Isomerization process using metal-modified small crystallite mtt molecular sieve

a technology of molecular sieve and small crystallite, which is applied in the direction of catalytic naphtha reforming hydrocarbon oil treatment, etc., can solve the problem that none of the processes produced a molecular sieve with a small crystallite siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Small Crystallite MTT Molecular Sieve

[0092]Small crystallite MTT molecular sieve was synthesized as follows: A Hastelloy C liner for a 5 gallon autoclave unit was used for the mixing of reagents and then in the subsequent thermal treatment. At a rate of 1500 RPM and for a period of ½ hour, the following components were mixed once they had been added in the order of description. 300 grams of a 1 Molar solution of N,N′ Diisopropyl imidazolium hydroxide was mixed into 4500 grams of water. The salt iodide was prepared as in U.S. Pat. No. 4,483,835, Example 8, and then subsequently was ion-exchanged to the hydroxide form using BioRad AG1-X8 exchange resin. 2400 grams of 1 N KOH were added. 1524 grams of Ludox AS-30 (30 wt % SiO2) were added. 1080 grams of Nalco's 1056 colloid sol (26 wt % SiO2 and 4 wt % Al2O3) were added. Last 181 grams of isobutylamine were stirred into the mixture. The rfiolar concentration of the amine Qb exceeded the molar concentration of the imidazo...

example 2

[0095]The product of Example 1 was calcined to 1100° F. in air with a ramp of 1 deg. C. / min (1.8 F / min)and plateaus of 250° F. for 3 hours, 1000 F for 3 hours and then 1100° F. for 3 hours. The calcined material retained its;x-ray crystallinity. The calcined zeolite was subjected to 2 ion-exchanges at 200° F. (using NH4 NO3) as has been previously described in U.S. Pat. No. 5,252,527. The ion-exchanged material was recalcined and then the microporosity measurements were explored, using a test procedure also described in U.S. Pat. No. 5,252,527. The new product, small crystallite MTT molecular sieve, had some unexpected differences vs. conventional SSZ-32.

[0096]The Ar adsorption ratio for small crystallite MTT molecular sieve (Ar adsorption at 87K between the relative pressures of 0.001 and 0.1) / (total Ar adsorption up to relative pressure of 0.1) is larger than 0.5. In one embodiment the Ar adsorption ratio is in the range of 0.55. to 0.70. In contrast for the conventional SSZ-32, t...

