Crown gear central differential lubricant composition

A lubricant composition, the technology of the central differential, applied in the directions of the lubricant composition, the petroleum industry, etc., can solve the problems of increasing the non-slip torque, etc., and achieve the effects of reducing wear, providing vibration, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

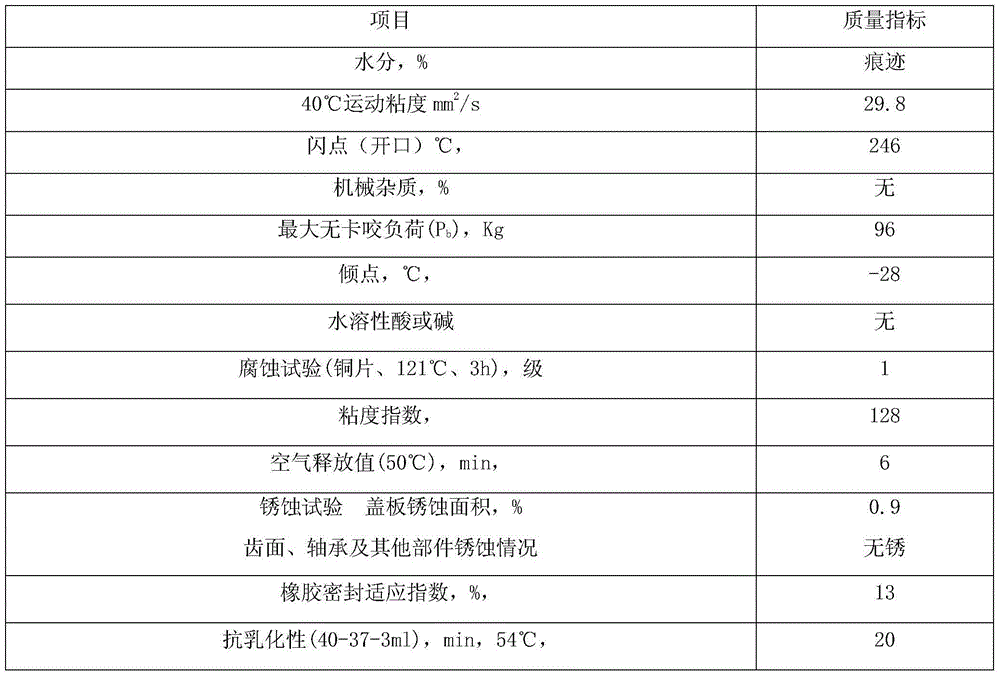

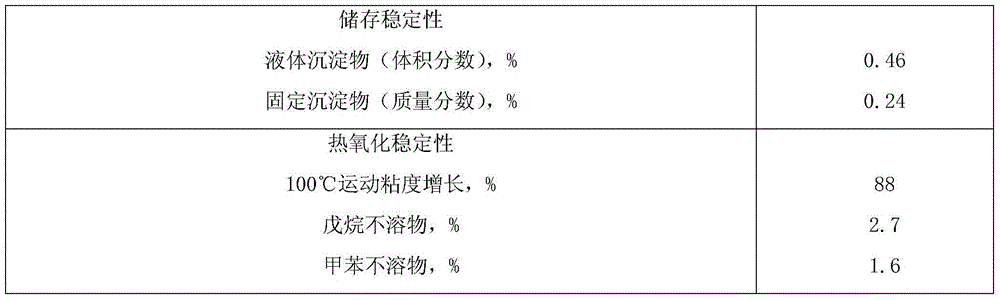

Embodiment 1

[0018] It is formed by blending the following components in mass percentage:

