Powerful anti-friction energy-saving gasoline engine oil and production technology thereof

A gasoline engine oil, anti-friction technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of non-compliance with environmental protection standards, shortened service life, poor quality of gasoline engine oil, etc., and achieve good high-temperature oxidation resistance and low-temperature fluidity, Less wear and less volatilization loss

Inactive Publication Date: 2018-11-23

王兴民

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the product purity of this patented product is poor, which will shorten the service life. The lubricating oil is added with a micro-fluorine series engine wear protection agent, which makes the introduction of fluorine-containing compounds into the engine oil product, which will aggravate air pollution and does not meet the environmental protection standards of today's society. , and the product contains more impurities, phosphorus and sulfur, and the quality of gasoline engine oil is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

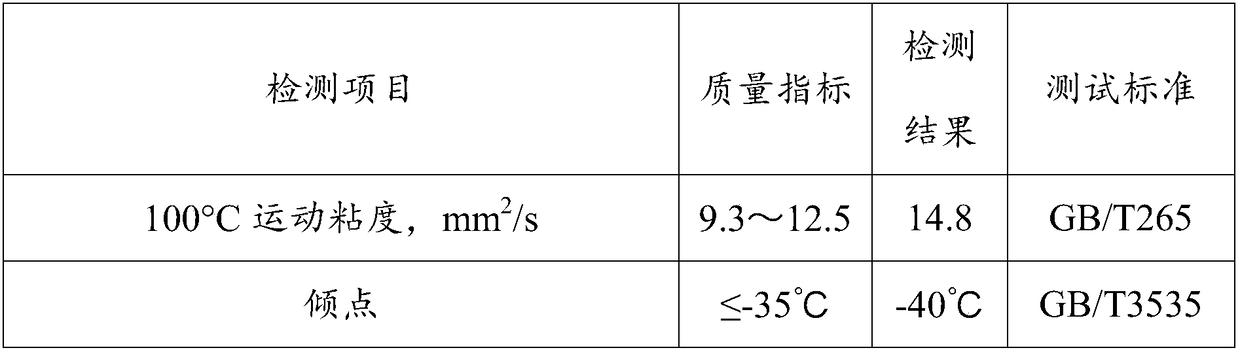

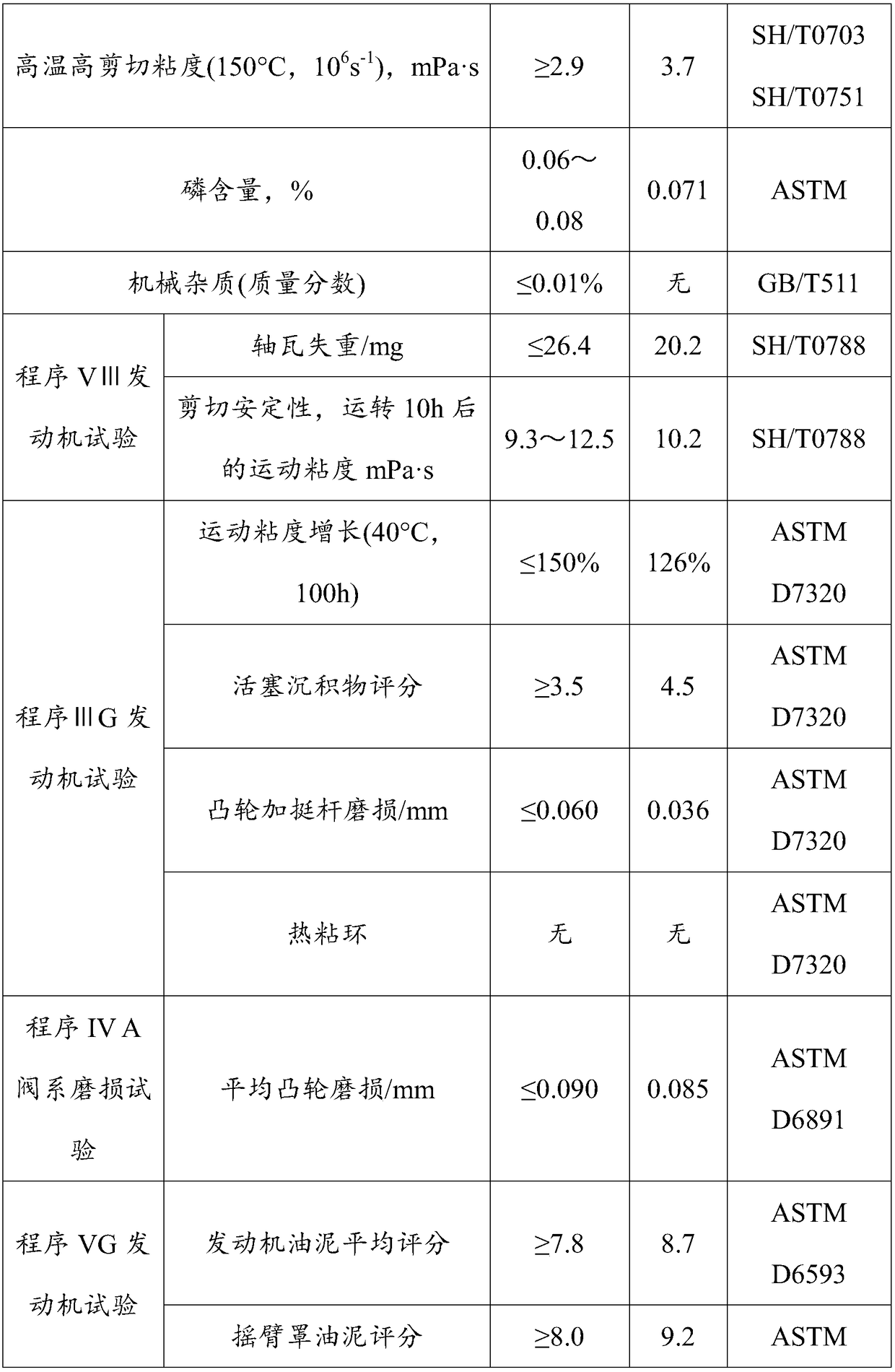

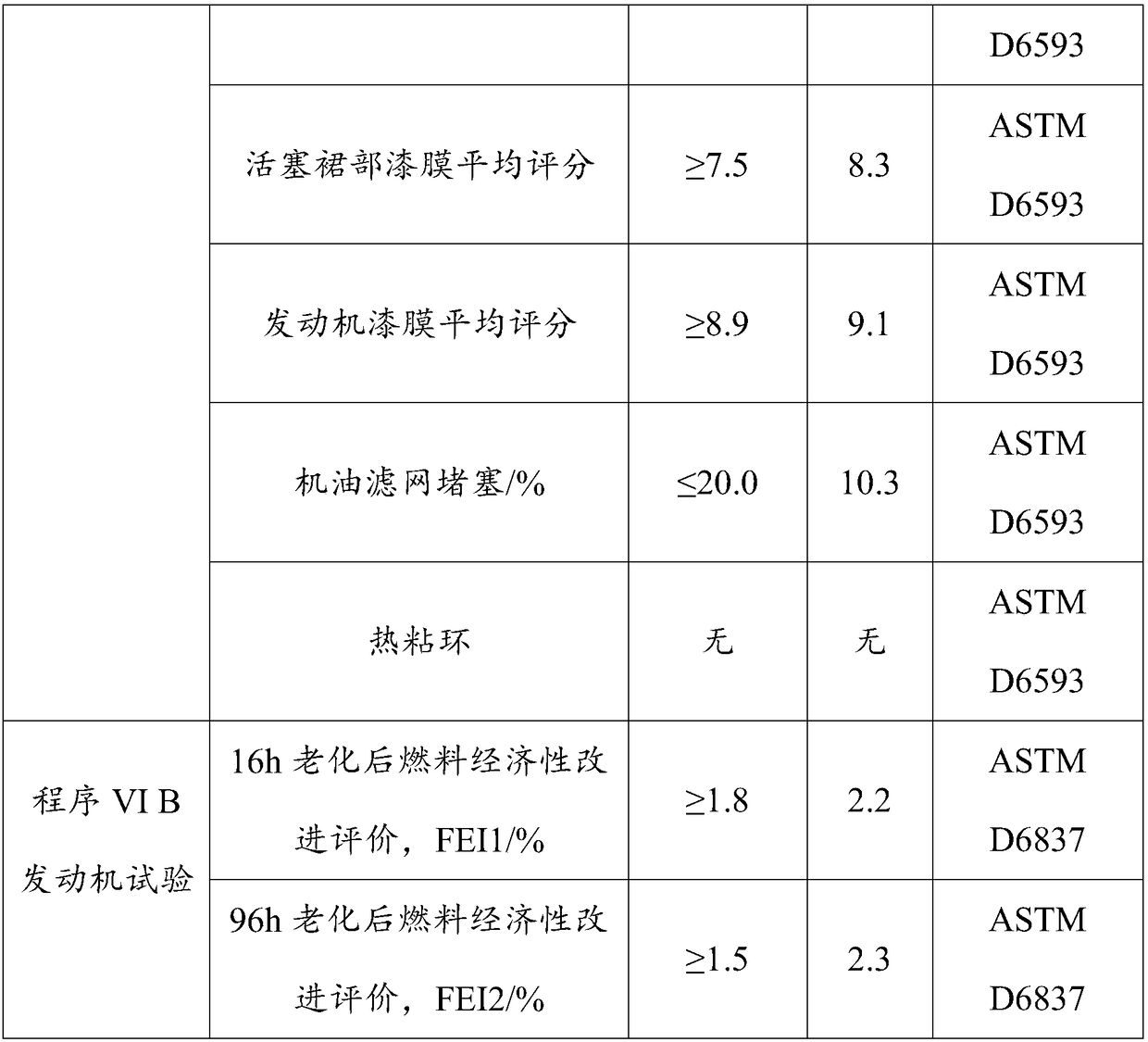

[0036] A strong anti-friction energy-saving gasoline engine oil was prepared according to production process 1 with formula 1.

Embodiment 2

[0038] A strong anti-friction and energy-saving gasoline engine oil was prepared by formula 1 and production process 2.

Embodiment 3

