Lubricating-oil composition of speed reducing machine in gas turbine for ship

A lubricating oil composition and technology for gas turbines, applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the problems that there is no standard for large-scale gas turbine lubricating oil for ships, and achieve superior low-temperature fluidity, good thermal stability, and good Antioxidant effect

Inactive Publication Date: 2013-10-30

GUANGXI UNIV

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the continuous development of gas turbine technology in my country, especially after the introduction of UGT25000 gas turbine technology from Ukraine and the recent introduction of GE's LM2500+G4 series technology for the construction of power stations, the use of gas turbines on ships has become an inevitable development of ship power. There is a growing demand for localized supporting facilities; however, the development of lubricating oil for reducers in marine gas turbines is still a weak point in China, and there is no lubricating oil standard for large gas turbines for ships.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

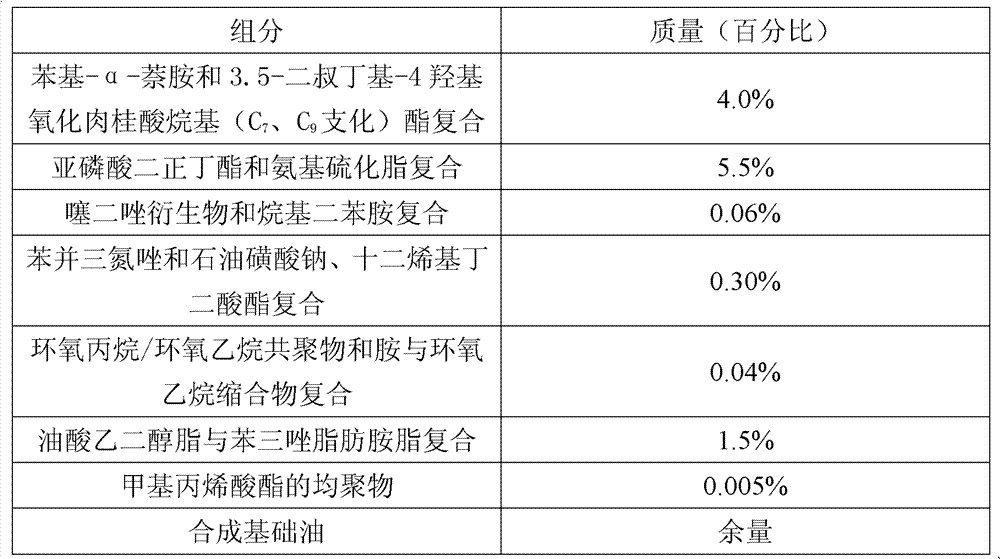

Embodiment 1

[0020]

[0021] The sum of the above components is 100%.

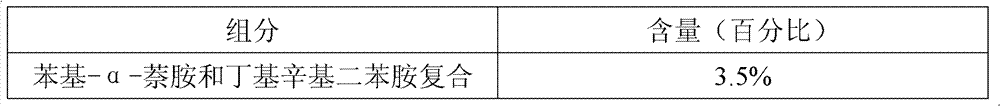

Embodiment 2

[0023] Blend the following components by mass percentage:

[0024]

[0025]

[0026] The sum of the above components is 100%.

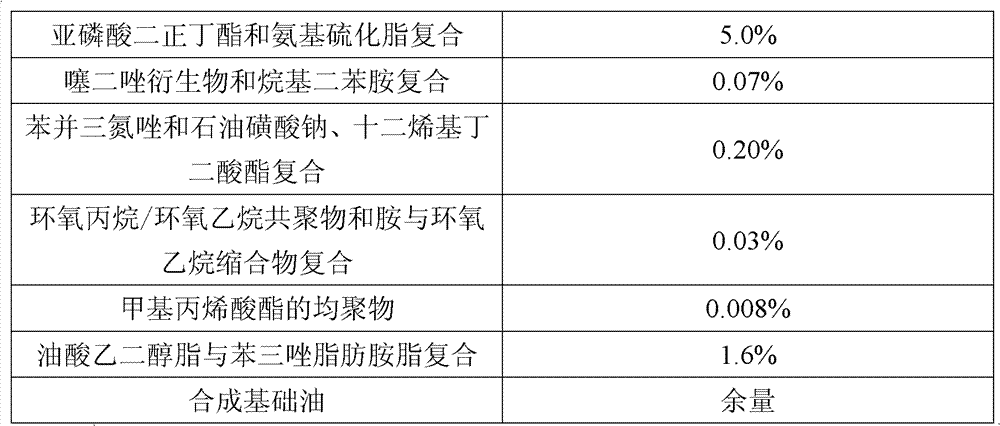

Embodiment 3

[0028] The following components by weight percentage are reconciled and made:

[0029]

[0030] The sum of the above components is 100%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a lubricating-oil composition of a speed reducing machine in a gas turbine for ship. The lubricating-oil composition comprises the following components in percent by mass: 2-4% of antioxidant, 5-6% of antiwear agent, 0.1-0.4% of antirusting agent, 0.06-0.08% of metal passivating agent, 0.05-0.3% of demulsifying agent, 0.005-0.01% of anti-foaming agent, 1-2% of oiliness agent and the balance of base oil. The lubricating-oil composition has the obvious advantages that the comprehensive performance is good, and all performance indexes meet the use requirements; not only are the antioxygen, anticorrosion and antiwear performances good, but also the antirusting, anti-salt-fog and antifoaming performances are quite excellent; the lubricating-oil composition also meet the use requirements of the gas turbine for ship in the aspects of acid control capability, clean dispersity and rubber adaptability; and the base oil is compounded and synthesized by selecting diester and polyol ester which have excellent performance, so that the base oil assuredly has good heat stability, good viscosity-temperature characteristic, excellent low-temperature mobility, low volatility and good lubricity simultaneously.

Description

technical field [0001] The invention relates to a lubricating oil composition for a reducer in a marine gas turbine. Background technique [0002] With the continuous development of gas turbine technology in my country, especially after the introduction of UGT25000 gas turbine technology from Ukraine and the recent introduction of GE's LM2500+G4 series technology for the construction of power stations, the use of gas turbines on ships has become an inevitable development of ship power. However, the development of lubricating oil for reducers in marine gas turbines is still a weak point in China, and there is no lubricating oil standard for large gas turbines in ships. Therefore, it is of great significance to develop lubricating oil for marine gas turbine reducer. [0003] At present, the lubricating oil system of marine gas turbines in my country is mainly divided into two parts, front and rear, which are designed independently. This is because the front part of the gas gen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M169/04C10M111/04C10N30/10C10N30/12C10N30/06C10N30/18C10N30/04C10N40/12

Inventor 黄福川卢朝霞莫宇飞梁景粟满荣唐兴中谢云果杨茂立李宏君田宗义蓝明新

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com