[0019] components

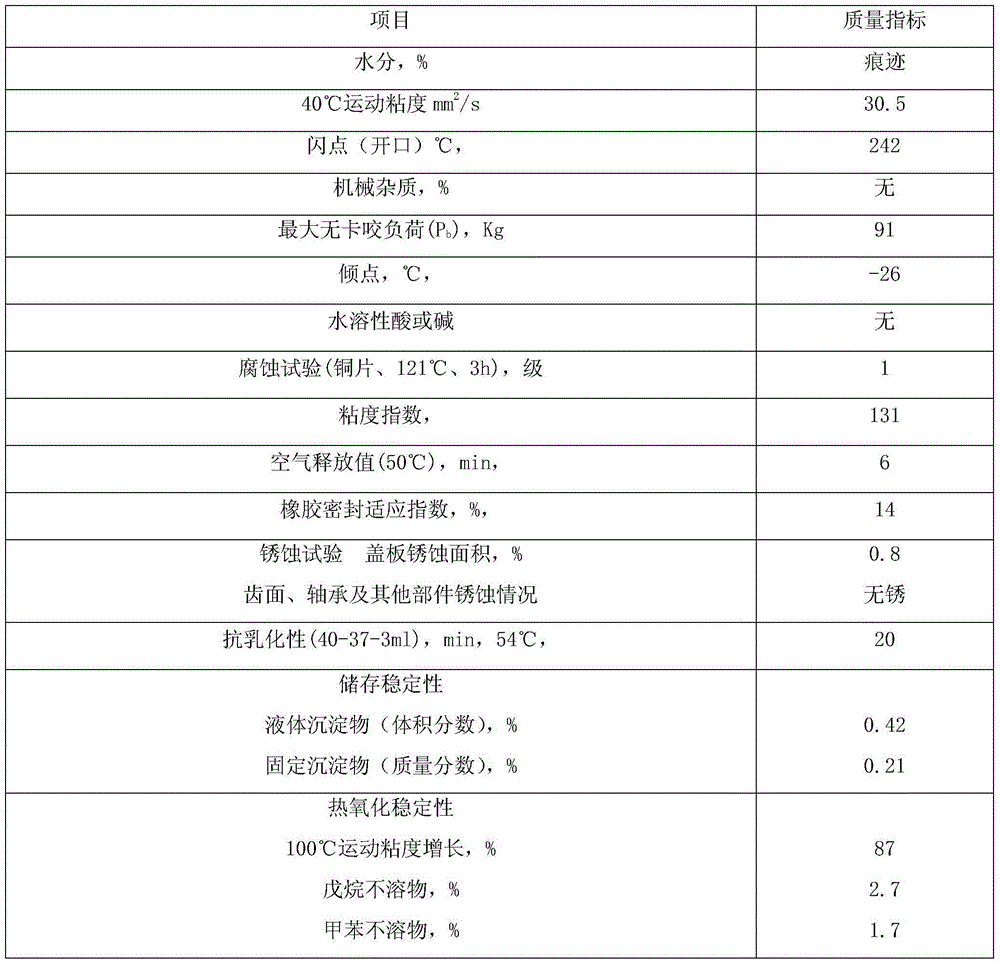

Embodiment 2

[0020] Embodiment 2: each component of following mass percentage is reconciled and forms:

[0021] components

Embodiment 3

[0023] It is formed by blending the following components in mass percentage:

[0024] components

Content (mass percentage)

50% polyinternal olefin compounded with 50% diisodecyl sebacate by mass

74.59%

The mass ratio of 50% diisobutyl p-cresol and 50% phenyl-β-naphthylamine composite

1.5%

Combination of 70% sulfurized isobutylene and 30% trimethyl phosphate by mass

8.0%

The mass ratio is 70% sulfurized olefinic cottonseed oil and 30% oleic acid oxalate compound

4.0%

Combination of 50% benzotriazole derivatives and 50% 1,3,4-thiadiazole by mass

1.2%

Alkyl phosphite

2.0%

Benzyl silicone oil

0.01%

Mass ratio of 30% tolyl benzotriazole and 70% sodium petroleum sulfonate composite

1.5%

1.2%

polyalkoxy polyol

1.0%

dienyl succinimide

3.0%

High base value calcium petroleum sulfonate

2.0%

[0025] The main techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com