Tribological design and preparation method of FeNiAlNb-based pin shaft multilayer composite structure material

A multi-layer composite and structural material technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., to achieve outstanding anti-occlusion performance, reduce the impact of frictional surface damage, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

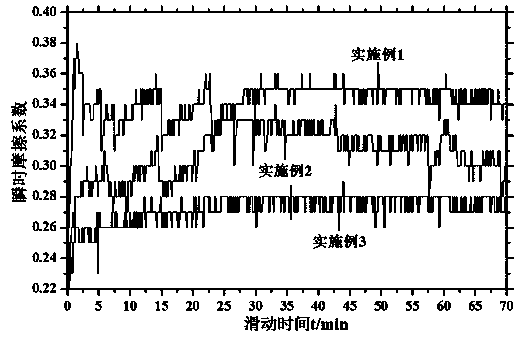

Embodiment 1

[0035] A FeNiAlNb-based pin multi-layer composite structure material is based on FeNiAlNb material as a matrix, friction reducer, anti-wear agent, and reinforcing agent as components, and forms a FeNiAlNb-based pin multi-layer structure, and the structure is divided into friction film, The three-layer composite structure of the bearing transition layer and the base bearing layer, the thickness ratio of each layer is 8:20:72.

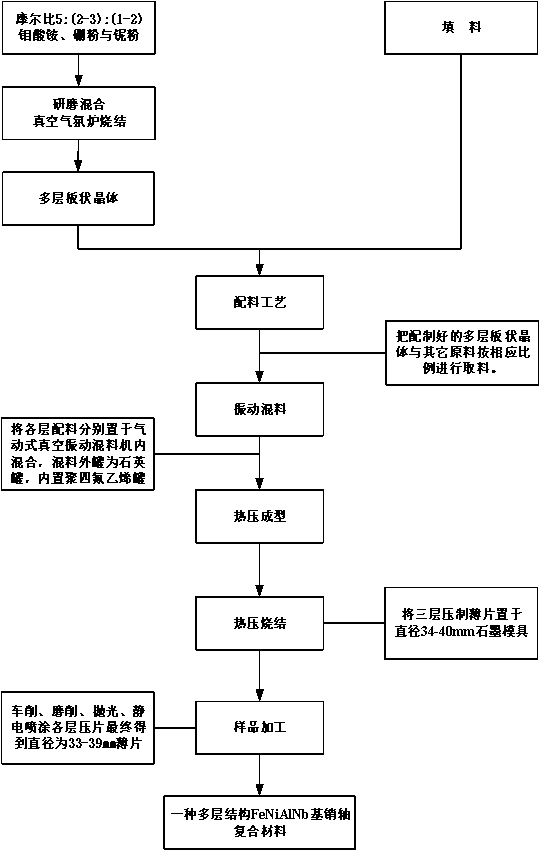

[0036] Such as figure 1 As shown, a kind of FeNiAlNb-based pin shaft multilayer composite structure material tribological design and preparation method thereof specifically comprises the following steps:

[0037] 1) Preparation of multi-layer plate crystal MoBNbO: Weigh ammonium molybdate, boron powder and niobium powder with an average particle size of 35 μm in a molar ratio of 5:2:1, finely grind ammonium molybdate, boron powder and niobium powder with After mixing evenly; then put the powder in a vacuum atmosphere furnace and sinter under argon as a ...

Embodiment 2

[0046] A FeNiAlNb-based pin shaft multi-layer composite structure material is based on FeNiAlNb material as a matrix, friction reducer, anti-wear agent, and reinforcing agent as components, and is compounded layer by layer to form a FeNiAlNb-based pin shaft multi-layer composite structure material, which is divided into The three-layer structure of the friction film, the bearing transition layer and the base bearing layer, the thickness ratio of each layer is 7:33:60.

[0047] Such as figure 1 As shown, a kind of FeNiAlNb-based pin shaft multilayer composite structure material tribological design and preparation method thereof specifically include the following steps:

[0048] 1) Preparation of multi-layer plate crystal MoBNbO: Weigh ammonium molybdate, boron powder and niobium powder with an average particle size of 40 μm in a molar ratio of 5:2:2, finely grind the ammonium molybdate, boron powder and niobium powder After mixing; then the powder is placed in a vacuum atmosph...

Embodiment 3

[0057] A FeNiAlNb-based pin multi-layer composite structure material, with FeNiAlNb material as the matrix, friction reducer, anti-wear agent, and reinforcing agent as components, compositely forms a FeNiAlNb-based pin multi-layer structure, the structure is divided into friction film, The three-layer composite structure of the bearing transition layer and the base bearing layer, the thickness ratio of each layer is 8:25:67.

[0058] Such as figure 1 As shown, above-mentioned a kind of FeNiAlNb-based pin shaft multi-layer composite structure material tribological design and preparation method thereof specifically include the following steps:

[0059] 1) Preparation of multi-layer plate crystal MoBNbO: Weigh ammonium molybdate, boron powder and niobium powder with an average particle size of 45 μm in a molar ratio of 5:3:2, finely grind the ammonium molybdate, boron powder and niobium powder After mixing; then the powder is placed in a vacuum atmosphere furnace, and the sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com