A method and system for treating waste kitchen waste oil

A technology of waste oil and treatment method, which is applied in the direction of recovery of fat oil/fatty acid from waste, production of fat, and recovery of fatty substances. It can solve the problems of large pollution, high water content, low yield and purity of finished products, and achieve high output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

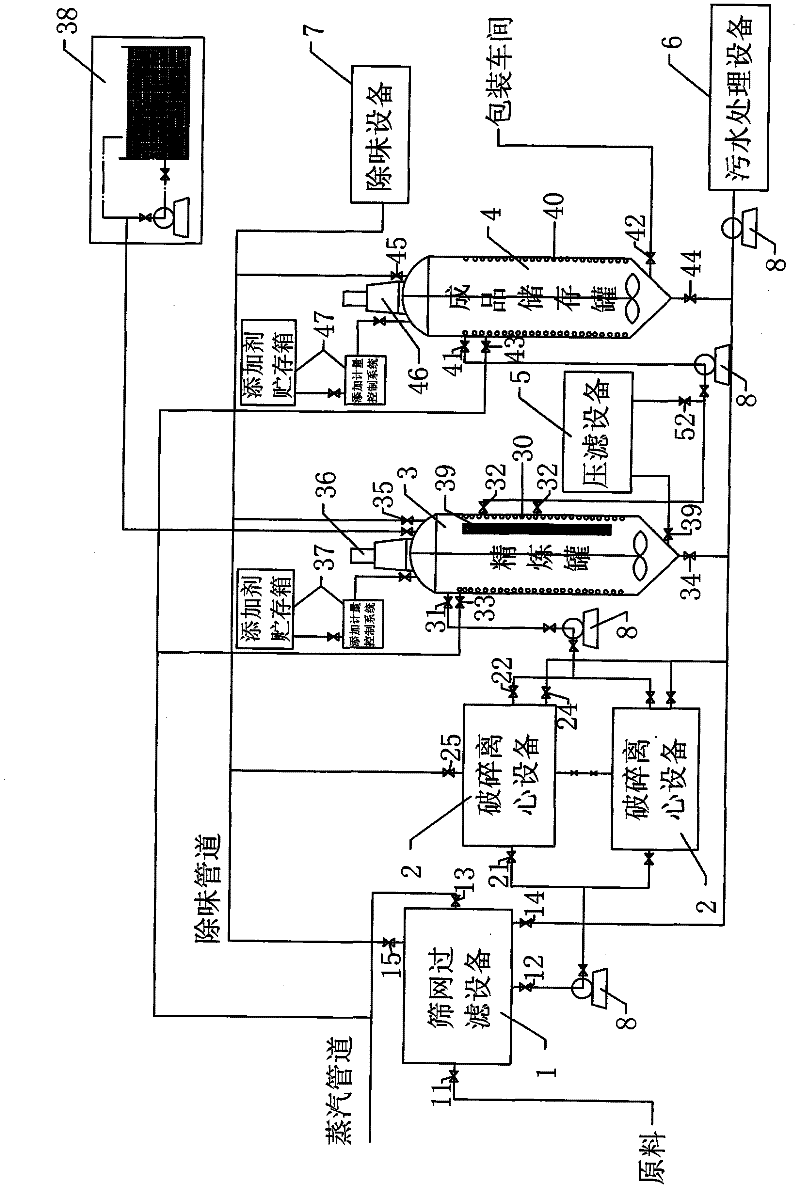

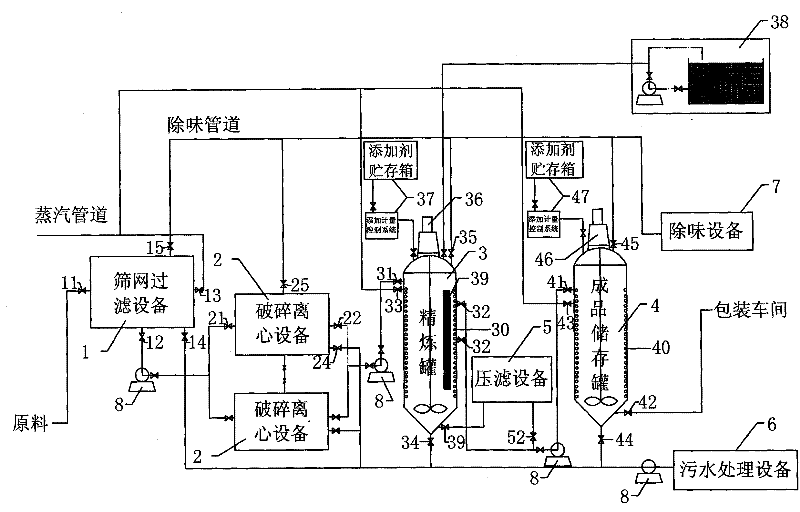

[0033] An embodiment of the refining of kitchen waste and waste oil provided by the present invention will be described in detail below.

[0034] In this embodiment, the implementation of a kitchen waste oil treatment process mainly includes the following steps:

[0035] In the sieve filtration step, the recovered kitchen waste oil is filtered through a sieve at a temperature of 40-50°C to initially remove impurities:

[0036] The existing kitchen waste oil treatment process basically does not pretreat the raw materials recovered from the production unit, but directly produces and processes them after entering the factory, because the kitchen waste oil contains a lot of vegetables, meat, rice, etc. , pasta and other residues, and some even contain diverse impurities such as towels, plastic packaging bags, tableware fragments, etc., so that the existing technology consumes a lot of energy in the process of processing kitchen waste and waste oil, and the lipophilic impurities an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com