example 3

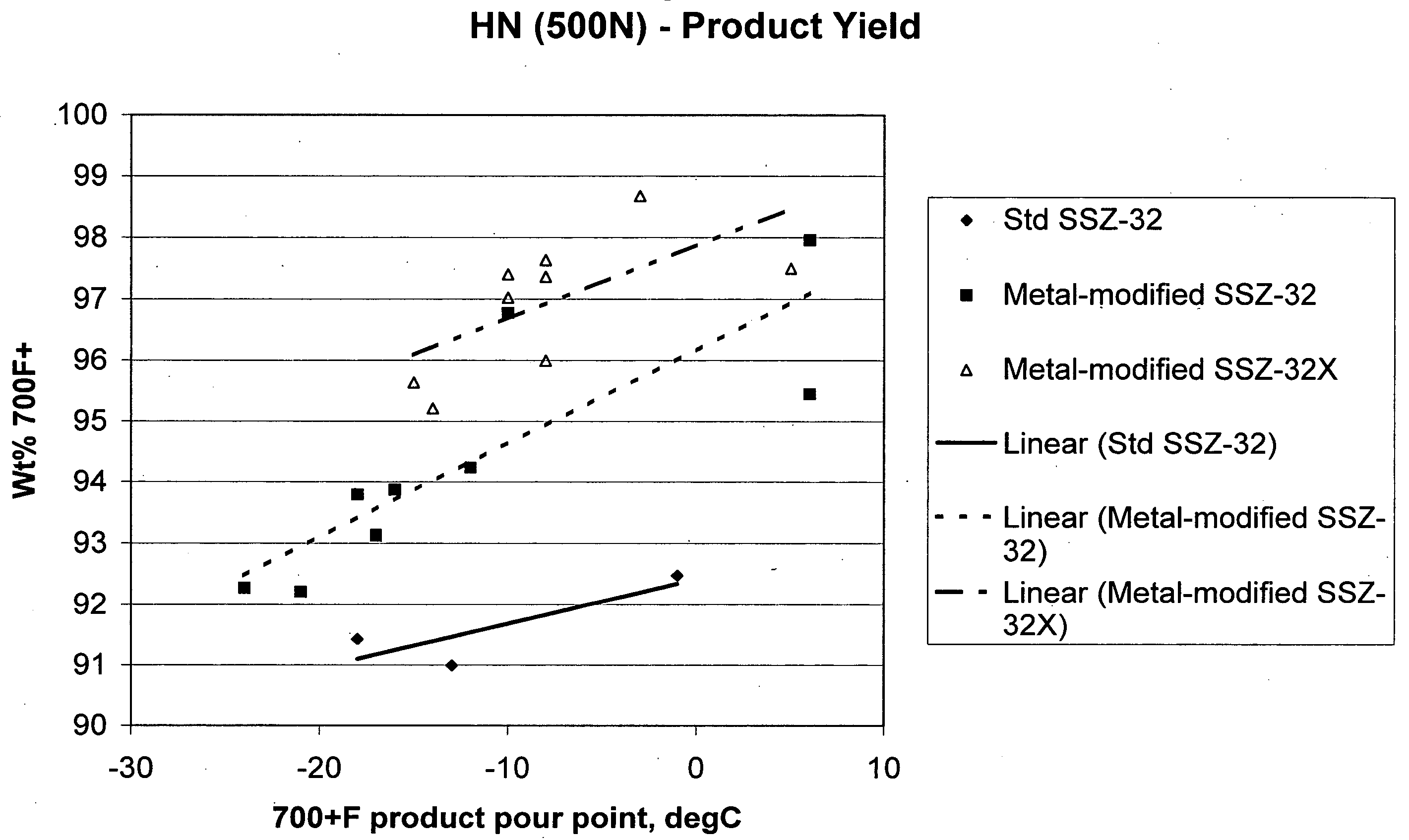

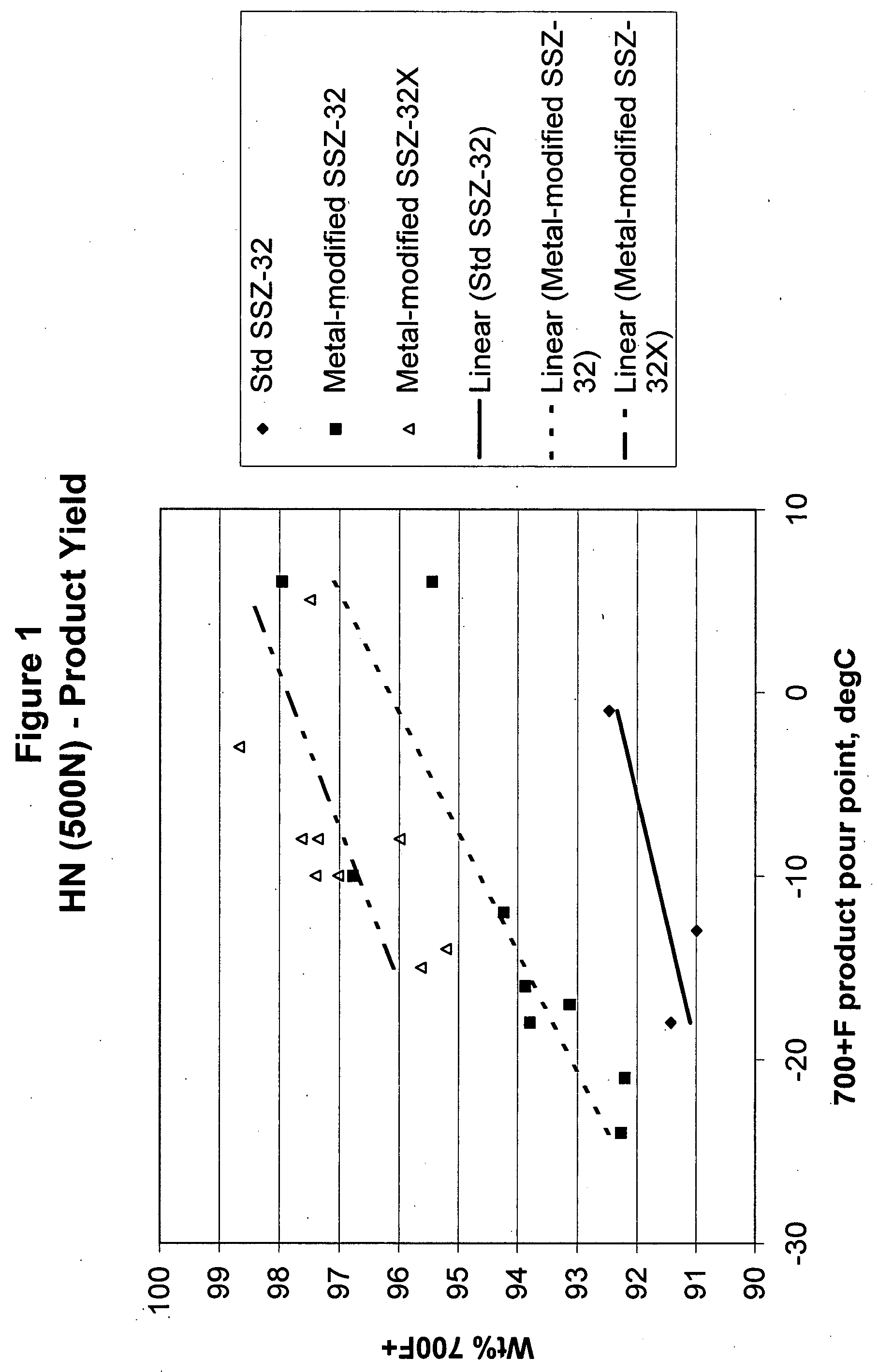

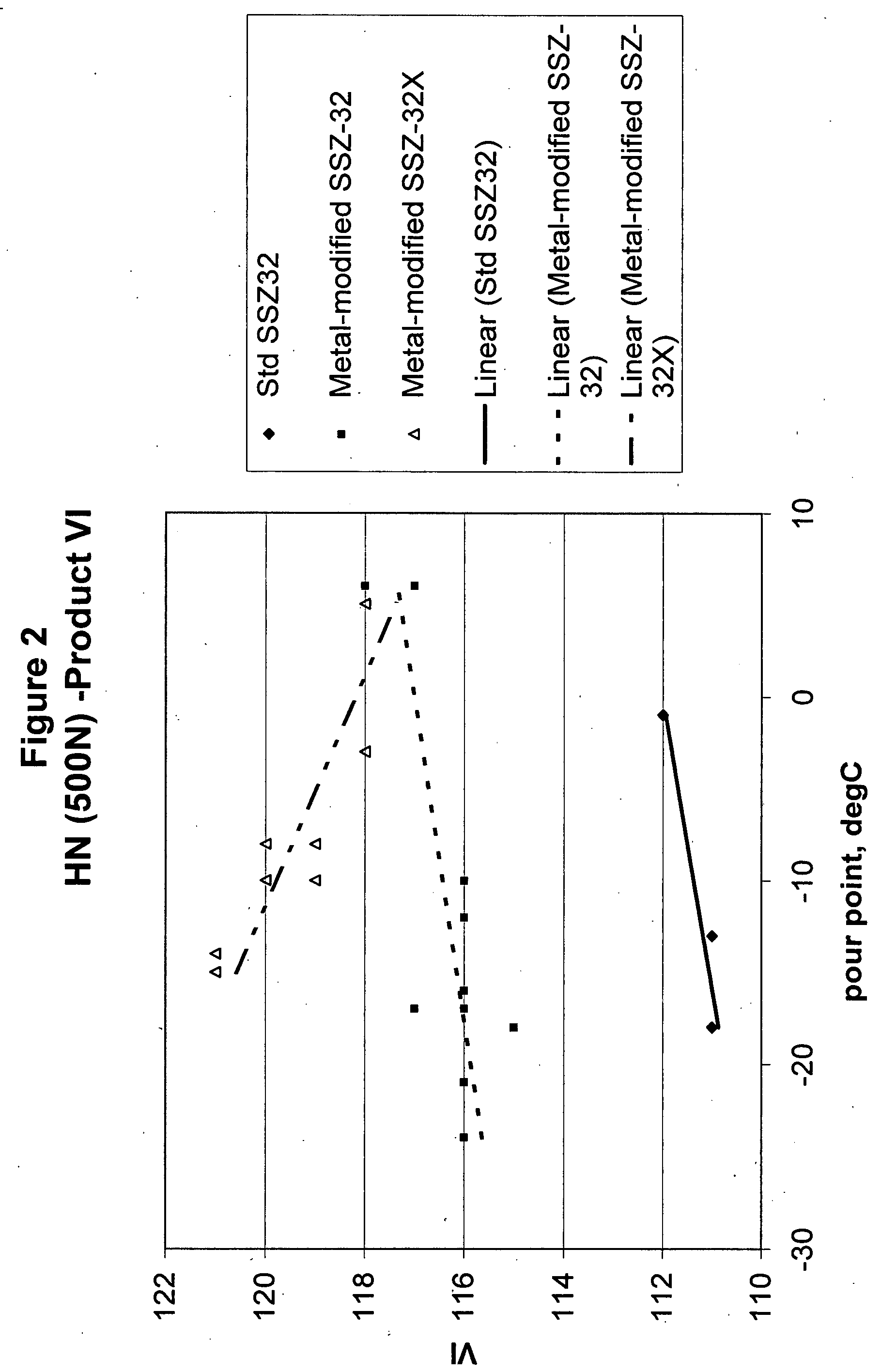

[0098]Small crystallite MTT zeolite was composited with alumina, extruded, dried, and calcined. The dried and calcined extrudate was impregnated with a solution containing both platinum and magnesium, and then finally dried and calcined. The overall platinum loading was 0.325 wt. %. This metal-modified catalyst was then tested for isomerization on a waxy 500N hydrocrackate feed having 21% wax, a kinematic viscosity at 100° C. of 10.218 mm2 / s, and a pour point of +51° C. Isomerization process conditions used were a LHSV of 1.0 hr−1, 4000 scf / bbl gas to oil ratio, and a total pressure of 2300 psig. Following isomerization the products were hydrofinished over a Pt / Pd silica alumina hydrofinishing catalyst at 450° F. The VI of the waxy 500N hydrocrackate feed was 122, and the VI of the solvent dewaxed waxy 500 hydrocrackate feed was 106 when solvent dewaxed at −18° C. The difference between the waxy VI and the catalytic isomerized product VI was only two (122-120), which was exceptional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallite diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com