[0040] A strong anti-friction and energy-saving gasoline engine oil was prepared by formula 1 according to production process 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses powerful anti-friction energy-saving gasoline engine oil and a production technology thereof. The powerful anti-friction energy-saving gasoline engine oil is prepared form thefollowing raw materials: synthetic base oil, a metal detergent, an ashless dispersant, an anti-oxidation and anti-corrosion agent, a nano-scale multi-effect abrasive, a viscosity index improver and apour point depressant. The production technology comprises the following steps: putting the synthetic base oil in a reaction kettle, starting stirring, and heating; putting the pour point depressant,the viscosity index improver, the anti-oxidation and anti-corrosion agent, the metal detergent and the ashless dispersant in sequence, and uniformly stirring; then putting the nano-scale multi-effectabrasive, and continuing to stir at a certain rotating speed by keeping the original temperature; finally, pumping the stirred materials to a storage tank, and standing for 1 hour, thus obtaining a finished product of the powerful anti-friction energy-saving gasoline engine oil. According to the powerful anti-friction energy-saving gasoline engine oil and the production technology thereof, disclosed by the invention, the production conditions are easy to control; fuel produced by the invention is good in economy and long in oil draining period, and excellent anti-abrasion and anti-friction performance, high-temperature oxidation resistance and low-temperature fluidity are obtained.

