Lubricant and additive formulation

a technology of additives and lubricants, applied in the field of additives, can solve the problems of unpopular use of graphite in lubricants for recirculating systems, inability to realize the potential to use graphite as a heat transfer improving material in this oil, and inability to improve the thermal conductivity of fluid formulations specific to specific applications. , to achieve the effect of enhancing the performance of the engine, reducing engine wear, and improving the lubricating properties of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

The Invention of Example 1 Under Standard Tests

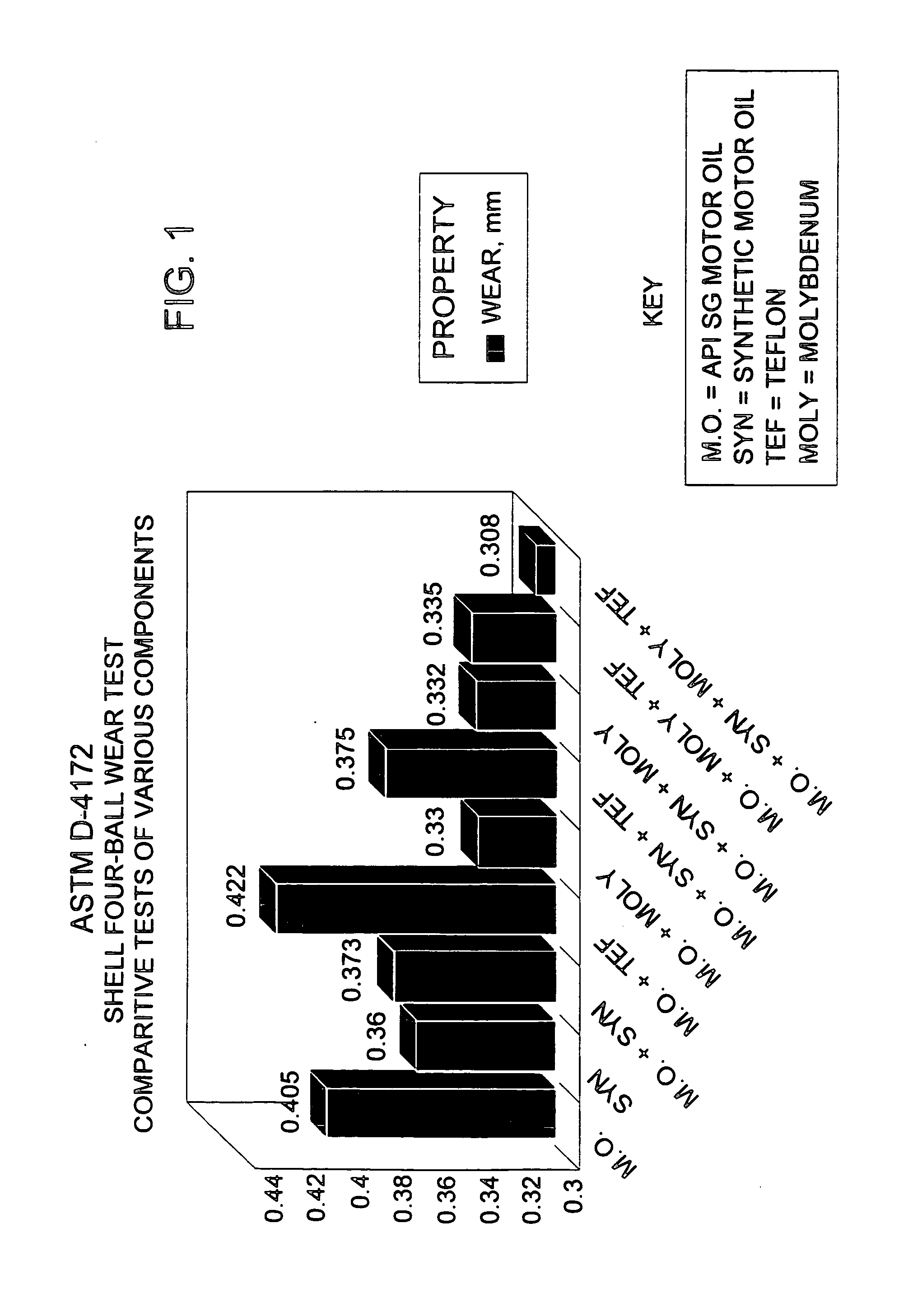

[0153] When one of the one quart formulations prepared in Example 1 is tested under conventional lubricant test procedures, results are as given in Tables 1 and 2, and FIGS. 1-5. Note that the Shell four-ball wear test ASTM D4172 of FIG. 1 and Table 1 is a bench test indicative of wear performance of a lubricant.

