Spray supply mode cutting oil for metal material cutting processing

A cutting and metal material technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of diffusion wear, difficult cutting, large elongation, etc. The effect of viscosity-temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

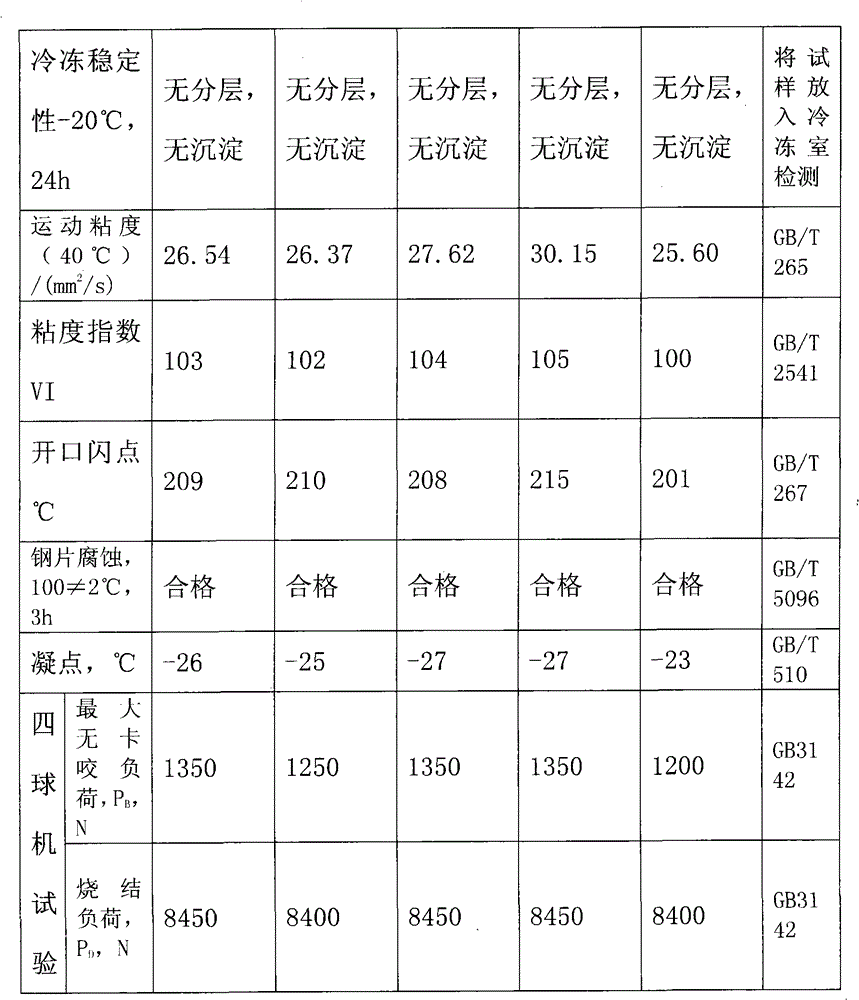

Embodiment 1

[0048] Add 150 grams of oxidized rapeseed oil and 400 grams of trimethylolpropane oleate to 190 grams of vulcanized lard, 150 grams of vulcanized rapeseed oil, 50 grams of tricresyl phosphate and 50 grams of di-n-butyl phosphite in sequence at room temperature Phosphate esters composed of esters, 10 grams of polybutylene, and kept at room temperature and stirred for 30 minutes at a stirring speed of 100-120 rpm, stirred until completely transparent and then packaged.

Embodiment 2

[0050] With 100 grams of oxidized rapeseed oil and 400 grams of trimethylolpropane oleate, add 150 grams of vulcanized lard, 150 grams of sulfurized rapeseed oil, 95 grams of tricresyl phosphate and 95 grams of di-n-butyl phosphite in sequence at room temperature Phosphate esters composed of esters, 10 grams of ethylene-propylene copolymer, and kept at room temperature and stirred for 30 minutes at a stirring speed of 100-120 rpm, stirred until completely transparent and then packaged.

Embodiment 3

[0052] 300 grams of trimethylolpropane oleate, 100 grams of oxidized rapeseed oil and 150 grams of isobutyl stearate were added successively at room temperature to 150 grams of vulcanized lard, 190 grams of sulfurized rapeseed oil, and 50 grams of trimethylbenzene phosphate Phosphate ester composed of ester and 50 grams of triethyl phosphate, 10 grams of hydrogenated styrene copolymer, and kept at room temperature and stirred for 30 minutes at a stirring speed of 100-120 rpm, until completely transparent and then packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com