Description

technical field [0001] The invention relates to the field of lubricating compositions, in particular to a powerful anti-friction energy-saving gasoline engine oil and a production process thereof. Background technique [0002] With the rapid development of the automobile industry, people's requirements for vehicle maintenance are getting higher and higher, and the competition in the automotive lubricant market is also intensifying. Green environmental protection, high anti-friction, and energy saving will become the development direction of a new generation of automotive lubricants. Synthetic lubricants The oil will also be used more for the lubrication protection of the engine oil. Compared with mineral oils, synthetic oils have excellent low-temperature fluidity, outstanding high-temperature oxidation resistance, and stronger anti-wear capabilities. The viscosity change of synthetic lubricating oil is little affected by temperature. It can not only flow under low temperat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/02C10N30/04C10N30/06C10N30/08C10N30/10C10N40/25

CPCC10M169/048C10M2201/087C10M2203/06C10M2205/022C10M2205/024C10M2205/026C10M2205/0285C10M2205/04C10M2205/06C10M2207/144C10M2207/2835C10M2207/2855C10M2209/04C10M2209/102C10M2215/064C10M2215/086C10M2219/068C10M2219/089C10M2223/045C10M2227/06C10N2030/02C10N2030/04C10N2030/06C10N2030/08C10N2030/10C10N2030/56C10N2040/255C10N2020/081C10N2020/06C10N2010/04C10N2060/02

Inventor 王兴民

Owner 王兴民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com