[0154] When the same ingredients of Example 1 are formulated while omitting one or more of the ingredients, the comparative results are as shown in Table 1 and FIG. 1.

TABLE 1ASTM 4172 Shell Four BallAC +AC +AC +AC + SYN +AC +AC +AC +SYN +SYN +MOLY +MOLY +TESTACSYNSYNTEFMOLYTEFMOLYTEFVI + DI*Shell0.4050.3600.3730.4220.3300.3750.3320.3350.308Four-BallWear,mm

MO Motor Oils, VALVOLINE 10W30 All-Climate

SYN VALVOLINE 5W30 Synthetic, includes DI and VI

AC + SYN 10W30 AC + (20%) 5W30 Synthetic

MOLY Molybdenum

TEF TEFLON ®

example 1

ADDITIVE Invention of Example 1

[0155]

TABLE 2ASTM 4742 - 88 OxidationRFOUTTFOUTCCS@20NCTP1@20NFSample(min)**(min)*Ruler***cPcPA1801382113,03012,540C3702793222,1609,360

Note:

A 10W30 All Climate (Motor Oil Control)

*C 80% Control plus 20% Additive

**Thin Film Oxygen Uptake

***Modified test of ASTM 4742

Remaining useful Life Evaluation Routine

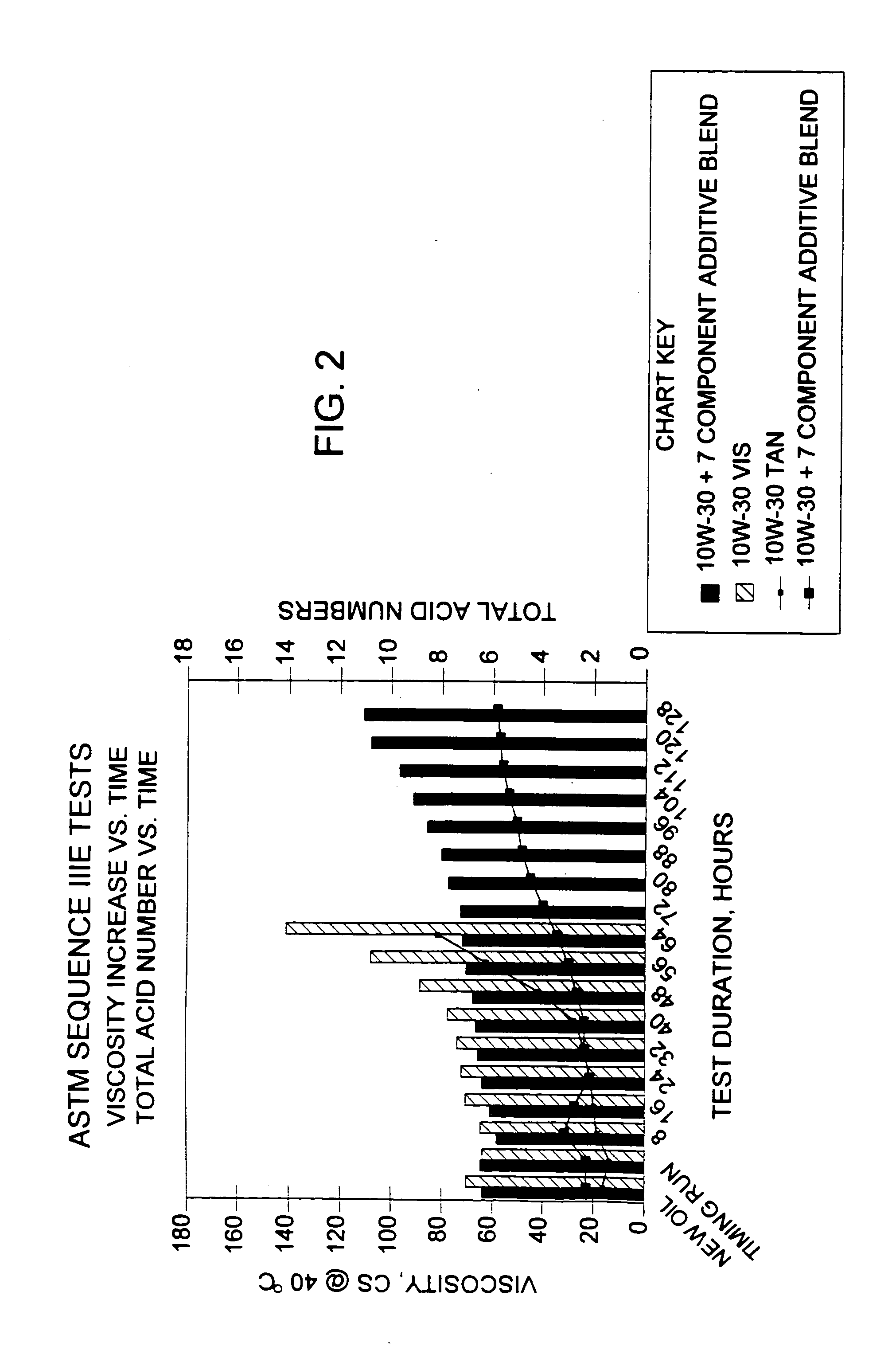

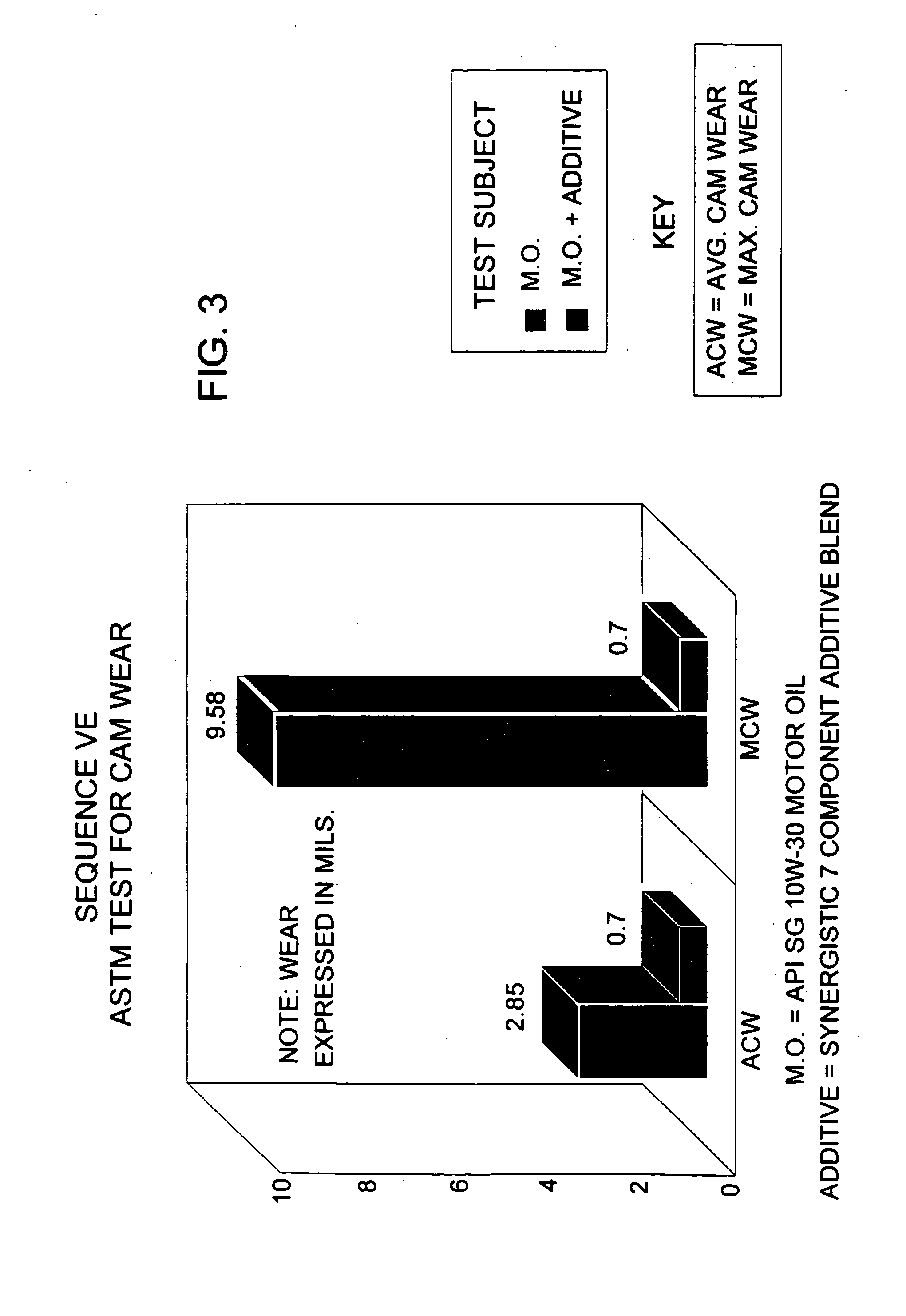

[0156] As can be seen from Tables 1 and 2, and FIGS. 1 through 5, the results using this additive show a remarkable improvement when compared to a conventional motor oil tested without the additive of the invention.

example 3

[0157] A grease composition according to the invention of Example 1 can be conventionally mixed with a lithium soap of a fatty acid to thicken the composition and to result in an improved grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com