid-binding agent triethylamine and dropwise add 6.65 g of stearyl chloride while keeping stirring. After the stearyl chloride was added dropwise, the reaction was continued for 0.5 hours in an ice bath. Then start to raise the temperature in stages: after raising the temperature to 60°C, keep the temperature for 1 hour, continue to raise the temperature to 75°C, keep the temperature for 4 hours, continue to raise the temperature to 95°C, keep the temperature for 3.5 hours, and then stop the reaction.

[0036] (3) The product obtained in step (2) was evaporated to remove the solvent with a rotary evaporator under reduced pressure, and then 30ml of hot distilled water and 45ml of ethyl acetate were added to wash, left to stand, layered, and sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com